Share this

From PEEK to PEKK: The Ultimate Guide to High Performance Filaments

by Ellie Pritchard on Aug 30, 2024 10:06:30 AM

In the world of FDM 3D printing, the materials used can make all the difference. While standard plastic filaments like PLA and ABS have their place, there is a whole world of hardened and high-performance plastics that can take your projects to the next level. These advanced materials offer superior strength, durability, and resistance to extreme conditions, making them ideal for applications that demand more. At 3devo, we’re proud to support innovators in the 3D printing industry by providing the tools necessary to process such robust materials into custom filaments for their specific needs.

What Are Hardened and High-Performance Plastic Filaments?

Hardened and high-performance plastic filaments are engineered to withstand demanding environments, including high temperatures, chemical exposure, and mechanical stress.

For instance, Polycarbonate (PC) is widely used in the automotive and aerospace industries for parts that require high-impact resistance and thermal stability, such as headlight lenses, interior components, and structural parts. Polyetheretherketone (PEEK) is crucial in the medical field for surgical implants and aerospace engineering for high-performance components exposed to harsh environments. Nylon is often chosen for functional prototypes and end-use parts in the consumer goods and industrial sectors due to its balance of strength and flexibility. Meanwhile, Carbon Fiber Reinforced Polymers (CFRP) are incredibly useful in applications requiring lightweight yet incredibly strong materials, such as drone frames, automotive panels, and high-performance sporting equipment.

The Challenges of Processing High-Performance Filaments

Processing these advanced materials into filament isn’t as straightforward as working with standard plastics. High-performance filaments require precise temperature control, consistent extrusion rates, and sometimes even specialized equipment to handle the higher temperatures and more abrasive nature of these materials.

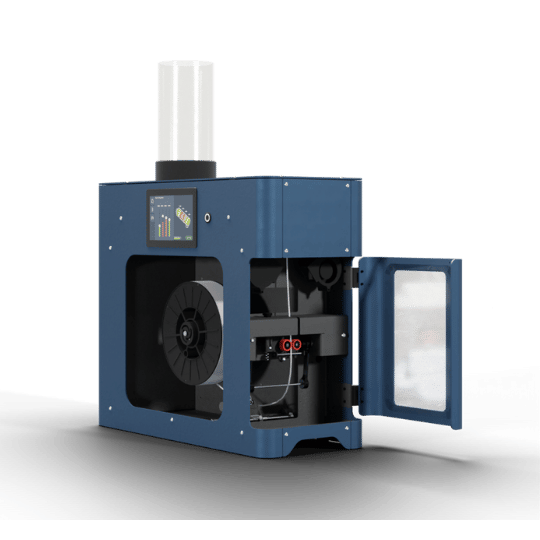

This is where a filament extruder comes into play. In particular, our 3devo Filament Makers are designed to handle a wide range of materials, including these hardened and high-performance plastics. With features like customizable temperature zones, adjustable screw speeds, and robust construction, our Filament Makers give users the flexibility and control needed to produce print-quality filament from even the most challenging materials.

Real-World Applications

Our customers have used our Filament Makers to create high-performance filaments for a variety of applications, from aerospace components to medical devices. These materials are not just about strength—they offer unique properties that can solve specific problems, such as chemical resistance in harsh environments or high thermal stability for parts exposed to extreme temperatures.

For example, a research team might develop a custom PEEK filament with enhanced properties for medical implants, or an automotive engineer could create a carbon fiber-reinforced filament for lightweight yet strong components.

How to Handle High-Performance Materials

High-performance plastic filaments offer unique properties that make them indispensable for cutting-edge applications across various industries. Below, we highlight some of these key materials, along with resources that dive deeper into their processing and applications.

Polycarbonate (PC)

Polycarbonate is a versatile thermoplastic known for its impressive impact resistance and ability to maintain structural integrity under high temperatures. It is frequently used in the production of automotive components, safety equipment, and electronic housings, where durability and thermal resilience are crucial.

- Explore Polycarbonate’s potential: Extruding Polycarbonate (PC) on the 3devo Advanced Desktop Filament Extruder

Polyetherketoneketone (PEKK)

PEKK is a member of the PAEK family (Polyaryletherketone) of semi-crystalline thermoplastics, renowned for its chemical resistance, mechanical strength, and high thermal performance. This material is often chosen for critical aerospace parts and medical devices, where exposure to harsh environments and stringent performance criteria are everyday challenges.

- Learn more about PEKK: All You Need to Know About PEKK

Polyetheretherketone (PEEK)

PEEK is one of the most sought-after high-performance thermoplastics, known for its exceptional strength and resistance to wear, heat, and chemicals. Its application ranges from aerospace components to medical implants, where the demands for reliability and performance are non-negotiable.

- Understand the standards for PEEK extrusion: Setting the Standard with PEEK – Advanced Level Desktop Extruder

- Learn about PEEK extrusion processes: PEEK Extrusion – A Guide to Processing This High-Performance Polymer

Carbon Fiber Reinforced Polymers (CFRP)

CFRP combines the strength and stiffness of carbon fiber with the versatility of thermoplastics, resulting in a material that is both lightweight and incredibly strong. This makes it ideal for applications in automotive and aerospace industries, where reducing weight without sacrificing strength is a priority.

- Dive into the world of Carbon Fiber filaments: Carbon Fiber Filament Guide

Sustainability and Recycling

As industries evolve, there is a growing emphasis on making manufacturing processes more sustainable. High-performance plastic filaments, known for their durability and advanced properties, also offer opportunities to reduce environmental impact. At 3devo, we like to focus on providing solutions that allow our customers to innovate responsibly, keeping efficiency and sustainability at the core of filament production.

High-performance materials like Polycarbonate (PC), PEEK, and Carbon Fiber Reinforced Polymers (CFRP) can be recycled, turning leftover scraps and failed prints into new filament. This approach reduces waste and maximizes the use of valuable resources. Alongside the Filament Makers, 3devo has also developed a powerful plastic shredder (GP20 Shredder) which can transform plastic of any shape and size into granulate-size material, ready to be processed. This enables users to recycle and re-extrude these materials into high-quality filament, not only minimizing waste but also making operations more resource-efficient.

Supporting Responsible Manufacturing

By choosing to recycle materials and minimize energy use in filament production, users contribute to a more sustainable approach to manufacturing. Whether you're developing lightweight components that reduce energy use in transportation or creating medical devices with extended lifespans, your work with high-performance filaments can align with broader goals of reducing environmental impact.

Using 3devo machines, customers can ensure that sustainability is integrated into their production process, providing not just high-performance results, but also responsible practices that resonate with today’s industry standards.

Learn more about our in-house plastic recycling solution here

How Filament Makers Empower Innovators

Whether a user is developing a new product, researching advanced materials, or looking to recycle thermoplastic waste into high-value filament, a filament maker such as that developed by 3devo can provide the capabilities they need.

Here are some examples of how a filament-making solution contributes to the 3D printing community:

- Custom Filament Production: Experiment with different material formulations to create custom filaments tailored to specific applications.

- Material Recycling: Convert thermoplastic waste into high-performance filament, contributing to sustainability while saving on material costs.

- Precision and Consistency: Achieve the exact specifications required for high-performance applications with precise control over the extrusion process.

Conclusion

The possibilities with hardened and high-performance filaments are vast. As 3D printing continues to grow in capability, the demand for advanced materials will only increase. At 3devo, we’re excited to be at the forefront of this innovation, providing the tools and expertise that innovators need to explore the full potential of these materials.

Whether you’re looking to push the boundaries of what’s possible with 3D printing or simply need reliable, high-quality filament, our filament makers are here to help you every step of the way.

Summary of High Performance Materials:

Polycarbonate (PC): Known for its impact resistance and high temperature tolerance, PC is used in industries like automotive, aerospace, and electronics.

Polyetheretherketone (PEEK): A high-performance thermoplastic, PEEK is incredibly strong and resistant to chemicals, making it suitable for medical implants, aerospace parts, and more.

Nylon: A versatile material with excellent durability and flexibility, Nylon is often used for functional parts that require a balance of strength and elasticity.

Carbon Fiber Reinforced Polymers (CFRP): These materials combine the lightweight properties of carbon fiber with the toughness of thermoplastics, creating filaments that are both strong and light.

Discover 3devo Filament Makers

Explore the full list of features available with our plastic filament extruders.

Frequently Asked Questions (FAQs)

Unlike standard filaments, high-performance filaments offer superior strength, durability, and resistance to harsh environments. While PLA and ABS are suitable for general-purpose 3D printing, high-performance filaments are designed for specialized applications where enhanced material properties are required.

Processing high-performance filaments requires precise temperature control, consistent extrusion rates, and sometimes specialized equipment. The higher processing temperatures and abrasive nature of these materials can be challenging without the right tools, which is where 3devo’s Filament Makers come into play.

Yes, 3devo Filament Makers are designed to process a wide range of materials, including high-performance plastics like Polycarbonate (PC), PEEK, PEKK, and Carbon Fiber Reinforced Polymers (CFRP). Our machines offer customizable settings that allow for precise control over the extrusion process, making them ideal for producing filaments from these advanced materials.

Recycling high-performance filaments involves reprocessing leftover material, failed prints, or even old products back into usable filament. 3devo’s machines are capable of handling the re-extrusion of these materials, enabling you to reduce waste and create new filaments from recycled material.

High-performance filaments are used in a variety of applications, including aerospace components that require high thermal stability, medical implants that demand biocompatibility and chemical resistance, and automotive parts that benefit from lightweight strength. These materials are chosen for their ability to meet the rigorous demands of these industries.

Share this

- March 2025 (1)

- January 2025 (1)

- December 2024 (2)

- November 2024 (3)

- October 2024 (4)

- September 2024 (2)

- August 2024 (3)

- July 2024 (6)

- June 2024 (3)

- May 2024 (2)

- April 2024 (1)

- March 2024 (1)

- January 2024 (1)

- November 2023 (2)

- October 2023 (5)

- September 2023 (2)

- August 2023 (1)

- July 2023 (1)

- May 2023 (1)

- December 2022 (3)

- August 2022 (1)

- June 2022 (1)

- May 2022 (2)

- April 2022 (2)

- March 2022 (7)

- February 2022 (2)

- January 2022 (3)

- December 2021 (3)

- November 2021 (3)

- October 2021 (2)

- September 2021 (3)

- August 2021 (3)

- July 2021 (2)

- June 2021 (1)

- March 2021 (1)

- October 2020 (1)

- June 2020 (1)

- May 2020 (1)

- April 2020 (4)

- November 2019 (1)

- July 2019 (2)

- June 2019 (1)

- May 2019 (1)

- March 2019 (1)

- November 2018 (1)

- September 2018 (1)

- January 2018 (1)

- October 2017 (1)

- September 2017 (1)

- July 2017 (1)

- June 2017 (1)

- May 2017 (1)

- January 2017 (1)

- December 2016 (3)

- November 2016 (2)

- October 2016 (1)

- May 2016 (2)

- August 2015 (2)

- July 2015 (1)