Introduction

Sustainable Solution for Classroom Waste

Spokane Public Schools District prides itself on its comprehensive engineering and computer science programs. One of the high schools - Ferris High School - led by its passionate engineering teacher, Gary Gillespie, sought to enhance its curriculum with practical, hands-on learning experiences. Despite having access to various 3D printing technologies, including Markforged and Flashforge printers, the school struggled to make the most of the material required for an entire student cohort to print with freedom.

Background

Mr Gillespie aimed to build a sustainable program that not only addressed waste management but also educated students on the importance of recycling and sustainable practices in engineering and manufacturing. In January 2024, Mr Gillespie rebranded the engineering department as Ferris Manufacturing, with its own website to showcase the students’ engineering projects.

The Challenge

Ferris High School, in Washington, USA, faced a significant challenge in managing and repurposing waste materials from their 3D printing projects. The school's limited budget compounded the need for innovative and sustainable solutions to minimize environmental impact and promote recycling among students.

When Gary Gillespie took on the role of Computer Science and Engineering teacher in 2022, he hoped to build a curriculum that placed the student at its center. “I wanted it to be student-driven to showcase what all of our students are capable of across the spectrum of engineering,” Mr Gillespie explains. “I’d love for them to have the mindset of seeing a manufacturing project all the way through, from concept to production.” 3devo is proud to offer a full recycling solution that makes this possible.

The Solution

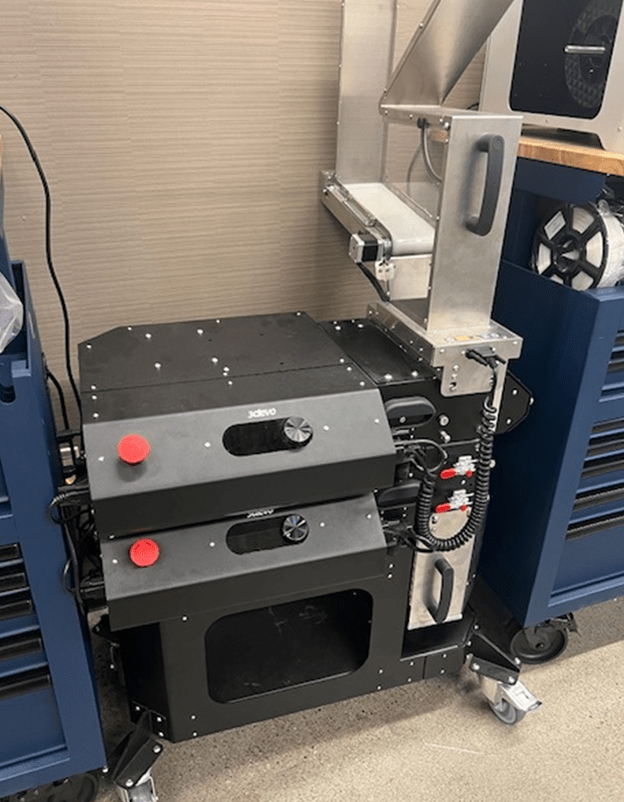

Mr Gillespie made the case to the Spokane Public Schools District Board to purchase a 3devo GP20 Plastic Shredder. One of the key advantages of this machine is its compartmentalized design, which enables easy part-repair and maintenance without needing to ship the entire unit away for servicing.

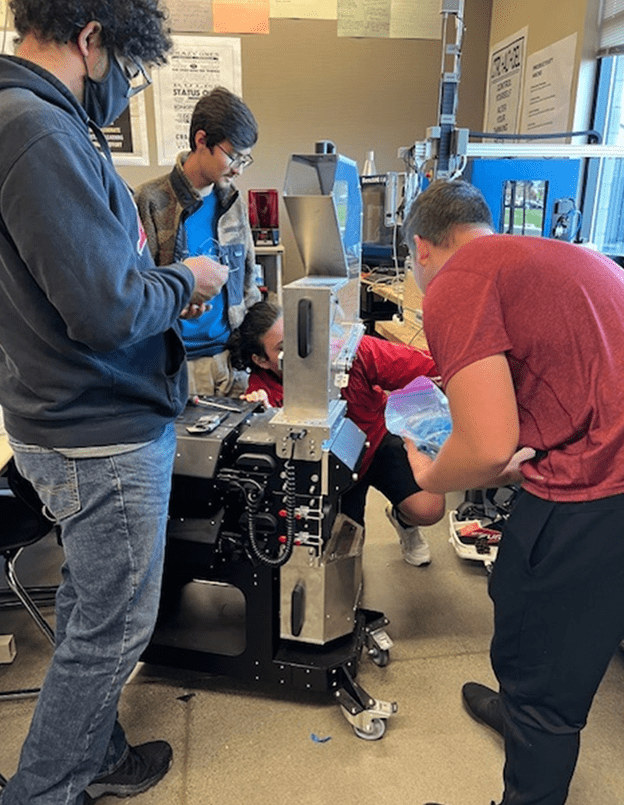

Mr Gillespie’s high school has now integrated the 3devo filament extruder and shredder into its curriculum. The Filament Maker and our Plastic Shredder have allowed the school to recycle used PLA and other 3D printing waste into new filament, enabling students to actively participate in the recycling process. Mr Gillespie wanted the students to be able to work with the machine in a hands-on way. “I want them to have the knowledge,” he explains. “I want them to be able to hit bumps in the road and figure out for themselves how to fix it, what that next step might be, rather than rely on me to solve things for them.”

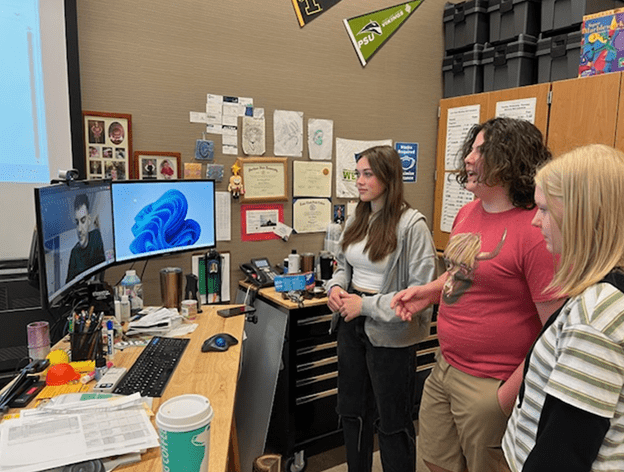

Our team provided extensive support, including guidance from our specialists and video meetings to ensure the smooth implementation of the new system. This collaboration was crucial in helping Mr Gillespie and his students to optimize their extrusion process and fully integrate the new equipment into their educational activities.

From the Ferris Manufacturing website: “We are one of only 4 high schools in the US that have this [3devo recycling] system. Now we can prototype all of our projects and not worry about wasted filament. Once done, prints can be put into the shredder and [granulator] to create extra small pieces. Then, these pieces will be placed into the [Filament Maker] and we can create new filament to be used again. Students have met twice with the 3Devo support team in the Netherlands.”

The enhanced productivity speaks volumes, as Mr Gillespie has been able to increase the number of projects from three per year to roughly three per week – a 3500% increase.

Get the Full

Spokane School District Customer Story

Spokane School District Customer Story

Workflow Highlights

The Next Generation of Sustainably-Minded Engineers

- Sustainable Practices:

The 3devo in-house filament extrusion system enabled the students to manage their 3D printing waste sustainably, significantly reducing their environmental impact. This system allowed the school to recycle used PLA into new filament, promoting a circular economy within their educational environment. - Educational Value:

Thanks to the user-friendly design of the machines, students are able to use the GP20 Shredder Granulator and Filament Maker with full autonomy – not only does this relieve some pressure from the educator, but also increases a sense of ownership for the students from a young age. Carrying this with them out of the classroom and into the early stages of their careers can only have a positive impact. The next generation of engineers, researchers, computer scientists, etc will feel accountable and responsible for the impact of their work and projects.

Ferris High School

More Success Stories

Lapland University

How Lapland University brings a sustainable closed-loop system within their 3D Printing Lab.

Sika Automotive

How Sika Automotive managed to reduce their production time – for their cavity sealers -from weeks to days.

Get the Full

Spokane School District Customer Story

Spokane School District Customer Story