Share this

How Fontys University Uses Filament Maker for Hands-on Learning

by 3devo on Apr 21, 2022 10:15:00 AM

Proactive, future-oriented education that can contribute to a sustainable society has always been the goal for Fontys, one of the largest educational institutes in the Netherlands. This reflects in each of the university’s 200+ programs, which together account for an intake of over 44,000 students. The Natural Science wing of Fontys, located in Eindhoven, is one of the only institutes in the world to offer bachelor’s courses in polymer studies. Here, students use 3D printing to enhance polymers and develop sustainable solutions for the rapidly evolving additive manufacturing industry.

Training future polymer researchers

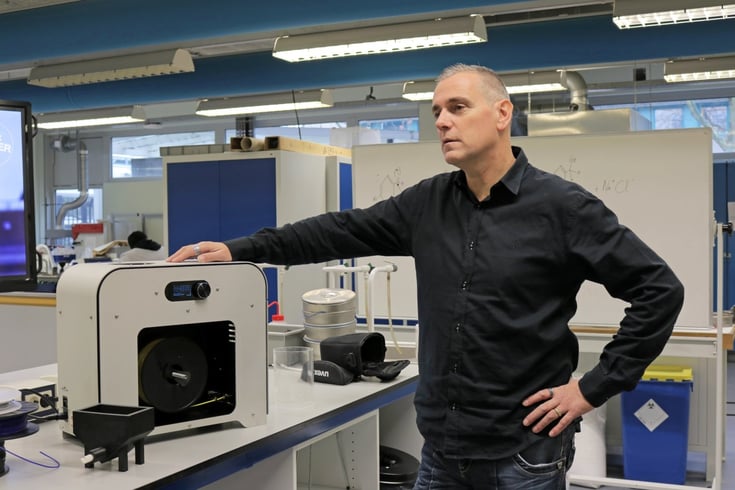

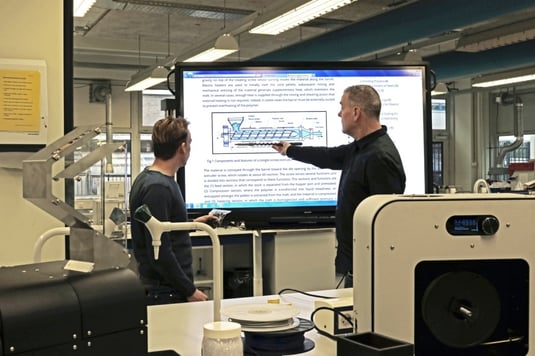

The polymer studies department at Fontys needed an accessible, user-friendly device that could thoroughly train students in material development and extrusion. Before purchasing the Filament Maker, the university had been relying on large-scale extrusion machinery, which did not provide much flexibility or support hands-on training. This typically resulted in a steep learning curve, not only for the students, but also for the faculty who would be training them. By extension, relying on industrial extrusion equipment led to a drain on the university’s time and resources. Guido Smets, project leader and researcher at Fontys emphasizes:

”We try to incorporate upcoming technologies such as 3D printing in our curriculum, studying it theoretically, and researching its applications. Our students use the Filament Maker to experiment with filament extrusion, exploring its applications in 3D printing and elsewhere.” - Guido Smets

Finding the ideal solution

It was at the 2016 edition of the Kunststoffen EXPO that the Fontys faculty first noticed 3devo's filament makers. As an extruder that could process small batches of filament, it promised them the flexibility to work with multiple polymers, as well as the ability to serve as an effective educational tool for the students. It could help polymer studies students in conducting research, without consuming too much time or material. In addition to this, adding a filament maker to the Fontys lab would also be significantly cheaper than continuing to depend on industrial extrusion equipment.

From Nano Tubes to Sustainable Polymers

The Composer 450 has been a core component of the polymer research facility at Fontys since December 2016. In less than a year’s time, it has significantly streamlined training and research, and has helped the university save time and money. Thanks to its small-scale processing ability, students can work with as little as 1kg of material at a time. They can also understand the process of extrusion in much more detail – something that complex extrusion machinery could not offer.

To date, over 20 students at Fontys have successfully polymer research projects using the filament maker. The simplicity and accessibility of the extruder has allowed them to fine-tune settings and get results in quick time. Some of the exciting projects that the filament maker has contributed to include studying the recyclability of PLA and PET, extruding custom materials for 3D printing nano tubes, and conducting tests on innovative polymer-cellulose composites.

Researchers and students at Fontys will use the Composer 450 to develop sustainable polymer-cellulose composites in the near future.

Our partnership

We are sure that this is only the beginning, and view the Fontys Case Study to see how the Composer 450 filament maker helped Fontys University go from strength to strength in the years to come.

Not only Fontys University made use of our products. Learn how Lapland University used polymers to create a circular environment in their 3D printing lab. Click the button below:

Share this

- March 2025 (1)

- January 2025 (1)

- December 2024 (2)

- November 2024 (3)

- October 2024 (4)

- September 2024 (2)

- August 2024 (3)

- July 2024 (6)

- June 2024 (3)

- May 2024 (2)

- April 2024 (1)

- March 2024 (1)

- January 2024 (1)

- November 2023 (2)

- October 2023 (5)

- September 2023 (2)

- August 2023 (1)

- July 2023 (1)

- May 2023 (1)

- December 2022 (3)

- August 2022 (1)

- June 2022 (1)

- May 2022 (2)

- April 2022 (2)

- March 2022 (7)

- February 2022 (2)

- January 2022 (3)

- December 2021 (3)

- November 2021 (3)

- October 2021 (2)

- September 2021 (3)

- August 2021 (3)

- July 2021 (2)

- June 2021 (1)

- March 2021 (1)

- October 2020 (1)

- June 2020 (1)

- May 2020 (1)

- April 2020 (4)

- November 2019 (1)

- July 2019 (2)

- June 2019 (1)

- May 2019 (1)

- March 2019 (1)

- November 2018 (1)

- September 2018 (1)

- January 2018 (1)

- October 2017 (1)

- September 2017 (1)

- July 2017 (1)

- June 2017 (1)

- May 2017 (1)

- January 2017 (1)

- December 2016 (3)

- November 2016 (2)

- October 2016 (1)

- May 2016 (2)

- August 2015 (2)

- July 2015 (1)