Share this

Sharing Plastics Knowledge and Engaging with Fellow Innovators

by 3devo on Oct 9, 2024 4:33:57 PM

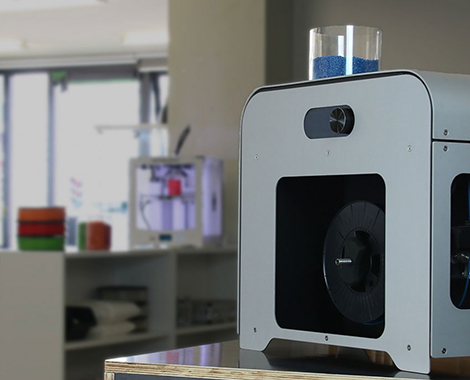

2024 has been a busy year for us at 3devo; not only have we taken bold steps to redefine our approach to plastic materials projects to ensure more impactful partnership, but we have also worked hard to spread the word about these changes. Positioning ourselves as materials experts in the world of plastic filament means sharing our knowledge and experiences with the 3D printing community – our machines (such as our Filament Makers and Plastic Shredder) enable success, but it is the expertise within our team that we value most.

We’d like to take a look at the opportunities to share our knowledge we have had so far, and those to look forward to.

TCT3SIXTY

Earlier this year, the 3devo team attended the 26th edition of the UK’s largest expo for the 3D printing industry. We traveled to Birmingham’s NEC event space to engage with the UK’s additive manufacturing community, to learn about the market-specific challenges faced by materials researchers and commercial entities alike, and discover exciting opportunities for our filament-making solutions. As well as our presence on the expo floor, we were also delighted to showcase our system via a presentation on the event’s Introducing Stage. Our Materials Specialist, Louis, presented our ambitious company goal of enabling 1 million 3D printing innovations by 2032 and explored the ways in which we hope to do this. Louis shared his thoughts on the experience: “I was thrilled to tell our story in person to a wider audience, including to curious spectators who hadn't heard of 3devo - nor even filament extrusion - before. I left with the impression that my message inspired at least a few innovators, and am now looking forward to the next wave of 3D printing innovation!”

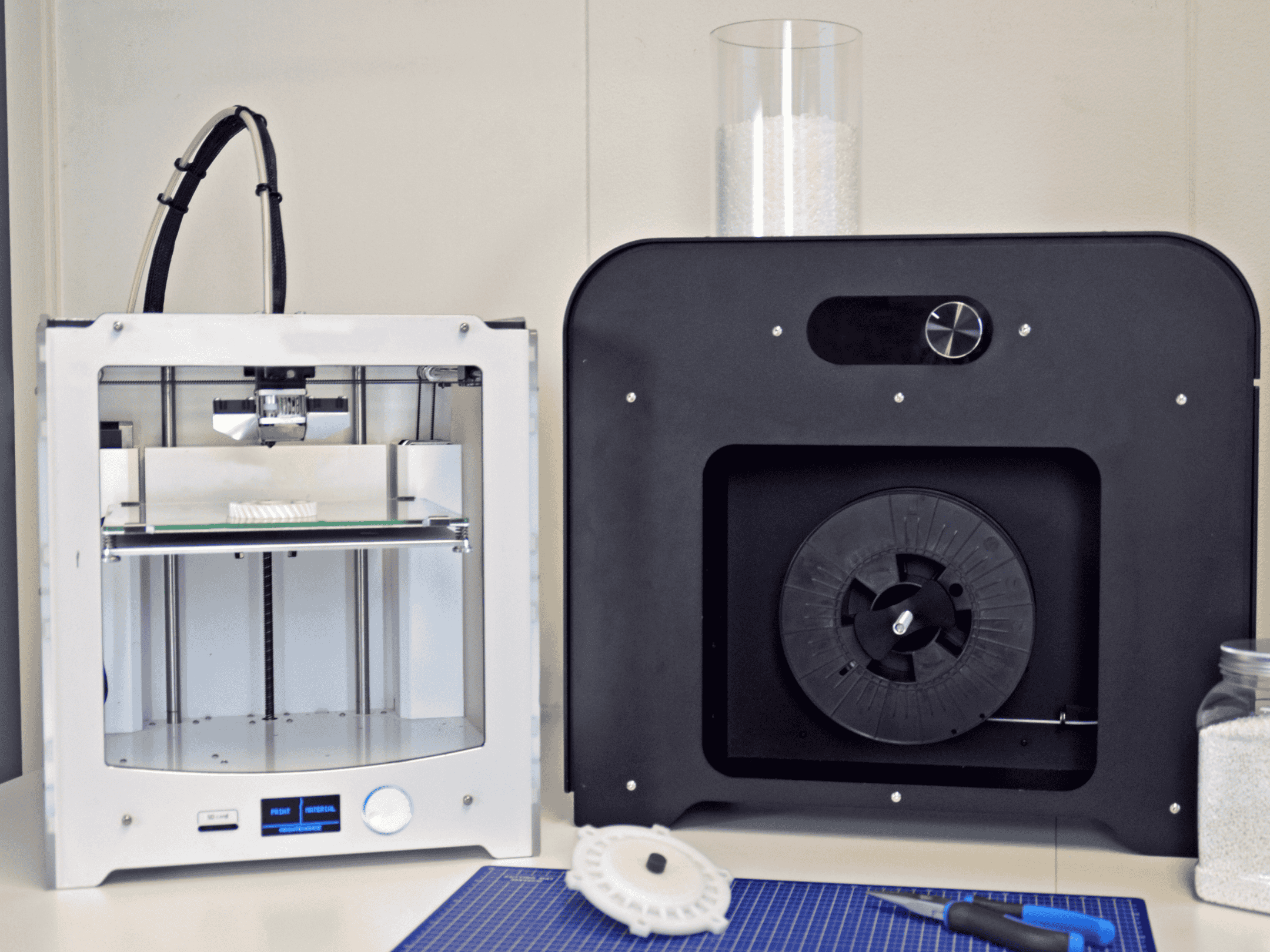

At TCT3SIXTY, our demo of both our Filament Makers ONE and TWO drew significant interest from companies and organizing exploring in-house recycling solutions. We had the opportunity to discuss with materials researchers and manufacturers about their needs for reducing waste in production.

HubSpot: Connect Amsterdam 2024

Bringing together a community of marketing, sales, and service professionals, software developer HubSpot hosted a day of keynotes and roundtable discussions to explore marketing trends, HubSpot insights and the evolving world of customer experience. Our very own Head of Support and Service, Jeroen, was invited to join a select panel of speakers to share his experience of using HubSpot services, and to gain insights for potential further implementation.

“I feel honored that I had the opportunity to share what Customer Success means to 3devo. As part of a customer panel of key users of the HubSpot CRM system: success is not measured by a closed deal, it is measured by the innovation driven from it. This new business model proves that the value of our product should grow with the cost over time, leading to recurring revenue and increased customer satisfaction. I am looking forward to see the results of this mindset and bring our research and innovation platform to the next level!”

Jeroen’s participation in the HubSpot panel was not only a chance to share our experiences but also a valuable opportunity to learn from other industry leaders. Key discussions on the evolving role of customer data in shaping better service experiences stood out. Inspired by these insights, we’re planning to refine our approach to customer support, leveraging HubSpot’s tools to build more personalized, data-driven service journeys for each of our clients. This will allow us to anticipate our customers’ needs and offer proactive solutions, fostering stronger, more meaningful partnerships.

3DNatives ADDITIV Polymer Virtual Event

At this moment, we are preparing for 3DNatives’ online ADDITIV Polymer event, a half day event on 10th October dedicated to exploring the role of polymers in additive manufacturing. Consisting of panels, workshops, and networking opportunities, ADDITIV Polymer provides a great platform for us at 3devo to share our materials knowledge whilst also broadening our vision for the future. Our Lead Materials Specialist, Timo, will be presenting a workshop looking at a key topic in the industry, shifting small- and large-scale mindset into seeing waste plastic as a valuable resource.

In particular, Timo will be exploring the ways in which our 3devo in-house plastic recycling technology can play a key role in closing the loop on plastic waste. By referring to customer case studies and real-world examples, he’ll explain how our combined GP20 Plastic Shredder and Filament Makers work together to transform failed prints, waste powder, and support materials into high quality FDM filament.

- The sustainability of 3D printing: 3D printing already reduces waste compared to conventional manufacturing, but there’s still room for improvement with leftover waste.

- Identifying the waste: We’ll dive into the specific types of waste—MJF, SLS, FDM—and the challenges they present, emphasizing the inevitability of waste in growing industries.

- The solution: We’ll then introduce 3devo’s in-house recycling technology as the key to closing this loop, transforming various types of waste (failed prints, powder, spools) into high-quality filament for reuse in FDM.

- Economic and environmental benefits: We will focus on the twofold impact: reduced environmental footprint and significant cost savings (e.g., recycling MJF/SLS waste), showing that waste can generate value.

- Real-world proof: We will demonstrate the impact of the recycling solution through real-world customer stories, such as our MJF powder project.

- Looking to the future: We’ll conclude by promoting the use of waste as a resource, contributing to the sustainability of the wider industry.

As polymers take center stage in the future of additive manufacturing, events like ADDITIV Polymer allow us to dive into critical discussions about waste reduction and sustainability. During Timo’s workshop, we’ll explore how 3devo’s machines are uniquely positioned to tackle these challenges. In particular, our recycling technology provides a practical solution for industries struggling with waste, enabling companies to create new filament from discarded materials. Those who join the online workshop can expect to leave with actionable insights on integrating sustainable practices into their workflow, inspired by real-world success stories.

Formnext 2024

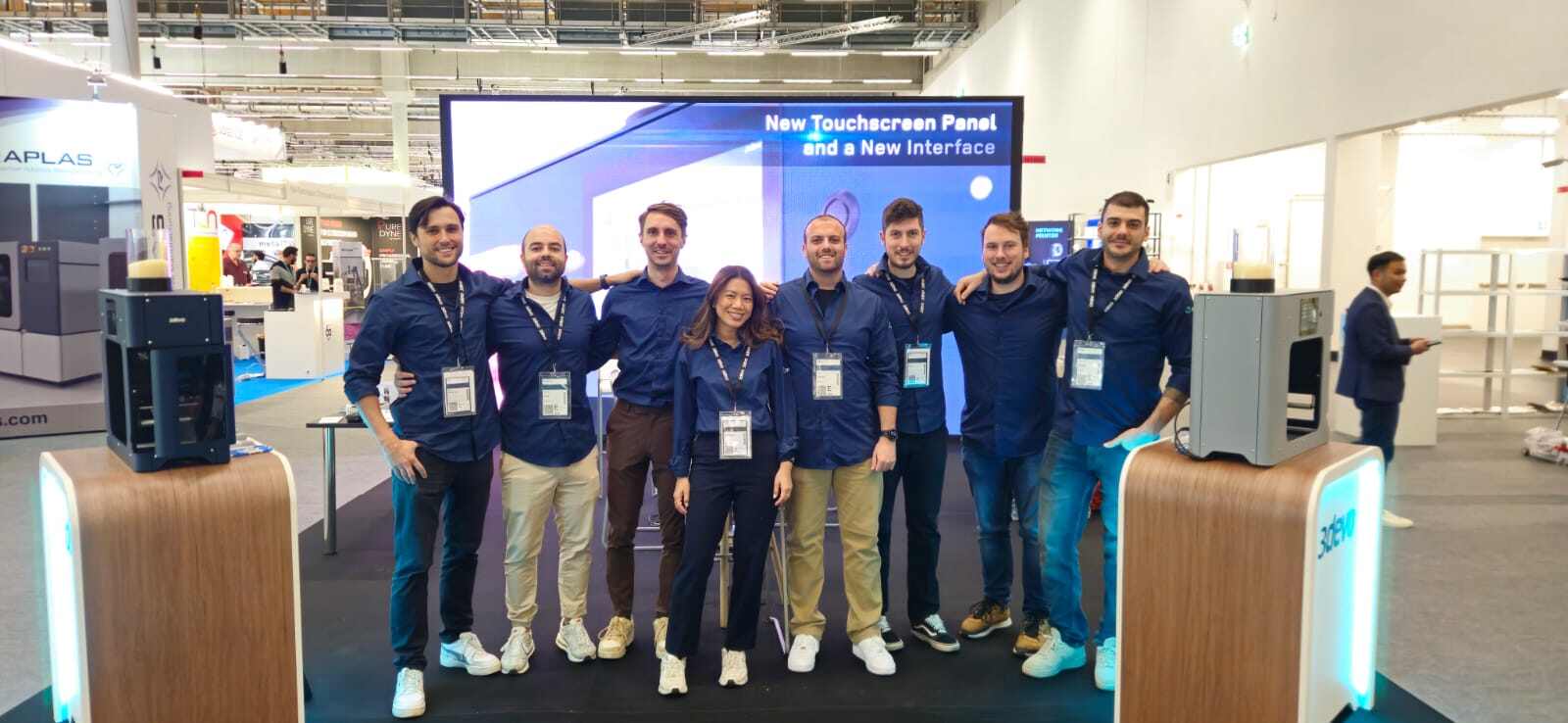

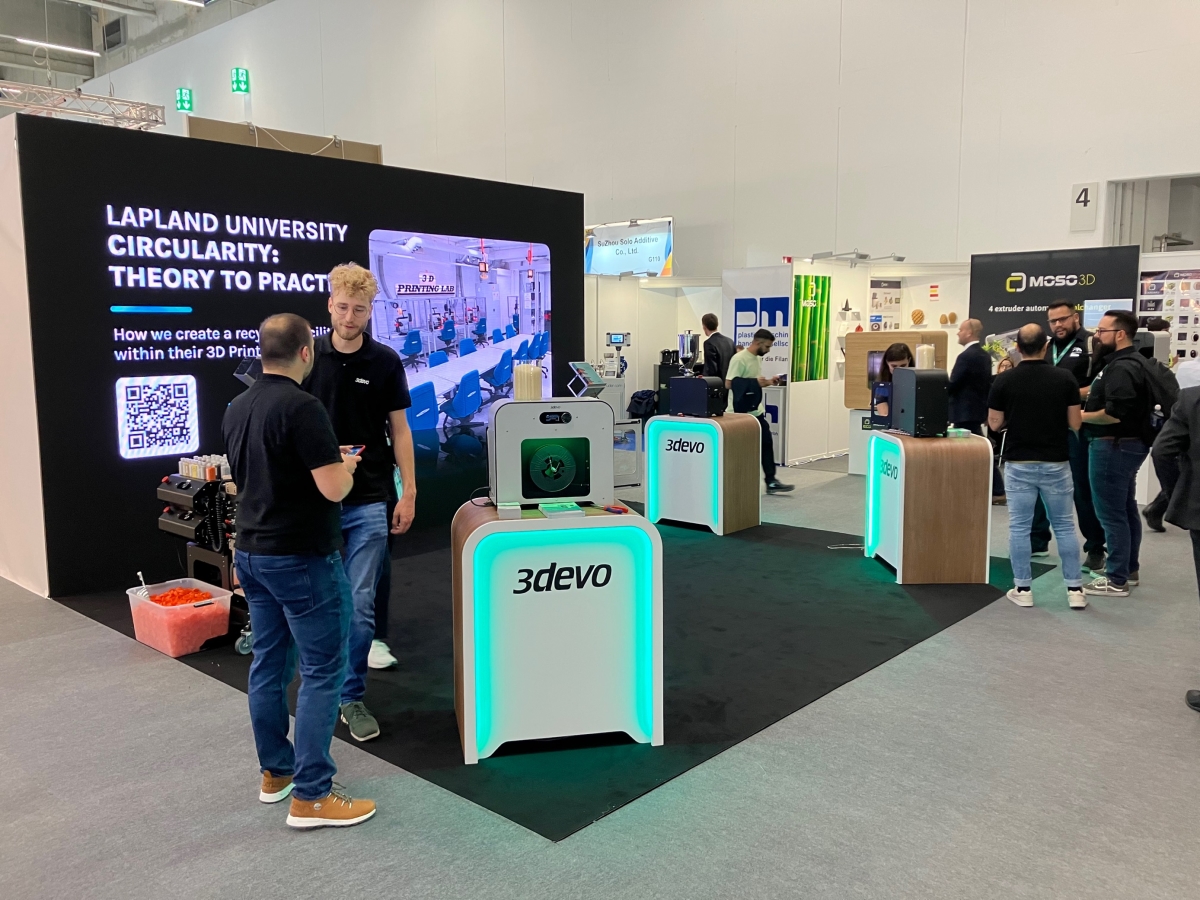

Of course, the biggest event in our calendar, and likely the same for the majority of those working in our industry, is Formnext. Hosted every November in Frankfurt, Germany, the expo is a central hub for 3D printing professionals ranging from production experts, to materials specialists, to solutions providers... and beyond!

Held this year between 19th-22nd November, the 3devo team will yet again be present to showcase the exciting updates to our offering and approach. Our focus will be divided into two key areas: one, the launch of our finalized Filament Maker TWO machine (initially introduced as an advanced prototype during the 2023 expo); and two, our updated approach to the way we work with our customers, through intentional project partnership to maximize success and meaningful results.

One of the key benefits of working with 3devo is the access to our in-house team of Materials Specialists. From the comfort of our Innovation Lab, our Materials Specialists work on validation services, such as MFIs (materials tests) and Filament Development Analyses, and conducting technical calls with customers – all in an effort to bring as many projects to successful completion as possible.

At Formnext, our full team of Materials Specialists will be present at our stand (F139 Hall 12.1) to answer your questions and discuss your project goals. They’ll be able to walk you through our project partnership approach, explain the filament-making process, and explore the best options for you and your application. We welcome all existing and prospective customers alike to visit our stand between 19th – 22nd November.

Conclusion

As we continue our journey through 2024, we remain committed to pushing the boundaries of what’s possible in the world of plastic filament and 3D printing. Each event we’ve participated in has provided valuable insights and opportunities to connect with forward-thinking professionals who share our vision of a more sustainable, innovative future. From TCT3SIXTY to Formnext, these gatherings allow us to not only showcase our technology but to learn, grow, and collaborate with others who are shaping the future of additive manufacturing.

Looking ahead, we’re excited to build on the knowledge and connections we’ve gained this year, with our evolving approach to customer partnerships, in-house expertise, and cutting-edge solutions leading the way. Whether we’re at an industry expo, delivering a workshop, or having a one-on-one conversation, we’re always ready to share our passion and expertise.

Discover our new Filament Maker TWO

Learn more about our new FM2 - a powerful filament extruder and filament research platform in one machine.

Frequently Asked Questions (FAQs)

Our focus in 2024 is to redefine our approach to plastic material projects and strengthen partnerships through collaboration and expertise. We’re committed to enabling innovations in 3D printing by offering advanced filament-making solutions while driving sustainability through recycling and waste reduction initiatives.

3devo helps address sustainability by offering in-house recycling solutions, such as our GP20 Plastic Shredder and Filament Makers, which transform waste materials (failed prints, support materials, powder) into high-quality filament. This reduces plastic waste and promotes a circular economy in the 3D printing industry.

Our in-house Materials Specialists provide personalized support, offering services such as materials validation tests (MFIs), technical consultations, and filament development analyses. By partnering with us, customers can maximize the success of their projects with expert guidance and tailored solutions.

You can see our machines in action at industry events like Formnext, where we offer live demos of our Filament Maker and Plastic Shredder. Additionally, we provide virtual demos and consultations for those who want to explore our solutions from anywhere in the world. Visit our website or contact us to schedule a session.

Begin Your Journey Towards Sustainable 3D Printing

Start by transforming plastic waste into recyclable material with our efficient and innovative shredder, designed to empower your filament recycling journey.

.jpg?width=865&height=500&name=GP20-Shredder-Hybrid-1%20(2).jpg)

Explore More on Sustainable 3D Printing Materials

Recycle Plastic Waste

Transform plastic waste into quality 3D printing filament and join our mission for responsible innovation with 3devo's complete recycling solution.

%20-%20instasize.png?width=800&height=640&name=which-plastics-are-recyclable%20(1)%20-%20instasize.png)

Which Plastics are recyclable?

Understand different plastic types and their recyclability to make informed decisions on selecting the right material for your needs.

%20-%20instasize%20(1).png?width=800&height=640&name=PETG-e1494958102567%20(1)%20-%20instasize%20(1).png)

How to recycle PET into Filament?

Discover how PET plastic is transformed into eco-friendly 3D printing filaments on our dedicated Recycling PET page.

Share this

- November 2025 (1)

- October 2025 (1)

- March 2025 (1)

- January 2025 (1)

- December 2024 (2)

- November 2024 (2)

- October 2024 (4)

- September 2024 (2)

- August 2024 (3)

- July 2024 (6)

- June 2024 (3)

- May 2024 (2)

- April 2024 (1)

- March 2024 (1)

- January 2024 (1)

- November 2023 (2)

- October 2023 (5)

- September 2023 (2)

- August 2023 (1)

- July 2023 (1)

- May 2023 (1)

- December 2022 (2)

- June 2022 (1)

- May 2022 (2)

- April 2022 (2)

- March 2022 (6)

- February 2022 (2)

- January 2022 (3)

- December 2021 (3)

- November 2021 (3)

- October 2021 (2)

- September 2021 (3)

- August 2021 (3)

- July 2021 (2)

- June 2021 (1)

- March 2021 (1)

- October 2020 (1)

- June 2020 (1)

- May 2020 (1)

- April 2020 (4)

- November 2019 (1)

- July 2019 (2)

- June 2019 (1)

- May 2019 (1)

- March 2019 (1)

- November 2018 (1)

- September 2018 (1)

- January 2018 (1)

- October 2017 (1)

- September 2017 (1)

- July 2017 (1)

- June 2017 (1)

- May 2017 (1)

- January 2017 (1)

- December 2016 (3)

- November 2016 (2)

- October 2016 (1)

- May 2016 (2)

- August 2015 (2)

- July 2015 (1)