Full Recycling Solution

Recycle plastic from start to finish with our end-to-end plastic recycling system - everything you need in one place for seamless, efficient results.

Transforming Plastic Waste into Innovation

Imagine turning plastic waste into a valuable resource, ready for the next round of innovation. With our end-to-end recycling system, you get everything needed to create high-quality filament from start to finish. Designed to be seamless, efficient, and empowering, our solution transforms your recycling goals into achievable actions, all within one integrated setup.

Our Recycling Set

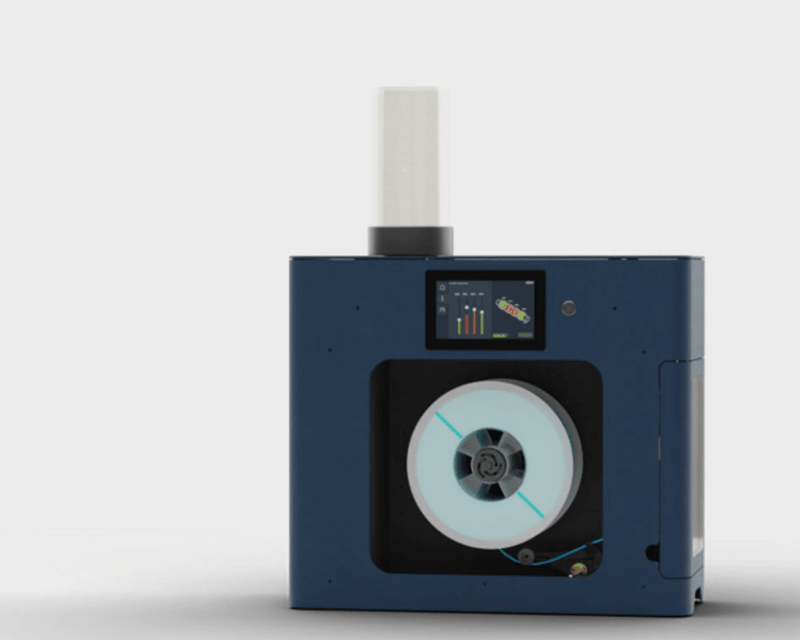

Filament Makers

Our Filament Makers convert raw or recycled materials into custom, high-quality 3D printing filaments, facilitating innovation from prototyping to sustainable production.

Vismec DW14 Desiccant Dryer

The Desiccant Dryer ensures perfect filament by removing moisture, enhancing extrusion quality and consistency, essential for optimal 3D printing.

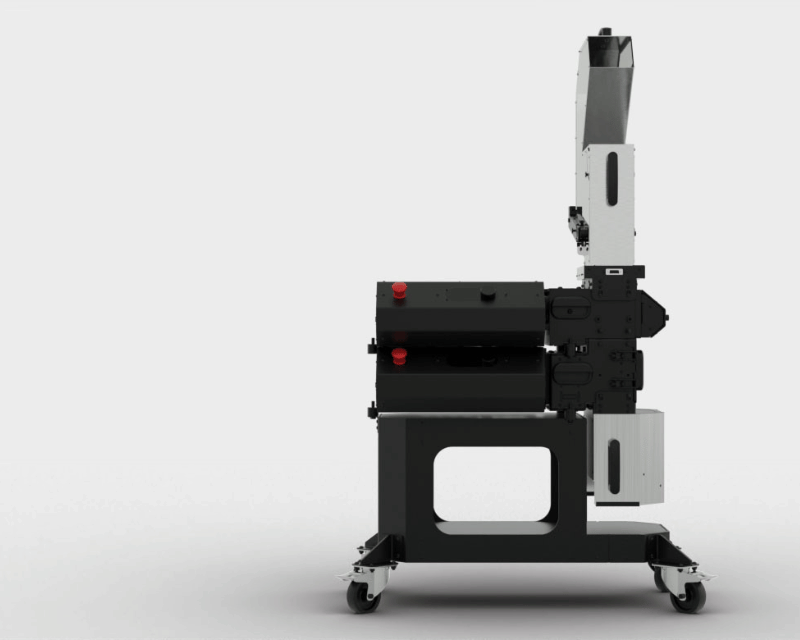

Plastic Shredder

Our Plastic Shredder efficiently converts plastic waste into granules for extrusion, making sustainable 3D printing accessible and impactful.

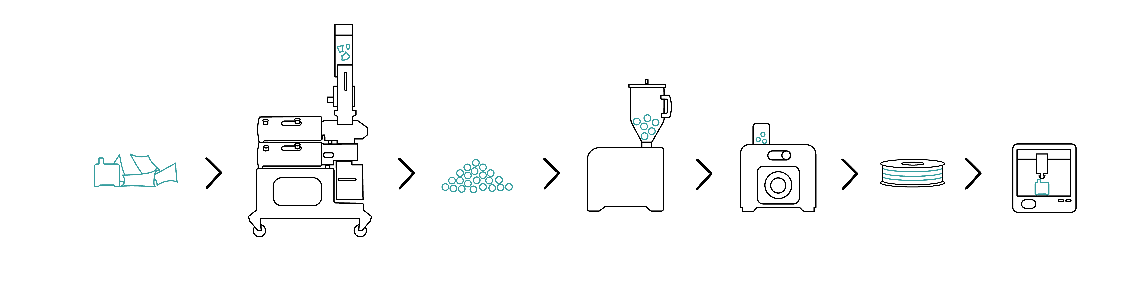

A Complete Workflow, Start to Finish

Guidance By Our Experts

Our Experts guide you from setup to filament production, ensuring smooth operations tailored insights every step of the way.

Shredding

Shred your plastic waste into process-ready granules using our GP20 Plastic Shredder.

Drying

Remove moisture from your shredded plastic with a polymer dryer, prepping it for high-quality extrusion.

Extruding

Use our Filament Makers to transform granulated plastic into custom filament, perfect for your 3D printing projects.

Trusted By the World's Top Engineers and Researchers:

What Makes Our Solution Special?

Empowering sustainable innovation through adaptable, high-quality recycling tools for every stage of the process.

Built-In Expertise & Support

Our Extrusion team guides you every step of the way, ensuring you get the most from your recycling system.

Seamless Integration

Our machines sync perfectly, creating a smooth, end-to-end workflow that keeps you focused on results.

Versatitlity

From standard plastics to complex composites, our setup easily adapts to your unique recycling needs.

Compact Power for Any Space

From labs & classrooms to production halls and fablabs, our machines combine industrial-grade functionality in a compact, user-friendly format.

Less Guesswork, More Data

Our advanced monitoring system tracks temperature and speed in real-time, ensuring filament consistency and allowing on-the-fly adjustments to prevent issues.

Get Reliable Filament Every Time

Our Filament Makers deliver consistent, high-quality filament with customizable settings to match your project’s unique needs.

Dual-Function Shredder & Granulator

Get perfect granules in one go. The 3devo shredder combines shredding and granulation to deliver uniform material, ready for extrusion—no extra steps needed.

Scalable for Growing Needs

As your projects and production scale, our recycling system adapts effortlessly, allowing you to easily expand your setup and keep pace with evolving requirements.

Compare Recycling Solutions

How Our Full Solution Helped Audi Lead in Sustainability

Audi faced a challenge: reducing plastic usage while maintaining high-quality production standards. Our complete recycling solution provided the answer, enabling them to transform plastic waste into valuable new filament for 3D-printed tooling—all while advancing sustainability and efficiency. With seamless support from our Extrusion Experts, Audi implemented a scalable model that cuts waste, meets production demands, and supports their environmental goals.

Discover the full story of how Audi leveraged our recycling system to drive sustainable innovation.

Ready to Get Started?

Frequently Asked Questions

Yes, the 3devo Full Recycling Solution is built to handle a variety of plastics. From everyday options like PLA and ABS to more complex, high-performance materials like PEEK and PEKK, our system is designed for flexibility. Our Filament Maker ONE and TWO machines and GP20 Plastic Shredder support a range of temperatures and extrusion paths to accommodate various polymers, ensuring high-quality filament production regardless of material type. For a deeper look into compatible materials, see our Materials page.

Yes, the GP20 Shredder is designed to produce granulates that are ready for use in the Filament Maker without further processing. The shredded plastic granules are of optimal size, ensuring smooth feeding and consistent extrusion. The integration of these two machines creates a streamlined workflow, reducing the steps and time needed to produce filament from recycled material.

Our Full Recycling Solution supports various sectors, from research institutions and universities to manufacturing and engineering firms. Labs often use the system to develop new materials, while manufacturers and businesses leverage it for sustainable practices by recycling plastic waste into reusable filament. To see real-world applications, visit our Case Studies page to learn how customers in different industries are achieving their recycling goals.

Using an integrated setup like the 3devo Full Recycling Solution reduces compatibility issues and enhances overall efficiency. Each component—the shredder, dryer, and filament maker—is designed to function seamlessly together, minimizing the need for adjustments and manual interventions. This system saves time, reduces waste, and ensures consistent filament quality. Learn more about our integrated approach on the How We Work page.

Check out our Recycling Innovations

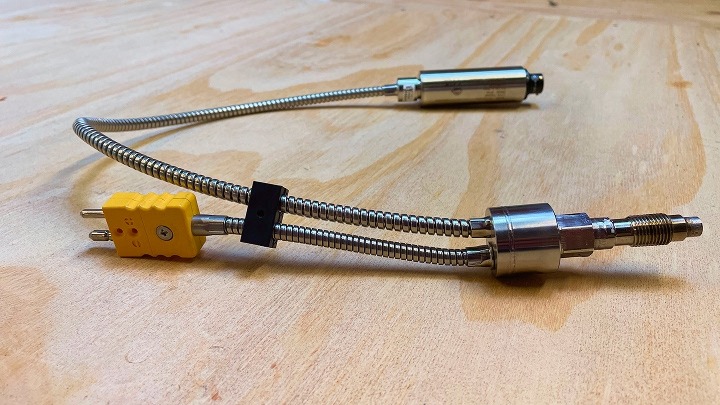

How We're Developing a Pressure Sensor for the Extrusion Process

Filament Maker TWO vs. Alternatives: Compare Filament Extruders

3devo 2024 Highlights: Reflecting on a Year of Growth and Change