Recycling Filament

Recycling plastic helps cut down on waste and keeps materials in use. It reduces pollution, saves energy, and keeps plastic out of landfills and oceans. It’s a simple way to make a positive impact on the environment and preserve resources.

Why Choose 3devo in Recycling?

Value out of Waste

Energy Efficient Recycling

Compact Size

5-Star Support

The Value of Recycled Filament

for Sustainable Innovation

Recycled filament is changing the game in 3D printing. By recycling PLA and other plastics, you can cut down on waste and still get top-quality materials for your projects. Whether you're reusing old prints or finding new ways to recycle, it’s a simple way to make a big impact on sustainability without sacrificing performance.

Create Value through Plastic Recycling

Recycle PLA and other thermoplastics to give your waste new life. It’s a straightforward way to cut down on excess materials, saving costs while keeping print quality high. Plus, reusing thermoplastics helps you streamline production and reduce waste at the same time.

Recycle 3D Prints for Responsible Innovation

Recycling 3D prints is about more than just sustainability—it’s about experimenting with fresh ideas. By reusing materials from past projects, you can test new concepts, refine your designs, and make your 3D printing process more flexible and inventive.

Boost Sustainability with Recycled Filament

Recycled filament from different plastics lets you maintain the quality of your prints while reducing your environmental impact. It’s a practical solution that keeps waste low without compromising on performance or the end result of your 3D printing projects.

Plastic Reclaimer

The GP20 Plastic Shredder is designed for efficient recycling of a wide range of thermoplastics, from standard materials like PLA and ABS to tougher polymers like PEEK. It turns waste into granulate, making it easy to reuse and recycle plastic in different projects.

Recycle 3D Prints for a Sustainable Workflow

Beyond just shredding, the GP20 Plastic Shredder plays a key role in creating a more sustainable production cycle. By turning used or failed prints into granulate, it helps reduce overall plastic waste and enables you to take control of your material consumption.

This shredding process supports an eco-conscious approach to 3D printing, giving you the flexibility to recycle and reuse plastics efficiently. Whether it's scraps from prototyping or end-of-life products, the GP20 makes it easy to integrate recycling into your workflow without sacrificing productivity.

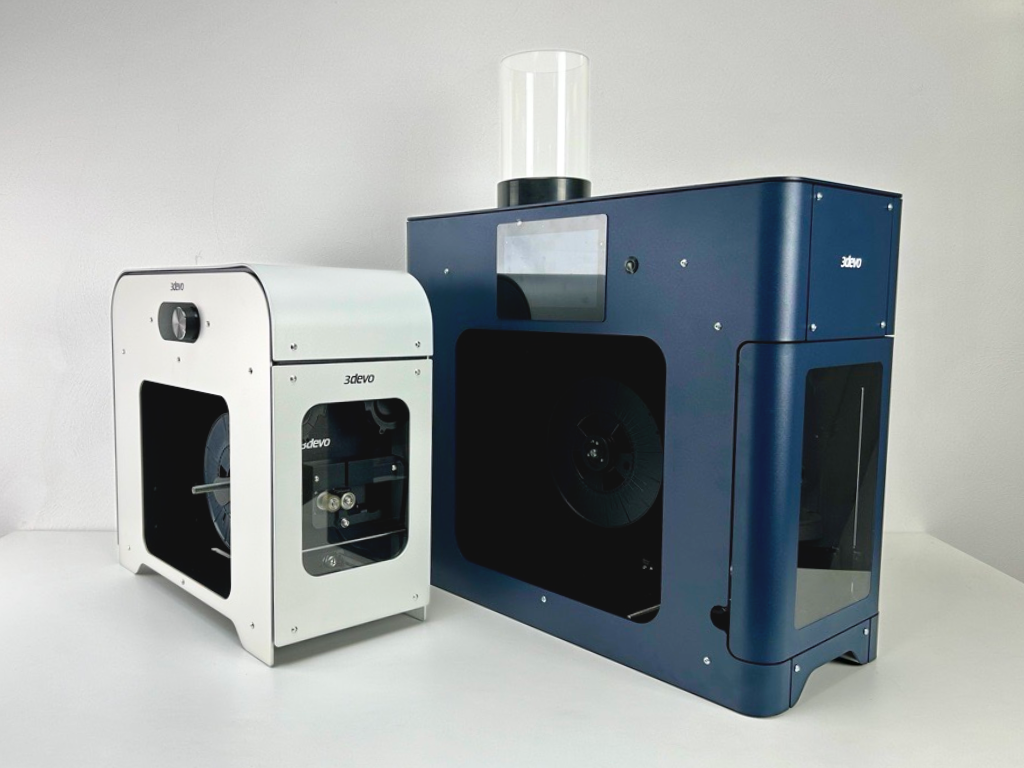

Filament Recycling with Filament Makers

The Filament Maker lets you recycle plastic waste into fresh filament, giving you control over your materials and reducing waste. It's a simple, effective way to turn discarded plastics into something usable for 3D printing.

Filament Recycling Service

The 3devo Filament Makers are designed to provide precision and flexibility for material extrusion. Whether you're recycling plastics or creating custom filaments from raw materials, these machines offer full control over temperature, extrusion speed, and filament quality.

With high-performance components and a user-friendly interface, they allow innovators to experiment with new materials or recycle waste into reliable filament. Their versatility makes them ideal for research, prototyping, and production, delivering consistent results for both professionals and enthusiasts in the 3D printing space.

Case Studies

Sustainability through recycling is the new reality for many businesses out there.

Check out how some of the biggest companies use 3devo's technology to achieve their goals.

Let's Talk About Your Project

Schedule a free online video consultation with one of our material specialists to discuss the details of your project.

Frequently Asked Questions

Yes, 3devo machines, such as the GP20 Plastic Shredder, can recycle PLA and a wide range of other thermoplastics. Once shredded, the plastic granulate can be fed into either the Filament Maker ONE or Filament Maker TWO to produce new filament, allowing you to reduce waste and repurpose materials efficiently.

The process begins with the 3devo's Plastic Reclaimer, which shreds plastics like PLA, ABS, and PEEK into granulate. This granulate is then used in the Filament Maker ONE or Filament Maker TWO to create fresh filament for new projects. This system allows you to recycle and reuse plastic waste, making the process more sustainable.

Yes, you can recycle different types of 3D prints, but it's best to process similar materials together. Recycling a mix of plastics, such as PLA and ABS, may affect the final filament quality. Sorting materials before recycling ensures a more reliable output and is highly recommended. For further help, you can reach out to our Customer Success team, who can guide you through the process.

A 3D filament recycling service helps reduce plastic waste and lower material costs while promoting sustainability in your 3D printing process. By recycling your used or failed prints, you minimize the need for new raw materials and make your production cycle more efficient. Additionally, our Customer Success Team is here to support you throughout the process, offering expert guidance to ensure you achieve the best results with your recycled materials. Whether you're new to recycling or looking to optimize your workflow, we’re here to help.

Leasing offers flexibility by allowing you to pay a monthly fee to use the machine, making it ideal for short-term projects or testing before committing to a full purchase. Buying, on the other hand, gives you ownership of the machine with a one-time investment. When leasing, you also get ongoing support from our materials experts, ensuring you have guidance in optimizing your processes and overcoming technical challenges.

Our new business model is centered around project partnerships, rather than just selling machines. We provide continuous support through our Customer Success and materials expert teams, helping you achieve your recycling and filament-making goals. This partnership ensures you get the most out of the machines while receiving expert guidance on material development, machine optimization, and process efficiency.

Yes, 3devo offers the option to upgrade from leasing to owning a machine. If you lease a machine and decide it's the right long-term solution for your projects, we’ll help you transition from a lease to full ownership. During the lease period, you'll also have full access to our material experts, who will help guide you through any challenges.