Share this

Which Plastics Are Recyclable?

by 3devo on Apr 16, 2020 3:02:00 PM

Did you know that less than 10% of the world’s plastic waste has been recycled? Despite increased awareness, much of our plastic waste ends up in landfills or oceans, harming wildlife and ecosystems. Understanding the recyclability of different polymers is a vital step toward tackling this growing issue.

With over 300 millions tons of plastic produced annually, understanding which plastics are recyclable and how to reduce plastic waste is essential for a sustainable future. In this blog post, we will explore the different types of plastics, how to recognize them, and the challenges associated with recycling.

In our previous blog post, we introduced you to our recycling journey and the mini-series we created for you on our YouTube channel. If you missed it, we recommend you check it out first before continuing on with this blog.

Which Plastics Are Recyclable and Which Are Not?

As you probably know, there are different types of plastic materials, and not all can be recycled. In this blog post, we are going to dive deeper into the different types that are out there and how you can recognize them.

It is also useful to know that, generally, plastics that are black in color or multilayered (as is often the case with plastic packaging) pose significant recycling challenges. These materials often require specialized sorting technologies, which may not be universally available. For example, black PET trays used in food packaging are difficult to detect in standard recycling systems, leading to increased plastic waste.

Types of Plastic

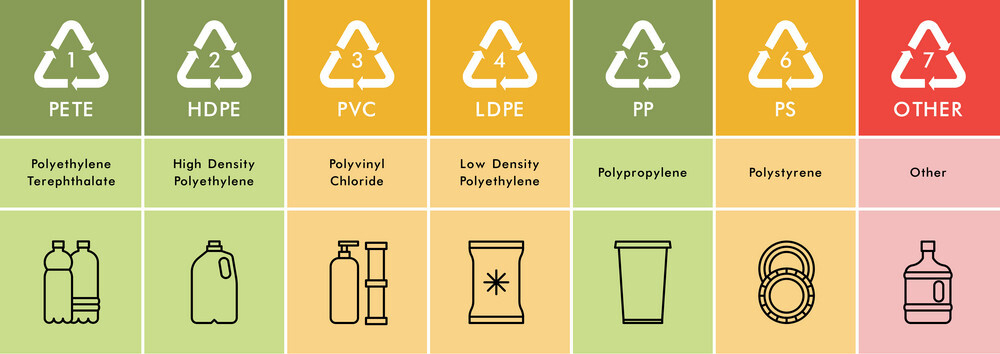

There are 7 types of plastic materials; PETE or PET, HDPE, V or PVC, LDPE, PP, PS, and Other / Miscellaneous Plastics. Let's take a closer look at each type:

For most plastic consumables, you can recognize the type of plastic used by an indented icon of each plastic code stated below.

1. PETE or PET – Polyethylene Terephthalate

PET is one of the most recyclable plastics and is often repurposed into polyester fibers or new containers. It’s used mostly in beverage bottles, detergent, and cleaning product bottles. It is also used for the finishing of objects such as liquid crystals, displays, carpets, clothes, guitars, and pianos. Therefore, this material is suitable for recycling into filament; however, it absorbs odors and flavors from foods and liquids stored in it, which can prevent you from being able to recycle PET into filament. Furthermore, the plastic is designed for blow-molding, not extrusion (it does not flow easily inside an extruder).

2. HDPE – High Density Polyethylene

Another common plastic material is HDPE, a versatile plastic type frequently found in household items and is highly recyclable. It is known for having a low risk of leaching into foods and or liquids. This material is mostly used in the making of children's toys, yogurt cups, milk jugs, shampoo bottles, and other similar products. Recycled HDPE is mostly turned into pens, plastic lumber, plastic fencing, picnic tables, and bottles. This material is suitable for recycling into filament, however, it can be a challenge; it flows easily but requires special cooling.

3. V or PVC – Polyvinyl Chloride

PVC plastics contain very harmful chemicals that have been linked to various diseases. This material is usually used for the making of plumbing pipes, tiles, windows, and medical equipment. Due to the fact that this material has harmful chemicals, it is not recommended to recycle it yourself. PVC only gets recycled by specialized programs that recycle it into flooring, paneling, and roadside gutters.

4. LDPE – Low-Density Polyethylene

This material is a very safe and clean plastic. It is recognized by its flexible and thin texture. It is commonly found in household items like grocery bags, plastic wraps, frozen food containers, and food-holding bottles. LDPE is recyclable but not recommended to recycle into filament due to its behavior in the molten state and the shape of the items it usually comes in (grocery bags being a good example of something painful to shred). Recycled LDPE is usually found back in garbage cans, paneling, furniture, flooring, and bubble wrap.

5. PP – Polypropylene

Another known safe plastic is PP. This material has a sturdy texture, and it is commonly found back in Tupperware, syrup bottles, medicine bottles, and yogurt containers. It is also heat resistant as it is also used in making microwavable food containers. PP is suitable for recycling into filament (depending on the item you want to recycle), and it is usually recycled into heavy-duty items like pallets, ice scrapers, rakes, and battery cables.

6. PS – Polystyrene

This material is your everyday plastic, found in beverage cups, plastic utensils, insulation, packing materials, egg cartons, and disposable dinnerware. Although some would say that it is notorious for leaching and poor recyclability, we actually managed to recycle it into filament. Polystyrene is the material we used in our recycling video, and therefore, we can recommend you recycle your PS objects into filament. However, it is a possibility that random PS items could react differently and, therefore, work differently as well,

7. Other / Miscellaneous Plastics

SPI 7 is seen as all kinds of plastic that do not fall in the 1 to 6 category. Miscellaneous plastics are usually found back in nylon, baby milk bottles, sunglasses, computer casings, and compact discs. This is actually the most important category since it contains all of the interesting plastics. All of the cool engineering and high-performance ones would correspond to 7. It consists of an immense variety (Nylon6 and other types of nylon, PEEK, PEKK, PEI, TPU, PC, and many more). This category is a lot harder to define, but there is a lot of potential.

The Challenges of Recycling Different Plastics

Recycling plastics comes with its set of challenges. For instance, plastics like PEEK, PET, etc., come in various grades, and not all can be easily extruded and printed. Additionally, parts made from commodity plastics (1 to 6, with a few in 7) are often originally injection-molded, which complicates their compatibility with extrusion recycling. However, regardless of the plastic type, the recycling methodology remains consistent, involving purity of the batch, shredding to an even size, and finding appropriate settings for successful extrusion.

Why is it Important to Recycle Plastics?

Recycling plastic is more than an environmental obligation; it's a pathway to conserving valuable resources and reducing pollution. Every ton of recycled plastic saves about 5,774 kWh of energy, 16.3 barrels of oil, and reduces greenhouse gas emissions equivalent to removing one car from the road for an entire year. Moreover, recycling reduces the demand for virgin plastic production, which consumes fossil fuels and releases harmful emissions. By embracing recycling practices and supporting innovations in polymer recycling technologies, we can significantly mitigate the plastic waste crisis while conserving energy and resources for future generations.

Next Steps: Shredding the Plastic Correctly for Extrusion

Having gained insight into different plastic types and their recycling challenges, our next focus is on shredding the plastic correctly to enable successful extrusion. Proper shredding ensures that plastic waste is broken down into uniform sizes, making the extrusion process more efficient and yielding higher-quality recycled materials. That step will be made more accessible with our GP20 Plastic Shredder.

Our Plastic Shredder is an innovative solution for plastic recycling, featuring an intelligent feeding system and interactive display for easy and efficient recycling of various plastic waste. Combining a smart plastic shredder with an integrated granulator, the GP20 Plastic Shredder simplifies the recycling process, making it accessible and convenient. With its user-friendly interface, automated settings, and enhanced safety features, this shredder empowers individuals and businesses to take charge of their recycling efforts, contributing to a greener and more sustainable future. Check it out here:

How 3devo is Closing the Loop on Plastic Recycling

At 3devo, we are bridging the gap between recycling and innovation by transforming discarded plastics into 3D printing filament. By combining our GP20 Shredder and Filament Maker, we enable users to take waste plastics like PET, HDPE, and PP and process them into high-quality, customizable filament for FDM 3D printing. This approach not only diverts plastic waste from landfills but also empowers innovators, researchers, and educators to experiment with recycled materials and reduce their reliance on virgin plastics. With every filament spool created from waste, we take a step closer to a circular economy where materials are reused, not discarded.

Conclusion

As we continue our recycling journey, it's crucial to understand the diversity of plastic materials and their recycling potential. By recognizing the different plastic types and their specific challenges, we can take informed steps towards a more sustainable future. Join us next week as we explore the art of shredding plastic for successful extrusion. Together, let's positively impact our environment by embracing the possibilities of plastic recycling.

Please remember to recycle responsibly and sort your collected plastic to facilitate the next steps of our recycling journey. Together, we can make a significant difference!

Additional Resources and Contact Information

If you are still left with some unanswered questions, we recommend you visit our webpage, which is dedicated to the polymer pyramid. You can also download all material guides in just one PDF file on that same webpage. It is also always possible to contact us and to speak with one of our material experts.

We hope to see you back next week. In the meantime, sort out your collected plastic so we can move on to the next step together!

Create Your Filament with Ease

Transform pellets or shredded plastic regrinds into custom 3D printing filaments right at your desk with our filament extruders. With industrial power and endless material possibilities, create, innovate, and 3D print like never before.

Frequently Asked Questions (FAQs)

Most recyclable plastics include PET (Polyethylene Terephthalate) and HDPE (High-Density Polyethylene), which are widely accepted by recycling programs due to their high demand and ease of processing. Other recyclable plastics include LDPE (Low-Density Polyethylene), PP (Polypropylene), and PS (Polystyrene), although their recyclability may depend on local facilities. To identify recyclable plastic types, look for recycling codes (1–7) imprinted on the plastic material.

Some types of plastic materials like PVC (Polyvinyl Chloride) and certain grades of plastic in the "Other" category (7) pose challenges due to harmful additives or multilayered structures.

PVC (Polyvinyl Chloride) is one of the most difficult plastics to recycle. While specialized programs recycle it into products like flooring, paneling, and gutters, it is not commonly accepted in household recycling streams due to its high chlorine content and toxic additives.

For those wondering, "what type of plastic is recyclable?", PVC ranks low in the list of recyclable plastic types due to these challenges. It's better to minimize PVC use when possible.

Yes, HDPE (High-Density Polyethylene) is highly recyclable and considered one of the most recyclable plastics. It is commonly used for products like milk jugs, shampoo bottles, and grocery bags. Recycled HDPE is often repurposed into new bottles, plastic lumber, fencing, and picnic tables.

When considering plastic recycling grades, HDPE belongs to grade 2, which is widely accepted by most recycling facilities. Its sturdy nature and low risk of leaching make it a valuable material in the types of plastic recycling.

Yes and it can be repurposed effectively into new materials. At 3devo, we work with innovators who want to transform LDPE waste, like plastic bags and shrink wrap, into 3D printing filament. Using tools like our shredder and filament maker, LDPE’s unique properties can be processed and reused efficiently. While traditional recycling programs may struggle with LDPE, solutions like ours make it possible to recycle and reuse this material sustainably.

Absolutely, PP is recyclable and holds great potential for reuse, but it often gets overlooked in traditional recycling streams due to its specific processing requirements. At 3devo, we've seen firsthand how versatile PP can be when given the chance to shine. With its high durability and resistance to wear, it’s a fantastic material to work with for 3D printing applications. By shredding PP waste, like food containers, bottle caps, and even old lab equipment, you can turn what might otherwise end up in the trash into functional, high-quality filament. It’s a perfect example of how innovation can close the loop on plastic waste.

- PET (Polyethylene Terephthalate)

- HDPE (High-Density Polyethylene)

- PVC (Polyvinyl Chloride)

- LDPE (Low-Density Polyethylene)

- PP (Polypropylene)

- PS (Polystyrene)

- Other / Miscellaneous Plastics (e.g., PEEK, PEI, and bioplastics)

Not all plastics are recyclable. Examples of what plastic is not recyclable include:

- Black plastics: Difficult to sort in standard recycling systems.

- Multilayered plastics: Found in food packaging, these are hard to separate and process.

- Contaminated plastics: Items with food residue or oil stains often cannot be recycled.

Certain types of recycled plastic, like PVC, require specialized programs due to their additives. Additionally, some grades of plastic under the "Other" category (7), such as thermosetting plastics, are non-recyclable because they cannot be remolded after curing.

Plastic grades are categorized based on their resin identification codes (1–7). These plastic recycling grades determine recyclability, uses, and material properties:

Grade 1 – PET: Easily recyclable, used for bottles and containers.

Grade 2 – HDPE: Highly recyclable, found in milk jugs and toys.

Grade 3 – PVC: Difficult to recycle, used in pipes and flooring.

Grade 4 – LDPE: Recyclable in some programs, used in plastic bags and wraps.

Grade 5 – PP: Recyclable, used in food containers and bottle caps.

Grade 6 – PS: Recyclable with limitations, found in disposable utensils and insulation.

Grade 7 – Other: Includes engineering plastics like PEEK, PEI, and TPU, which require specialized recycling.

Understanding these kinds of plastic and their recyclable plastic types is essential for responsible recycling efforts.

Share this

- November 2025 (1)

- October 2025 (1)

- March 2025 (1)

- January 2025 (1)

- December 2024 (2)

- November 2024 (2)

- October 2024 (4)

- September 2024 (2)

- August 2024 (3)

- July 2024 (6)

- June 2024 (3)

- May 2024 (2)

- April 2024 (1)

- March 2024 (1)

- January 2024 (1)

- November 2023 (2)

- October 2023 (5)

- September 2023 (2)

- August 2023 (1)

- July 2023 (1)

- May 2023 (1)

- December 2022 (2)

- June 2022 (1)

- May 2022 (2)

- April 2022 (2)

- March 2022 (6)

- February 2022 (2)

- January 2022 (3)

- December 2021 (3)

- November 2021 (3)

- October 2021 (2)

- September 2021 (3)

- August 2021 (3)

- July 2021 (2)

- June 2021 (1)

- March 2021 (1)

- October 2020 (1)

- June 2020 (1)

- May 2020 (1)

- April 2020 (4)

- November 2019 (1)

- July 2019 (2)

- June 2019 (1)

- May 2019 (1)

- March 2019 (1)

- November 2018 (1)

- September 2018 (1)

- January 2018 (1)

- October 2017 (1)

- September 2017 (1)

- July 2017 (1)

- June 2017 (1)

- May 2017 (1)

- January 2017 (1)

- December 2016 (3)

- November 2016 (2)

- October 2016 (1)

- May 2016 (2)

- August 2015 (2)

- July 2015 (1)