Share this

3devo Customer Success Team Evolution: From Reactive to Proactive

by Benjámin Beregszászi on Nov 11, 2024 2:05:28 PM

.jpg?width=1044&height=731&name=3devo_Esa_photo30%20(1).jpg)

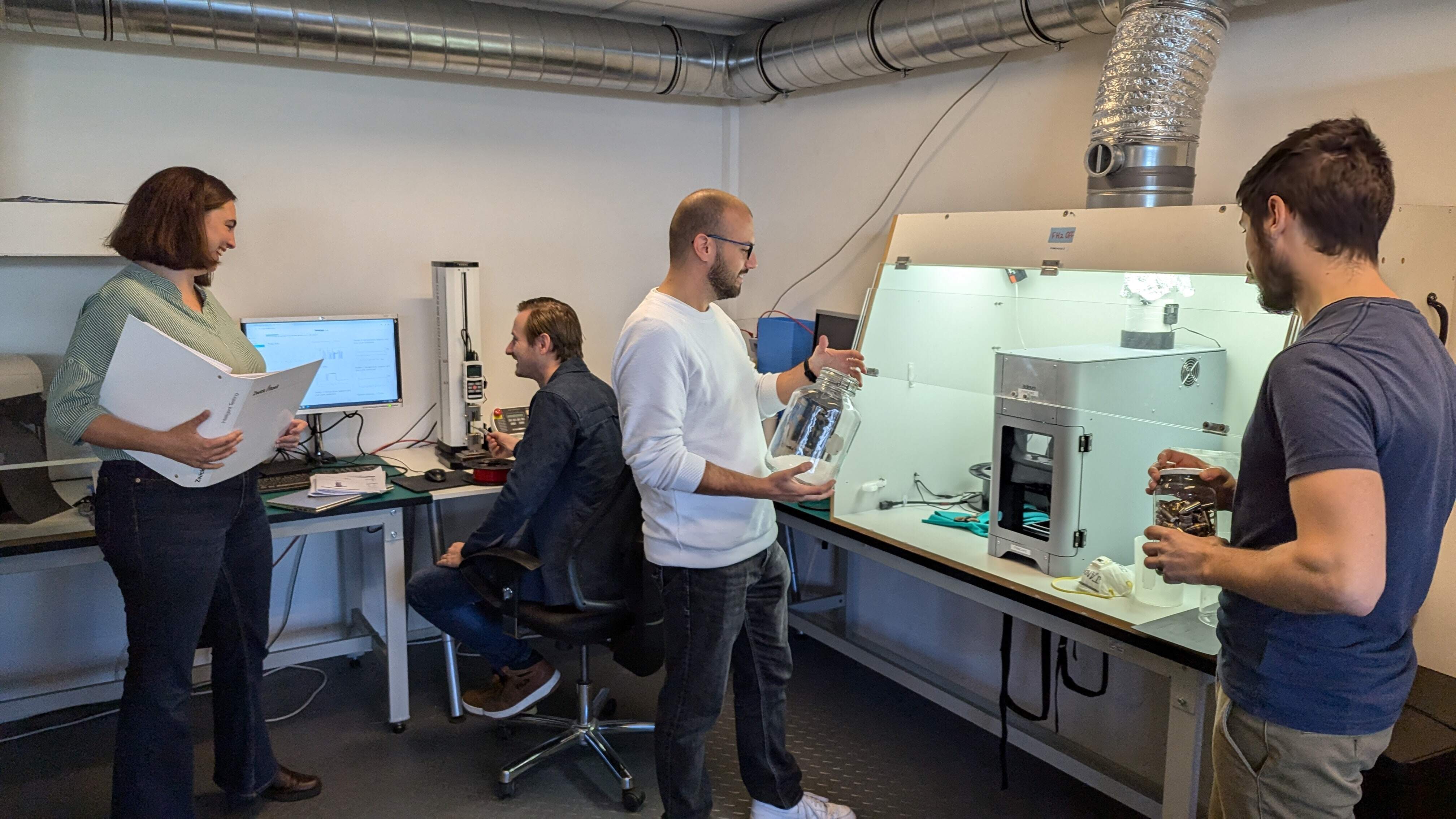

We all have to start somewhere. The beginnings of our Support Team start with a single engineer who spent as much time answering emails as they did building machines. Fast-forward a few years, and our "do-it-all" support style has transformed into a fully fledged Customer Success Team, specializing in everything from advanced material guidance to strategic project consulting.

This article walks through our journey from a scrappy startup team to a dedicated group of professionals that not only supports customers but partners with them to push the boundaries of 3D printing and recycling. Dive in to see how we went from handling hardware fixes to making innovation happen.

Beginnings / Flexibility

As a start-up, 3devo was a small company consisting of 8-10 people sharing all the excitement and responsibilities that the new business offered. The very people who designed and created the first iteration of our Filament Maker continued to focus on the machine even after the first product launched. Just like our engineers, our customers were eager to test the limits of our machine, while offering invaluable feedback on a regular basis.

"The know-hows of how polymers would behave inside our machine, what possible additives people could experiment with, how pre-processing might affect the final filament; there was a lot of research to be done. And so, the Material Specialist role was born."

Benjámin Beregszászi - Customer Support Agent at 3devo

This wasn’t always easy. Having a small team, limited resources, and being a fresh face in a rapidly growing industry came with challenges. Some of the first interns we had back then are still with us today as leading engineers in our large R&D department. These engineers were the first to answer customer enquiries, educating users as well as learning how best to improve our service approach.

This role suited our engineers as they already knew the Filament Maker inside out. Their communication elicited feedback that was the birth of our Support Platform. This feedback loop still exists today and is an integral part of our Success team, though in a much more expanded and comprehensive way (more on that later). For Service, repeat enquiries or issues prompted educational articles, instructional videos, or ideas for the future. Most importantly, it helped us make our product better by listening to our users’ first-hand experience and opinions. The resourcefulness and flexibility of 3devo employees in those early years set 3devo and its customers up for success through years to come.

However, soon it became obvious that fixing and improving the hardware is not the whole picture. Both internally in our company and externally with our customers, there was a need for additional knowledge regarding materials. The know-hows of how polymers would behave inside our machine, what possible additives people could experiment with, how pre-processing might affect the final filament; there was a lot of research to be done.

And so, the Materials Specialist role was born.

Full Timers / Dedication

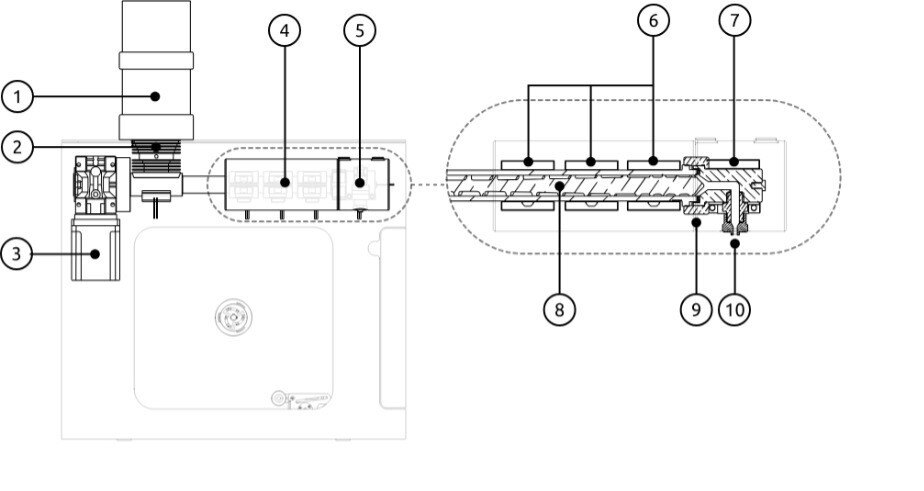

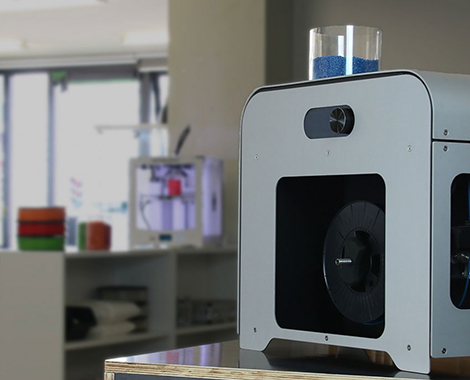

Though there were plenty of materials validated on the first Filament Maker before its completion, both we and our customers realized that this was just the tip of the iceberg. We needed to expand our knowledge and find the right people to do material research, as well as collect data from users. Furthermore, as the R&D department invested more time in developing and launching other products in the form of our first Shr3d It unit as well as the AirID Dryer, it was clear that Service needed dedicated personnel, too. This was, in essence, the start of the Customer Success Team.

We hired our first full-time employees with enough time and a surplus of ambition to carry out communications, troubleshooting, and the necessary research to help our clients. The first dedicated Support Agent worked and studied side by side with our R&D engineers to learn and document the increasing stock of machines, while the Material Specialists leaned into the material questions and investigated both issues and potentials. The feedback loop was still in place but was quickly diversified and optimized to track and manage a multitude of issues, questions, enquiries; all based on data and statistics that we’ve acquired over the first few years. From this we could expand our CRM and implement automation, refine our knowledge base, and create a channel of communication that is systematic and consistent.

There was also an increased collaboration emerging in 3devo between the R&D, Success, and Production departments. The inquiries and feedback received from users were fast-tracked to Production to spot quality issues, simplify operations, and accelerate repairs. Service, which was once a single engineer answering emails, evolved into Team Success: a functioning, interconnected and integral part of 3devo.

The combination of customer focused support and accumulated materials knowledge seeded a new idea in 3devo. Fundamentally, we wanted a closer connection with our client base. To better understand their contexts, limits, and aspirations, and how 3devo can best help with achieving their goals.

At this time, we did not fully know how to define or implement this perspective or make it realistic, however we did know that 3devo wanted to build its identity and business on one core tenet: enabling people to innovate their 3D printing projects.

The Team Grows / Expansion

To realize our ambition, we had to expand. 3devo hired a Service Specialist who, with an abundance of experience in strategic support and a penchant for structure, helped us take a step back and look at the bigger picture in terms of what service could be capable of. Up until this point every member of our Customer Success Team was actively engaging with customers in a highly personalized and tailored approach. As our brand and demand continued to grow, a new challenge emerged: how do we make our service scalable without sacrificing the attention to users’ needs? This balance of seamless automation with personalized communication is something we’re continuing to refine and tackle today.

During our scale up, we created additional Customer Support Agents who lent their own expertise in a variety of areas such as comprehensive information management, content writing, communications, copyediting, research skills and more. Our Support Platform ballooned with helpful articles and was optimized with refined search functions. At this point, we were really getting good at preventing issues before they have a chance to arise. Simply put, we reinforced our core priority in being proactive rather than reactive, when handling cases.

As the Service Team and overall hardware support advanced, it was the time for the Material Specialist role to make that same leap, and champion 3devo’s values in the newly devised Customer Success Manager role.

CSMs / Evolution

The Customer Success Manager (CSM) role could not exist without the Engineers, Support Agents, and Material Specialists that paved the way before. But it was obvious that as our client base grew, so did the complexity and diversity of their needs. We recognized that our Success Department had to adapt with specialized roles and structured processes that could scale alongside 3devo's growth.

Our CSMs, in particular, became integral to the Success Team, serving as both consultants and collaborators to customers experimenting with new and complex materials. These specialists expanded our material library and became trusted advisors, guiding users through the intricacies of filament extrusion and advising on custom setups for non-standard polymers. The knowledge they amassed also became a crucial resource for other teams within 3devo, feeding directly into R&D and shaping the enhancements to our Filament Maker and Shredder products.

Today, 3devo’s mission has evolved from merely providing hardware to actively and resolutely fostering partners’ projects. We began working more closely with clients to set up recycling programs, perform material feasibility tests, and consult on sustainability initiatives. The Success Team’s responsibilities expanded to include project management, guiding customers not only in using 3devo equipment but in achieving larger innovation goals with it. This transformation has allowed us to move beyond simply support and take on an active role as a valued partner in our customers’ success.

The Future

So, what’s next? It’s clear to us that the success of our company comes from the success of our partners. Looking ahead, we are aiming to scale up our Customer Success Team even more by creating more specialized roles to cover every one of our customer base’s needs. Naturally, with this we are committed to maintaining a balance between personalized support and scalability. This includes further training both internally and externally, expanding our knowledge base, enhancing our digital resources, and adopting new automation tools to handle routine queries while freeing our team to focus on complex, high-impact interactions.

Furthermore, as we establish ourselves as a reliable and knowledgeable voice in the 3D printing and filament extrusion industry, we are mindful of extending our reach and support to anyone interested in our services. We want to be just as valuable to the excitable student starting out their research, as we are to industry experts in the manufacturing and commercial market. And as we take pride in our trained and knowledgeable staff, we also commit to learning along the way and to never staying complacent in such a varied and fast-moving sector.

Discover our new Filament Maker TWO

Learn more about our new FM2 - a powerful filament extruder and filament research platform in one machine.

Frequently Asked Questions (FAQs)

Our Customer Success Team provides expert guidance on filament extrusion, including material compatibility, extrusion settings, and custom setups. We partner with clients to ensure optimal filament quality, troubleshooting any issues that arise.

Absolutely! We specialize in a number of project types, and one of those is supporting customers who want to recycle plastics into 3D printing filaments. Our team can guide you through every step, from shredding and processing plastic waste to creating new, functional filament.

3devo offers a comprehensive support platform with troubleshooting articles, instructional videos, and direct assistance from our Customer Success Team, helping you maintain smooth operation of your Filament Maker.

Our Materials Specialists are experienced in testing and developing custom materials for filament extrusion. They can advise on polymers, additives, and process adjustments, helping you experiment and create unique 3D printing materials.

Customer Success Managers at 3devo act as both consultants and collaborators. They provide specialized support for complex extrusion projects, advise on material selection, and help clients maximize the performance of their filament maker systems.

Yes, we work with universities, labs, and educational institutions to provide tailored support for filament extrusion and plastic recycling projects, offering insights and guidance to foster learning and innovation in 3D printing.

Begin Your Journey Towards Sustainable 3D Printing

Start by transforming plastic waste into recyclable material with our efficient and innovative shredder, designed to empower your filament recycling journey.

.jpg?width=865&height=500&name=GP20-Shredder-Hybrid-1%20(2).jpg)

Explore More on Sustainable 3D Printing Materials

Recycle Plastic Waste

Transform plastic waste into quality 3D printing filament and join our mission for responsible innovation with 3devo's complete recycling solution.

%20-%20instasize.png?width=800&height=640&name=which-plastics-are-recyclable%20(1)%20-%20instasize.png)

Which Plastics are recyclable?

Understand different plastic types and their recyclability to make informed decisions on selecting the right material for your needs.

%20-%20instasize%20(1).png?width=800&height=640&name=PETG-e1494958102567%20(1)%20-%20instasize%20(1).png)

How to recycle PET into Filament?

Discover how PET plastic is transformed into eco-friendly 3D printing filaments on our dedicated Recycling PET page.

Share this

- March 2025 (1)

- January 2025 (1)

- December 2024 (2)

- November 2024 (3)

- October 2024 (4)

- September 2024 (2)

- August 2024 (3)

- July 2024 (6)

- June 2024 (3)

- May 2024 (2)

- April 2024 (1)

- March 2024 (1)

- January 2024 (1)

- November 2023 (2)

- October 2023 (5)

- September 2023 (2)

- August 2023 (1)

- July 2023 (1)

- May 2023 (1)

- December 2022 (3)

- August 2022 (1)

- June 2022 (1)

- May 2022 (2)

- April 2022 (2)

- March 2022 (7)

- February 2022 (2)

- January 2022 (3)

- December 2021 (3)

- November 2021 (3)

- October 2021 (2)

- September 2021 (3)

- August 2021 (3)

- July 2021 (2)

- June 2021 (1)

- March 2021 (1)

- October 2020 (1)

- June 2020 (1)

- May 2020 (1)

- April 2020 (4)

- November 2019 (1)

- July 2019 (2)

- June 2019 (1)

- May 2019 (1)

- March 2019 (1)

- November 2018 (1)

- September 2018 (1)

- January 2018 (1)

- October 2017 (1)

- September 2017 (1)

- July 2017 (1)

- June 2017 (1)

- May 2017 (1)

- January 2017 (1)

- December 2016 (3)

- November 2016 (2)

- October 2016 (1)

- May 2016 (2)

- August 2015 (2)

- July 2015 (1)