Share this

PLA Recycling: Everything You Need to Know

by 3devo on Jun 17, 2024 3:07:10 PM

Plastic waste is a growing global concern, and 3D printing, while innovative, contributes to this problem. PLA (Polylactic Acid) is one of the most popular 3D printing materials, but how can it be recycled to mitigate its environmental impact? This article delves into the recycling process for PLA, explores its biodegradability, and provides practical tips to reduce 3D printing waste, using various methods including our advanced recycling solutions.

Can You Recycle 3D Printer Filament?

3D printer filaments, such as PLA, are made from thermoplastic materials that can melt and re-solidify. This characteristic makes them recyclable. However, local recycling centers often do not accept PLA as it falls under “Type 7” plastics. To recycle PLA effectively, companies can utilize specialized recycling facilities or employ a professional-grade filament extruder like our Filament Maker.

Can You Recycle PLA?

PLA, derived from plant starches, is both recyclable and compostable. However, it must be recycled separately from other plastics to avoid contamination due to its lower melting point. Industrial composting facilities can biodegrade PLA under controlled conditions, but home composting is generally ineffective. Recycling at an industrial level using a filament extruder ensures high-quality filament production and sustainability.

Recycling Processes for PLA

Mechanical Recycling

Mechanical recycling involves shredding PLA waste, washing it to remove contaminants, drying, and then re-extruding it into new filament. This method is energy-efficient but can degrade the material’s properties over multiple cycles. Our GP20 Shredder & Granulator paired with the Filament Maker provides a seamless and efficient solution for mechanical recycling, ensuring high-quality filament output.

Chemical Recycling

Chemical recycling breaks down PLA into its monomers or other chemicals using processes like hydrolysis, methanolysis, or glycolysis. This method can handle higher contamination levels and produces high-quality recycled material but is more energy-intensive. While effective, this method is often better suited for specialized applications where high purity is required.

Industrial Filament Extrusion

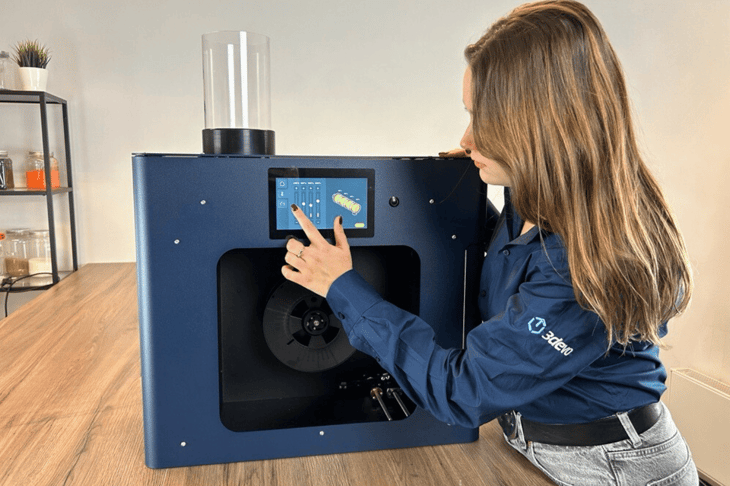

Industrial filament extrusion is ideal for companies and institutions aiming to recycle large volumes of PLA waste. Determining the optimal recycling parameters for your particular grade of PLA can be a challenging task when using an industrial filament extrusion machine, as it involves rigorous testing and experimentation. This is where our solution comes in place. With our Filament Maker, organizations can experiment and transform their plastic waste into high-quality filament, in smaller batches, promoting a circular economy and reducing environmental impact. Eventually they can decide if they want to move to a bigger scale filament extrusion system. This method is cost-effective, scalable, and ensures consistent filament quality, making it a preferred choice for professional use.

Benefits of Using Professional-Grade Filament Extruders

Investing in a professional-grade filament extruder offers numerous advantages, including:

- Cost Savings: Recycling PLA waste into new filament reduces material costs.

- Quality Control: Ensures consistent filament quality, crucial for professional applications.

- Environmental Impact: Reduces plastic waste and promotes sustainable practices.

- Scalability: Our flexible business model allows you to build a filament extrusion farm, suitable for large-scale operations, making it ideal for companies and institutions.

How to Reduce Plastic Waste

Minimize Support Materials

Design your 3D models to require fewer supports and use software to adjust support settings, reducing waste. This not only saves material but also reduces post-processing time.

Proper Bed Adhesion

Ensure your first layer adheres well to the print bed to prevent failed prints and wasted material. Using the right bed adhesive and ensuring a level print bed can significantly reduce print failures.

Regular 3D Printer Maintenance

Maintain your 3D printer to reduce print failures and material waste. Regular maintenance includes cleaning the nozzle, checking the bed level, and ensuring that the filament path is clear.

Using Recycled Filaments

Opt for filaments made from recycled materials to support a circular economy. Our solutions allow companies to create high-quality recycled filaments, promoting sustainability and reducing costs. By choosing recycled filaments, you help reduce the demand for new plastic production.

Invest in a Professional-Grade Filament Extruder

Consider investing in a professional-grade filament extruder like our Filament Maker to recycle your 3D printing waste efficiently and sustainably. This investment pays off by providing a consistent supply of high-quality filament and reducing your environmental footprint.

Practical Tips for PLA Recycling

Sorting and Cleaning PLA Waste

Before recycling PLA, it's essential to sort and clean the waste. This involves separating PLA from other types of plastics and removing any contaminants, such as food particles or adhesives. Clean PLA waste ensures higher quality recycled filament.

Shredding and Granulating

Shredding PLA waste into smaller pieces makes it easier to process. Our GP20 Shredder & Granulator efficiently handles this task, preparing the waste for extrusion.

Extruding New Filament

Once the PLA waste is shredded and cleaned, it can be extruded into new filament using our Filament Maker. This process involves melting the shredded PLA and forming it into a continuous filament, ready for use in 3D printing.

Case Study: Successful PLA Recycling

There are several success stories that highlight how sectors ranging from education to automotive manufacturing can leverage 3devo’s recycling solutions to achieve sustainability goals, reduce costs, and foster innovation. By transforming plastic waste into valuable resources, organizations contribute to a more sustainable future. Notable examples include:

- Educational Institutions: Fontys University of Applied Sciences integrated 3devo's Composer 450 Filament Maker into their curriculum, enabling students to gain hands-on experience in polymer extrusion and recycling. This approach facilitated the development of sustainable polymers and reduced reliance on large-scale extrusion machinery, thereby minimizing material waste and associated costs. Read the full case study here.

- Automotive Industry: Audi implemented 3devo's full suite of recycling machines—including the Shr3d It plastic shredder, Airid polymer dryer, and Precision 450 Filament Maker—to repurpose plastic waste into 3D-printed tools. This initiative supported their "Mission: Zero" project, aiming for net-zero carbon emissions by 2025, and exemplified sustainable practices within large-scale manufacturing. Read the full case study here

Future of PLA Recycling

As technology advances, the future of PLA recycling looks promising. Innovations in recycling methods, such as more efficient chemical recycling processes and improvements in mechanical recycling, will enhance the sustainability of 3D printing. Our commitment to developing cutting-edge solutions ensures that we remain at the forefront of these advancements.

Conclusion

3D printing with PLA has an environmental impact, but recycling and waste reduction strategies can help mitigate it. While local recycling options may be limited, industrial recycling facilities, professional-grade equipment, and sustainable practices can make a significant difference. Our innovative products support your efforts to recycle PLA efficiently and contribute to a more sustainable future.

By incorporating our solutions, companies can effectively recycle PLA and contribute to a sustainable future. Explore our products to start your recycling journey today!

Frequently Asked Questions (FAQs)

PLA (Polylactic Acid) is a biodegradable plastic made from renewable resources like corn starch and sugarcane, commonly used in 3D printing.

PLA can be recycled mechanically by shredding and re-extruding or chemically by breaking it down into monomers. Our solutions provide efficient mechanical recycling methods.

Yes, PLA is biodegradable under industrial composting conditions but not in regular landfills.

While it is possible, it is more efficient for companies to use professional-grade equipment like our Filament Maker for higher quality and consistency.

Recycling PLA reduces waste, conserves resources, and lowers greenhouse gas emissions compared to producing new PLA. Our solutions help achieve these benefits at an industrial scale.

Share this

- November 2025 (1)

- October 2025 (1)

- March 2025 (1)

- January 2025 (1)

- December 2024 (2)

- November 2024 (2)

- October 2024 (4)

- September 2024 (2)

- August 2024 (3)

- July 2024 (6)

- June 2024 (3)

- May 2024 (2)

- April 2024 (1)

- March 2024 (1)

- January 2024 (1)

- November 2023 (2)

- October 2023 (5)

- September 2023 (2)

- August 2023 (1)

- July 2023 (1)

- May 2023 (1)

- December 2022 (2)

- June 2022 (1)

- May 2022 (2)

- April 2022 (2)

- March 2022 (6)

- February 2022 (2)

- January 2022 (3)

- December 2021 (3)

- November 2021 (3)

- October 2021 (2)

- September 2021 (3)

- August 2021 (3)

- July 2021 (2)

- June 2021 (1)

- March 2021 (1)

- October 2020 (1)

- June 2020 (1)

- May 2020 (1)

- April 2020 (4)

- November 2019 (1)

- July 2019 (2)

- June 2019 (1)

- May 2019 (1)

- March 2019 (1)

- November 2018 (1)

- September 2018 (1)

- January 2018 (1)

- October 2017 (1)

- September 2017 (1)

- July 2017 (1)

- June 2017 (1)

- May 2017 (1)

- January 2017 (1)

- December 2016 (3)

- November 2016 (2)

- October 2016 (1)

- May 2016 (2)

- August 2015 (2)

- July 2015 (1)