Share this

Gauging our Impact in Filament-Making: Formnext 2024 Recap

by Ellie Pritchard on Dec 5, 2024 11:36:00 AM

It’s a wrap! Another year, another incredibly successful Formnext Expo in Frankfurt! We spent a week interacting in person with the innovators, trailblazers, researchers, and educators of the 3D printing industry, discussing the various capabilities of our desktop filament making process.

There is nothing quite like meeting in person, and we were delighted to welcome so many people to our stand across the four exhibition days. Our team was busy from Tuesday to Friday, introducing potential new customers to our machines and services, and catching up with existing partners, sharing project experiences and considering pathways for further progress.

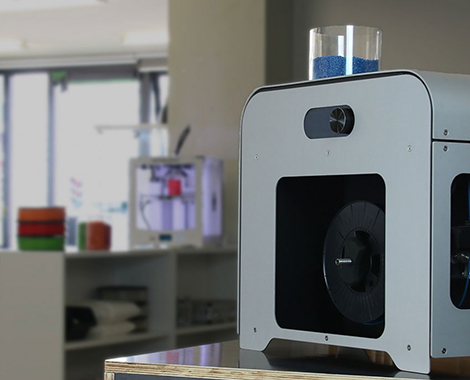

And, of course, at the center of this was our newly launched Filament Maker TWO! Taking pride of place at the front of our booth, the brand new, fully realized Filament Maker TWO drew crowds of people curious to learn about the machine’s capabilities and improved features. As well as the new machine, we also presented our original Filament Maker ONE, our GP20 Shredder, a standalone demonstration model of our new filament sensor, and a Bambu Lab printer to showcase successful FDM printing with our filament.

Now settled back in our Utrecht office, we spoke with our team to find out their top highlights from the event. From handing over the first Filament Maker TWO to its new owner, to collaborating with industry partners, there are a lot of highlights to share!

First Filament Maker TWO Customer!

One of the most memorable moments for us at Formnext 2024 was delivering our very first Filament Maker TWO to a customer during the event! This milestone marked the culmination of an exciting journey that began at Formnext 2023 when MSV Studénka, a Czech company sharing our passion for sustainable innovation, discovered our filament makers and immediately saw their potential. Driven by their ambitious goals in composite material research, they immediately saw the potential of our Filament Makers, falling in love with the Filament Maker TWO prototype. Due to time constraints and the urgency of their project, the MSV Studénka team decided to first rent our original Filament Maker ONE, visiting our Utrecht office for a hands-on training session to ensure efficient onboarding. Now, just a year later, we proudly handed over the Filament Maker TWO at their booth, ready to support their cutting-edge work in reinforcing PEEK, PC, and ABS with recycled carbon fibers and other additives.

MSV Studénka’s commitment to sustainability and innovation is truly inspiring, and we’re excited to see how they leverage the Filament Maker TWO to advance composite research and unlock new possibilities. For more about their incredible projects, visit their site.

This milestone encapsulates everything we love about Formnext—collaboration, innovation, and the power to help shape a sustainable future through technology!

Live Machine Demonstrations

In a fair as vast as Formnext, there are countless exhibitors vying for the attention of thousands of visitors. And what better way to motivate people to take a closer look than with live demonstrations? At an event saturated with 3D printers of all shapes and sizes, 3devo benefits from belonging to the relatively niche field of desktop filament extrusion. As the only compact and genuinely desktop-sized filament extrusion system, we set ourselves apart from our more space consuming competitors - but we know that seeing really is believing.

From our booth, we demonstrated our full recycling solution, from on-site shredding with our GP20 Plastic Shredder, to extrusion from both the original Filament Maker ONE and our newly launched Filament Maker TWO, to using this same filament to print mini Filament Makers with our Bambu Labs printer. Showing the full lifecycle of plastic waste to new resource gave us the perfect opportunity to show visitors exactly how the process could work for them and their materials, whether their projects required recycled plastic, complex compounds and additives, or standard virgin materials.

Having our full team of Materials Specialist present at the stand also meant prospective customers could experience firsthand the level of knowledge and expertise they would have access to upon commencing a project with 3devo. You can learn more about our experienced team of Materials Specialists through their dedicated team page and discover how they work together with you to bring your project to success.

Collaborations and Partnerships

As well as an opportunity to grow our community, events such as Formnext also give the chance for us to deepen our connections with our existing network. In our preparations for the expo, we were delighted to discover that our neighbors would be BigRep, a leader in large-format additive manufacturing solutions. As our new Filament Maker TWO is now capable of producing 3kg spools of filament, we reached out to BigRep to offer a collaboration in which we would produce a large spool of filament ideal for their large-scale printers extruded from their own waste material. Following an initial testing phase, it was agreed that our friends at BigRep would provide several kilos of broken down support parts to be shredded and repurposed into new FDM filament.

On the first day of the event, BigRep’s Senior Applications Specialist Michael Eggerdinger carried over a box of Carbon Fiber PLA-based biopolymer parts to the 3devo stand, exchanging this for the spool of filament our Materials Specialists had already extruded in our 3devo lab from the initial test sample. Michael was able to install the spool in their BigRep VIIO 250 on the BigRep stand straight away, whilst our team used the carbon fiber waste material to demonstrate the 3devo GP20 Plastic Shredder throughout the rest of the event. A huge success, we were very happy to be showcasing the recycling capabilities of our filament extrusion system in real life!

As part of our live demonstrations, we extruded filament from virgin PLA mixed with pellets of our 3devo custom color Masterbatch pellets developed and provided by our customer, GRAFE. Thanks to the incredibly high color concentration of these pellets, the mix requires only 2-3%! The filament extruded during our time at Formnext was consistent and of such a high quality, we were delighted to be able to share samples with stand visitors. We caught up with our friends at GRAFE at their stand during the event, chatting with Sebastiaan Grafe (Head of Sales Export) about their experience using our original Filament Maker ONE almost from the very first model in 2018! We recorded the full interview for our YouTube channel, so be sure to watch and learn more about GRAFE’s solutions.

From Waste to Art

Attending events such as Formnext enables our team the chance to meet with companies and organizations that we usually only get to learn about online. One such example is the futuristic artist duo, SUTOSUTO, based in Germany. We were delighted to chat with the SUTOSUTO team (comprising of Susanne Dallmayr and Thomas Koch) at their Formnext stand about the ways in which they combine engineering and additive manufacturing processes with traditional artistic formats to create large-scale canvases and sculptures. Equipped with one of our own Filament Maker ONEs, the duo can even incorporate recycled plastic into their art, repurposing waste materials into impressive structures. We are excited to explore ways in which 3devo and SUTOSUTO can collaborate in the future, so watch this space!

In a similar vein, we were also visited by Bruno Tognin, a Brazilian artist based in France, who integrates 3D printing and artificial intelligence into his artistic creations and fashion projects. Bruno makes use of a 3devo Filament Maker ONE to transform waste plastic and support materials from other prints into new filament, ready to print intricate designs and wearable pieces that showcase the value of repurposed materials. Check out Bruno's instagram post below to see how he upcycled 23kg of plastic waste into a Christmas tree that doubles up as a cozy coffee corner!

It is so inspiring for our team to learn about the creative and beautiful ways in which recycled filament made with our machines are being used. Whether the application is technical and focused on materials innovation or geared more towards an artistic direction, we find so much joy in contributing to these creations with our knowledge, expertise, and machines.

Conclusion

Another year of Formnext madness has come to a close and we feel grateful for yet another successful and inspiring experience. As mentioned before, nothing compares to meeting with our customers in person. An opportunity to share excitement and the momentum of innovation, Formnext 2024 has once again proven to be an unforgettable milestone for our team at 3devo. From handing over the first Filament Maker TWO to hearing how our machines empower groundbreaking research, partnerships, and art, the event showcased the incredible potential of collaboration and creativity. Whether it was through live demonstrations of our recycling solutions, partnerships with organizations like BigRep, or connecting with creatives who transform waste into art, Formnext highlighted how technology can bridge diverse industries and spark positive change. As we return to our Utrecht office, energized and inspired, we look forward to continuing these conversations, strengthening partnerships, and driving innovation to create a more sustainable and resourceful future. See you at the next Formnext!

Discover our new Filament Maker TWO

Learn more about our new Filament Maker TWO - a powerful filament extruder and filament research platform in one machine.

Frequently Asked Questions (FAQs)

Formnext is the leading international trade fair for additive manufacturing and industrial 3D printing. It’s a hub for innovation, collaboration, and showcasing the latest advancements in the industry. For 3devo, it’s an opportunity to connect with partners, customers, and innovators while unveiling new technologies like the Filament Maker TWO.

The Filament Maker TWO builds on the success of the Filament Maker ONE with improved features, including enhanced extrusion precision, greater compatibility with composite materials, and the ability to produce larger 3kg spools, making it ideal for both research and large-scale production applications.

Absolutely! The Filament Maker TWO is designed to process recycled plastic waste, allowing users to create high-quality filament for 3D printing. It’s part of our full recycling solution, which includes the GP20 Plastic Shredder for on-site material preparation.

3devo offers comprehensive support through our team of Materials Specialists, who provide training, technical assistance, and personalized guidance to ensure your projects are successful. Our experts work closely with customers to optimize materials and processes.

The Filament Maker TWO is versatile and benefits industries ranging from research and development (e.g., composite material innovation) to education, sustainable manufacturing, and creative fields like art and design. Its adaptability makes it suitable for diverse applications.

You can follow us on social media, subscribe to our newsletter, and visit our website for the latest updates, insights, and success stories from 3devo and our customers. Don’t forget to check out our blog for deep dives into our projects and industry trends!

Begin Your Journey Towards Sustainable 3D Printing

Start by transforming plastic waste into recyclable material with our efficient and innovative shredder, designed to empower your filament recycling journey.

.jpg?width=865&height=500&name=GP20-Shredder-Hybrid-1%20(2).jpg)

Explore More on Sustainable 3D Printing Materials

Recycle Plastic Waste

Transform plastic waste into quality 3D printing filament and join our mission for responsible innovation with 3devo's complete recycling solution.

%20-%20instasize.png?width=800&height=640&name=which-plastics-are-recyclable%20(1)%20-%20instasize.png)

Which Plastics are recyclable?

Understand different plastic types and their recyclability to make informed decisions on selecting the right material for your needs.

%20-%20instasize%20(1).png?width=800&height=640&name=PETG-e1494958102567%20(1)%20-%20instasize%20(1).png)

How to recycle PET into Filament?

Discover how PET plastic is transformed into eco-friendly 3D printing filaments on our dedicated Recycling PET page.

Share this

- March 2025 (1)

- January 2025 (1)

- December 2024 (2)

- November 2024 (3)

- October 2024 (4)

- September 2024 (2)

- August 2024 (3)

- July 2024 (6)

- June 2024 (3)

- May 2024 (2)

- April 2024 (1)

- March 2024 (1)

- January 2024 (1)

- November 2023 (2)

- October 2023 (5)

- September 2023 (2)

- August 2023 (1)

- July 2023 (1)

- May 2023 (1)

- December 2022 (3)

- August 2022 (1)

- June 2022 (1)

- May 2022 (2)

- April 2022 (2)

- March 2022 (7)

- February 2022 (2)

- January 2022 (3)

- December 2021 (3)

- November 2021 (3)

- October 2021 (2)

- September 2021 (3)

- August 2021 (3)

- July 2021 (2)

- June 2021 (1)

- March 2021 (1)

- October 2020 (1)

- June 2020 (1)

- May 2020 (1)

- April 2020 (4)

- November 2019 (1)

- July 2019 (2)

- June 2019 (1)

- May 2019 (1)

- March 2019 (1)

- November 2018 (1)

- September 2018 (1)

- January 2018 (1)

- October 2017 (1)

- September 2017 (1)

- July 2017 (1)

- June 2017 (1)

- May 2017 (1)

- January 2017 (1)

- December 2016 (3)

- November 2016 (2)

- October 2016 (1)

- May 2016 (2)

- August 2015 (2)

- July 2015 (1)