Share this

The Complete Guide to Shredding Plastics

by 3devo on Apr 23, 2020 4:11:00 PM

Now that we have collected and separated our plastic waste, it is time to move on to the next step: Shredding the plastics… correctly. Now you may wonder, “how should you shred plastics?” and “what steps need to be considered?”. To answer your questions, we have created a seven-step guide for you in which we explain it all!

In our previous blog post, we reviewed the different types of recyclable plastics out there and how you can recognize them. If you missed it, we recommend you check that out before continuing with this blog, as it is a very important step to divide your plastics before shredding them.

Introduction

In the world of 3D printing, recycling and repurposing plastic waste is a crucial step toward sustainability. Once you've collected and separated your plastic waste, the next step is shredding the plastics correctly. But how should you shred plastics? What steps need to be considered? This article provides a comprehensive seven-step guide to shredding plastic waste for filament extrusion. Following these guidelines will help you achieve consistent regrinds, making the subsequent extrusion process seamless and efficient.

The 7 Step Guide To Shredding Plastics

There are several steps you need to take to be able to shred your plastic waste into consistent regrinds – which you can eventually extrude into filament. In the realm of filament making, recycling and repurposing plastic waste play a crucial role in sustainability. Before diving into filament extrusion, the initial step is shredding the plastics correctly.

1. Clean your plastic waste

Once you have sorted out your plastic waste and have separated them by each material type, it is of utmost importance to fully clean your plastic waste. You need to ensure your plastic waste is free from contaminants. For example, removing all the stickers, tags, dust, and liquids. Clean waste leads to better quality regrinds and prevents any issues during extrusion.

2. Store the plastic items

Once you have cleaned your plastic items, you need to make sure that they remain clean by storing them. When stored correctly, your plastics will not get dusty and will not get affected by any moisture.

3. Do not mix plastics

When shredding plastics, shredding different materials in one session is not recommended. Each material reacts differently to heat during the extrusion process, which will lead to inconsistencies in your filament. Some plastic might not even melt thoroughly, which could cause blockage in your extruder. Therefore, to avoid contamination, always shred each material separately.

4. Cut / break up the plastic items

As some plastic items are big, it is recommended to break them up into smaller pieces before feeding them into your shredder. Just like our material expert, Louis Rinaldo states in the video – “Always break larger plastics items into smaller parts before feeding the plastics into a plastic shredder“. By breaking them up into smaller pieces, you avoid overloading your shredder, which can cause malfunctions.

5. Feed the hopper

Now that you have broken up your plastic waste, you can feed them into the hopper of your shredder. Make sure to add your plastic waste in small batches so you do not overload the hopper.

6. Check your regrinds

Once you have grinned up your plastic waste, it is important to go through it and see if there are still some larger parts. Therefore, we recommend even re-shredding your regrinds so you can be sure that your shredded plastic batch is consistent throughout.

7. Store your regrinds

Just like we mentioned to store your plastic waste well in step 1, it is as important to store your regrind well too. Make sure that your regrinds are stored in a dust-free container and that no liquid can get to them, or else you will have polluted regrinds.

Conclusion

Shredding plastic waste is a crucial step in the process of 3D printing filament extrusion. By following the seven-step guide provided in this article, you can ensure that your regrinds are consistent and contamination-free. Properly cleaned and prepared plastic waste leads to high-quality filament, making your 3D printing projects more sustainable and cost-effective. Embrace the journey of recycling plastic waste.

Take Your Filament Production to the Next Level

Ready to unlock innovation and creativity in filament extrusion? Explore our complete filament production line packed into one powerful machine - the 3devo Filament Maker.

Elevate Your Recycling Game!

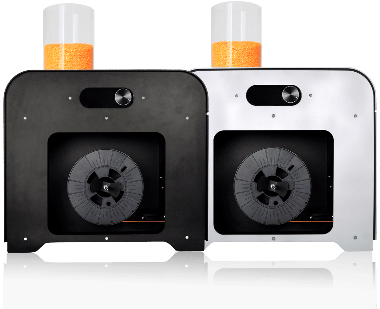

Ready to Revolutionize Recycling? Discover the GP20 Hybrid Shredder!

.png?width=1103&height=996&name=My%20project%20(1).png)

So now we have successfully shredded your plastic waste…what is next? Time to extrude your regrinds into filament! Eager to learn how? Keep an eye out for next week’s blog and video in which our material expert, Timo van der Laak will show you how to extrude.

If you are still left with some unanswered questions, feel free to contact us.

Until next week!

Share this

- March 2025 (1)

- January 2025 (1)

- December 2024 (2)

- November 2024 (3)

- October 2024 (4)

- September 2024 (2)

- August 2024 (3)

- July 2024 (6)

- June 2024 (3)

- May 2024 (2)

- April 2024 (1)

- March 2024 (1)

- January 2024 (1)

- November 2023 (2)

- October 2023 (5)

- September 2023 (2)

- August 2023 (1)

- July 2023 (1)

- May 2023 (1)

- December 2022 (3)

- August 2022 (1)

- June 2022 (1)

- May 2022 (2)

- April 2022 (2)

- March 2022 (7)

- February 2022 (2)

- January 2022 (3)

- December 2021 (3)

- November 2021 (3)

- October 2021 (2)

- September 2021 (3)

- August 2021 (3)

- July 2021 (2)

- June 2021 (1)

- March 2021 (1)

- October 2020 (1)

- June 2020 (1)

- May 2020 (1)

- April 2020 (4)

- November 2019 (1)

- July 2019 (2)

- June 2019 (1)

- May 2019 (1)

- March 2019 (1)

- November 2018 (1)

- September 2018 (1)

- January 2018 (1)

- October 2017 (1)

- September 2017 (1)

- July 2017 (1)

- June 2017 (1)

- May 2017 (1)

- January 2017 (1)

- December 2016 (3)

- November 2016 (2)

- October 2016 (1)

- May 2016 (2)

- August 2015 (2)

- July 2015 (1)