Share this

3devo 2024 Highlights: Reflecting on a Year of Growth and Change

by Ellie Pritchard on Dec 18, 2024 9:48:36 AM

As 2024 comes to a close, we’re taking a moment to reflect on what has been one of the most exciting years in 3devo’s journey. This year was all about growth and change by stepping into new roles, even further embracing sustainability, and, most importantly, listening to our community of customers and partners.

From launching the Filament Maker TWO, our next generation filament extruder designed with your feedback at its heart, to redefining our approach with a partnership-focused business model, we’ve been working hard to stay ahead in the world of filament extrusion. We also took big steps towards sustainability with projects like AZ3D, transforming waste MJF powder into high quality FDM filament.

But 2024 wasn’t just about what we built; it was also about how we connected. Whether it was at Formnext, through collaborative projects, or through the machines you use every day, we’ve been proud to support your innovation. So... Let’s take a closer look at the milestones that made this year so memorable.

Embracing a New Business Model

If there’s one thing we’ve learned at 3devo, it’s that positive change thrives on collaboration. That’s why, in 2024, we decided to take a bold step forward, evolving from a company focused on selling machines to one that builds and nurtures true project partnerships.

This shift wasn’t just about business, rather it was about meeting the needs of our customers. We realized that whilst our machines such as the Filament Maker have been instrumental in advancing filament extrusion, customers needed more than just hardware. They needed guidance, expertise, and a partner who could help turn ideas into reality.

Our new approach means we’re with you at every stage of your journey, from initial set-up to project success. Here are some of the new ways in which we work together to help you get the most out of your filament extrusion process:

- Consulting: Whether you’re developing a new material or recycling waste, our team of Materials Experts is here to guide you.

- Material Testing: Do you have a great idea or complex material to extrude, but you're not yet sure if it would work? We’ll test it for you through one of our services!

- Co-Creation: If you are encountering specific limitations with your current project, we invite you to work with our R&D team to create the solution that’s tailored to your application.

By putting collaboration at the heart of what we do, we’re empowering you to push the boundaries of what’s possible in filament extrusion.

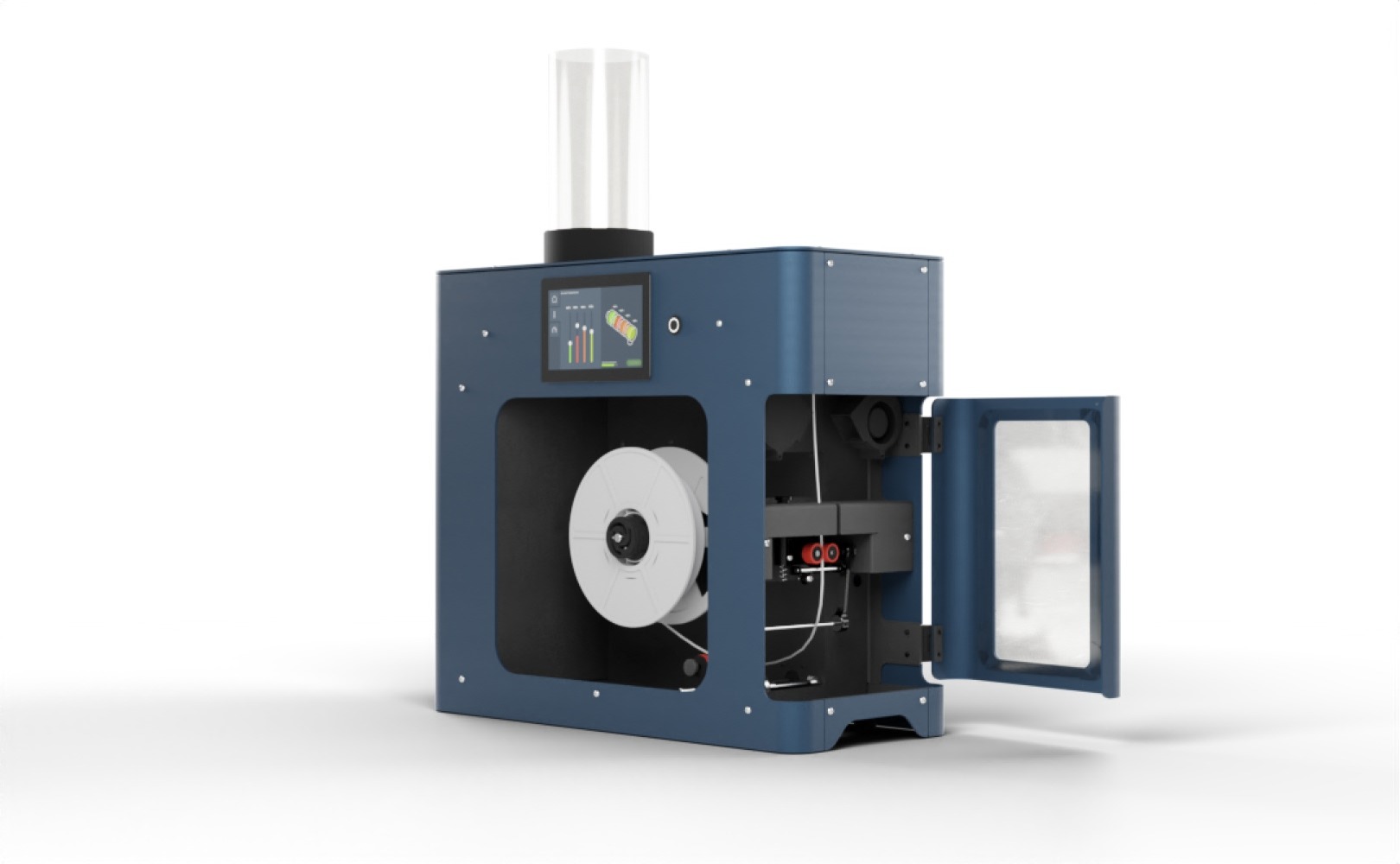

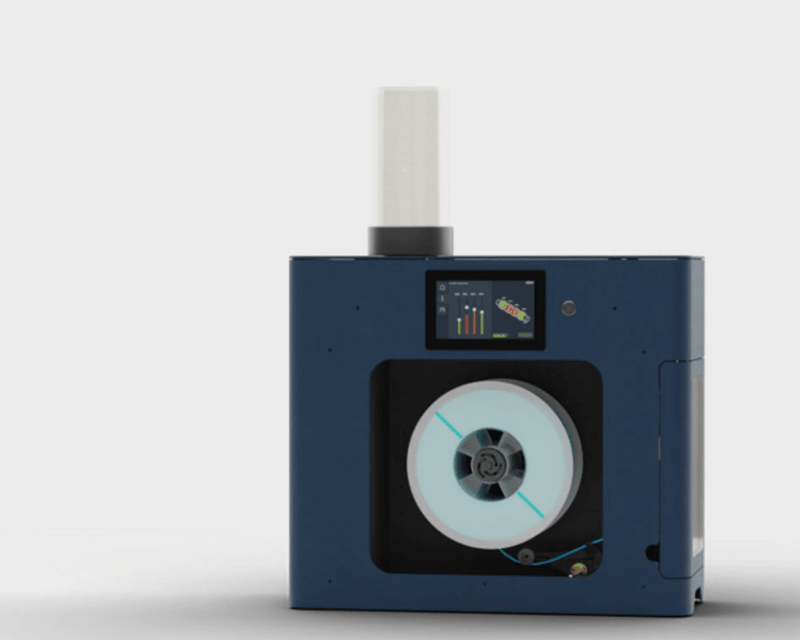

Filament Maker TWO – A Gamechanger!

When we started working on the development of our Filament Maker TWO, we knew we needed to learn from our most valuable resource: Our customers. Over the past two years, we have worked hard to implement the most impactful insights from users of our original Filament Maker ONE to create a machine that’s not only powerful but also incredibly intuitive.

The Filament Maker TWO represents everything we have learned. Here are some of the reasons why we are so excited about it:

- Longer Extruder Screw: The longer screw design aims for improved mixing and a more stable flow, enhancing your filament production.

- 3kg Spool Capacity: Longer runs naturally mean more filament, less downtime.

- Precision Monitoring: Advanced sensors track every stage of the extrusion process, ensuring the highest quality results.

We debuted the fully realized machine at Formnext 2024, and the response was overwhelming! Engineers, material specialists, and innovators from across the 3D printing industry got to see firsthand how this machine simplifies and elevates filament extrusion. If you haven’t checked it out yet, now’s the time to see what the future of filament-making looks like! And be sure to read up on the key features of the machine and how they came to be in this detailed blog.

Formnext 2024

Formnext 2024 wasn’t just another industry event for us, it was the perfect chance to showcase the full potential of our new direction. The energy and excitement at our booth were unforgettable, with hundreds of attendees stopping by to see our full plastic recycling process (including our GP20 Plastic Shredder and both Filament Makers ONE and TWO) in action!

Here are some of the highlights:

- Very First Filament Maker TWO Delivery: We were delighted that the whole 3devo team had the chance to see our first Filament Maker TWO changing hands and heading to a new home!

- Live Machine Demos: Attendees saw how our machines make filament extrusion stable and reliable, even with tricky materials.

- Connecting with Experts: From engineers to sustainability advocates, we had the chance to engage with industry leaders who share our vision for innovation and responsibility.

Formnext showed us that the work we’re doing resonates with people across the 3D printing world. It was a reminder that when you listen to your community, amazing things happen. For a full review of our Formnext 2024 experience, check out this blogpost!

Sustainability: AZ3D Project

One of the most exciting projects we tackled this year was with AZ3D, a prototype manufacturing company based in Arizona, US. During this collaboration, we aimed at solving a big problem in the 3D printing industry: what to do with waste MJF powder. The nylon-based powder is notoriously difficult to dispose of and cannot be used again in the MJF/SLS process. It is therefore often necessary for companies to store it in large quantities for years without a better solution. Instead of letting this material go to waste, we wanted to prove it could be transformed into something valuable, namely high-quality FDM filament.

Here’s how we made it happen:

After three years of research, AZ3D discovered 3devo. Unlike other companies, 3devo was willing to tackle the challenge of recycling MJF material. AZ3D sent a large sample of their waste to our facility in the Netherlands for testing. Through several phases of optimization, our Materials Specialist team successfully produced filament from the MJF material. From this, AZ3D was able to begin in-house production of 3D printing filament, capable of producing two spools per day with plenty of potential for increased output.

For us, this project wasn’t just about recycling (although that is one of our core focuses for our extrusion system), it’s about rethinking the way we use materials. By closing the loop and finding new life for waste, we’re taking steps toward a circular economy in 3D printing. And thanks to the Filament Maker TWO’s advanced capabilities, this process is more efficient and scalable than ever! We documented the story as a case study, available to read here!

The Impact of 2024: What It Means for the Future

Looking back, 2024 wasn’t just about launching new machines or showcasing cool projects, it was about building a foundation for the future. Every step we took this year was guided by our mission: to empower 3D printing innovators and make filament extrusion more accessible, sustainable, and impactful.

So what can you expect from us moving forward?

- Deeper Partnerships: We’re doubling down on collaboration, working hand-in-hand with customers and our wider industry network to achieve higher impact.

- More Sustainability Initiatives: Projects like AZ3D are just the beginning. We’re committed to finding new ways to reduce waste and create a greener future.

- Continued Innovation: The Filament Maker TWO was a milestone, but it’s not the end of the road. Our R&D team is ready to work with you to develop custom solutions to bring even more extrusion projects to success!

As we look ahead to 2025, we’re excited to keep growing with the industry around us. Thank you for being part of our journey - and here’s to another year of innovation!

Conclusion

From launching the Filament Maker TWO to expanding our collaborations and partnerships, 2024 has been all about pushing boundaries. We’ve grown, learned, and connected with so many of you along the way, and we couldn’t be more grateful.

As we move into 2025, we’re ready to take on new challenges and continue shaping the future of filament extrusion. Whether you’re an engineer, a researcher, or someone exploring new materials, we’re here to help you turn your ideas into reality.

Ready to take the next step in your filament-making journey? Reach out to us or check out our full plastic recycling solution to see how we can help.

Discover our new Filament Maker TWO

Learn more about our new Filament Maker TWO - a powerful filament extruder and filament research platform in one machine.

Share this

- March 2025 (1)

- January 2025 (1)

- December 2024 (2)

- November 2024 (3)

- October 2024 (4)

- September 2024 (2)

- August 2024 (3)

- July 2024 (6)

- June 2024 (3)

- May 2024 (2)

- April 2024 (1)

- March 2024 (1)

- January 2024 (1)

- November 2023 (2)

- October 2023 (5)

- September 2023 (2)

- August 2023 (1)

- July 2023 (1)

- May 2023 (1)

- December 2022 (3)

- August 2022 (1)

- June 2022 (1)

- May 2022 (2)

- April 2022 (2)

- March 2022 (7)

- February 2022 (2)

- January 2022 (3)

- December 2021 (3)

- November 2021 (3)

- October 2021 (2)

- September 2021 (3)

- August 2021 (3)

- July 2021 (2)

- June 2021 (1)

- March 2021 (1)

- October 2020 (1)

- June 2020 (1)

- May 2020 (1)

- April 2020 (4)

- November 2019 (1)

- July 2019 (2)

- June 2019 (1)

- May 2019 (1)

- March 2019 (1)

- November 2018 (1)

- September 2018 (1)

- January 2018 (1)

- October 2017 (1)

- September 2017 (1)

- July 2017 (1)

- June 2017 (1)

- May 2017 (1)

- January 2017 (1)

- December 2016 (3)

- November 2016 (2)

- October 2016 (1)

- May 2016 (2)

- August 2015 (2)

- July 2015 (1)