Share this

5 Plastic Recycling Solutions: Recycling for a Sustainable Future

by Ellie Pritchard on Sep 19, 2024 1:01:39 PM

As a worldwide issue, it is vital that the solution to the generation and mismanagement of plastic waste is also considered globally. At 3devo, we are proud to be part of a global movement, using our technology to enable in-house recycling for a range of users, from large production and manufacturing facilities to small-scale community programs, and thus contribute to a circular economy.

According to the research organization Earth Action, by the end of 2024 alone 220 million tons of plastic waste will have been created, with almost 70 million tons of this finding its way into the natural environment. Despite an increased awareness of its devastating impact in recent decades, Earth Action also reports that there has been more than a 7% increase in plastic waste. The scale of plastic waste is difficult to comprehend and correcting our global approach to its management can often feel like an insurmountable challenge to overcome.

At 3devo, we understand that our approach to plastic waste is small-scale in comparison to the overall problem – but a combined effort of many similar initiatives will contribute to a far greater impact. That is why we are proud to be a part of a wider structure, and we’d like to take the opportunity to shed light on similar organizations, companies, and initiatives developing impactful technologies in the fight against plastic waste.

So, let’s take a look at the some of these initiatives.

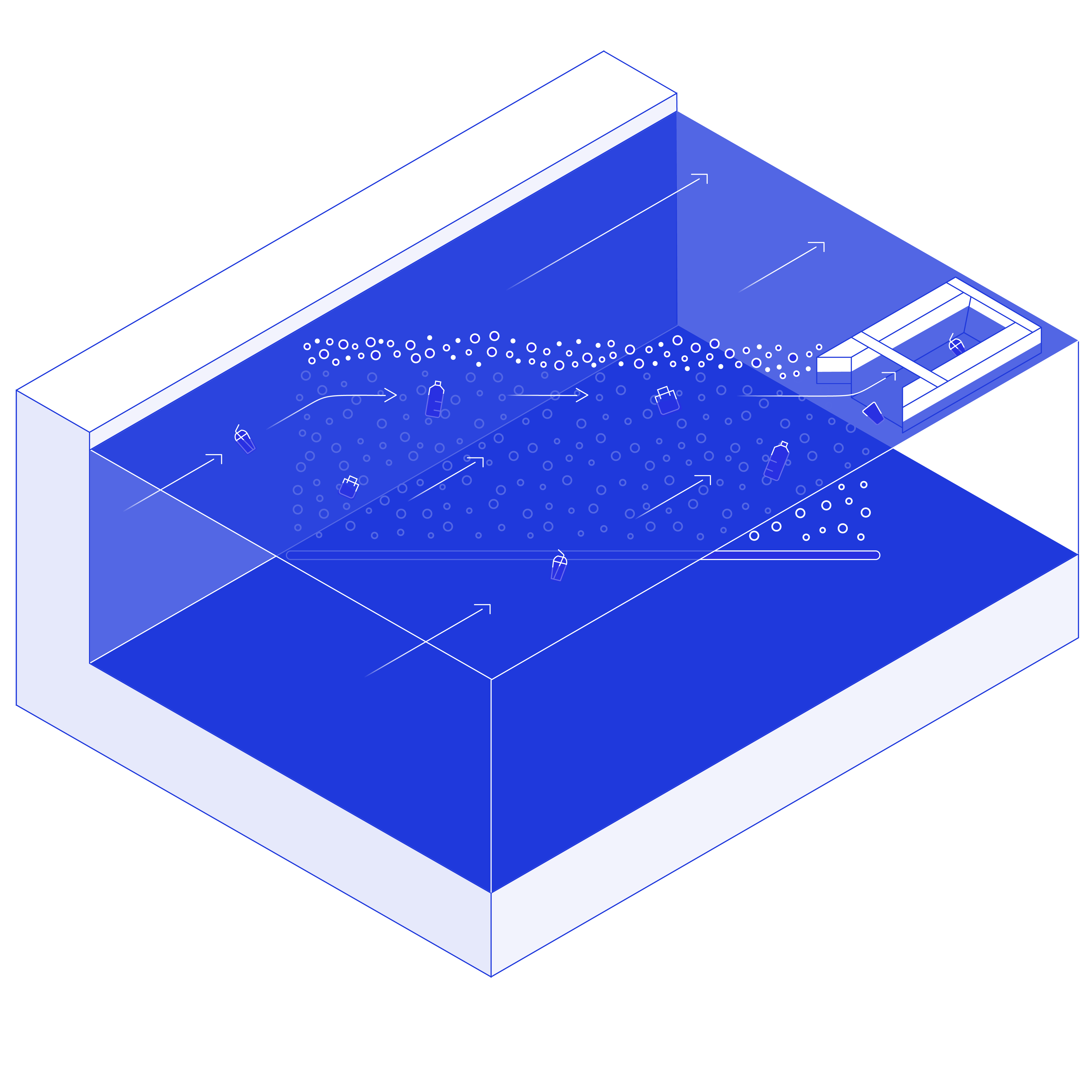

1. The Great Bubble Barrier

It is universal knowledge that a huge amount of plastic waste is entering our natural waterways, contaminating vulnerable environments and interfering with complex ecosystems. Earth Action reports that “Globally in 2024, a staggering 31.5% of plastic waste will be mismanaged at the end of its life, with the risk of this waste ending up in oceans.” In an effort to prevent such vast amounts of waste from entering the world’s oceans, Amsterdam-based start-up The Great Bubble Barrier has spent the past 7 years developing its non-invasive but highly effective bubble technology.

The bubble barrier is simple in its design, consisting of a perforated tube placed at the bottom of a waterway, which then pumps out air bubbles. This creates an upward current which directs plastic to the surface where it can be collected in a catchment system. Roughly 80kg of waste is collected by the Bubble Barrier Amsterdam each month, preventing that from entering the North Sea. The organization has now installed several barriers across the Netherlands (Katwijk, Wervershoof, Harlingen) and one in Portugal (Vila do Conde), with ambitions to grow further and clean waterways across the globe.

2. The Ocean Cleanup

Founded by Dutch inventor Boyan Slat, The Ocean Cleanup is at the forefront of large-scale efforts to rid the world’s oceans of plastic. The organization uses advanced technologies like floating barriers and autonomous systems to capture plastic waste in the world’s most polluted marine areas, such as the Great Pacific garbage patch. Their floating system, driven by ocean currents, passively collects plastic, allowing the team to remove it from the water without harming marine life.

Additionally, The Ocean Cleanup developed the Interceptor, a river cleanup solution that prevents plastic from reaching the ocean in the first place. This solar-powered, autonomous device is deployed in rivers around the globe, capturing waste before it spreads. The Ocean Cleanup’s goal is not only to remove existing plastic but also to address pollution at its source, creating a more sustainable and plastic-free future for the world's waterways.

3. Precious Plastic

Precious Plastic is a global movement dedicated to empowering individuals and communities to take control of plastic recycling. Founded by Dutch designer Dave Hakkens, the initiative provides open-source designs for simple, easy-to-build machines that allow anyone to recycle plastic waste and turn it into valuable new products. By decentralizing plastic recycling, Precious Plastic shifts the responsibility of tackling waste to local communities, allowing them to recycle on a small scale and foster creativity in product design.

From creating furniture to crafting everyday objects, people worldwide have embraced the Precious Plastic platform to reduce plastic waste in their neighborhoods. The organization also supports an active global community where members share ideas, tutorials, and products, making it a collaborative effort to combat plastic pollution. This grassroots approach promotes a circular economy, where waste is seen not as a burden but as a valuable resource that can be repurposed.

4. Polymateria

Polymateria is revolutionizing the way we think about plastic waste with its cutting-edge biotransformation technology. Based in the UK, the company has developed a proprietary solution that allows conventional plastic materials to break down in the natural environment within a defined timeframe, without leaving behind toxic residues or microplastics. Unlike traditional biodegradable plastics, which often require specific conditions like industrial composting, Polymateria's materials degrade in natural conditions, including landfills or open environments.

This innovative approach is a game-changer in addressing single-use plastics that often escape waste management systems and end up in nature. By creating plastics that can harmlessly return to the environment, Polymateria is helping industries move closer to a circular economy, reducing plastic waste while maintaining the functionality of everyday products. Their technology is especially valuable for items like packaging and consumer goods, where minimizing long-term environmental impact is critical.

5. 3devo

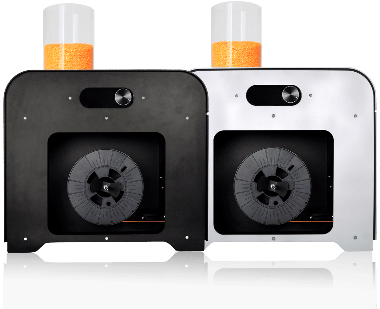

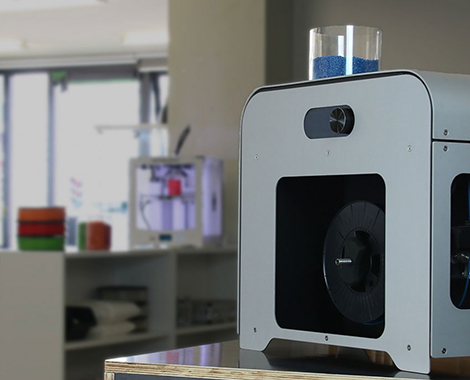

Based in the Netherlands, 3devo specializes in manufacturing professional-grade filament extrusion machines that allow users to recycle plastic waste into high-quality 3D printing filament. This innovation empowers businesses, educational institutions, and individuals to recycle their own plastic waste, reducing reliance on traditional waste management systems and creating new, sustainable uses for discarded materials.

3devo’s compact and user-friendly machines are designed to process various types of plastic waste, including household items and industrial scraps, into customizable filament for 3D printing. Their solution not only promotes local recycling but also helps companies reduce plastic consumption and waste production. By enabling users to turn waste into a resource, 3devo is playing a crucial role in addressing the global plastic waste crisis and fostering innovation in manufacturing and product design.

With their mission to make plastic recycling accessible and scalable, 3devo is helping bridge the gap between waste management and sustainable production, making it easier for industries and individuals to participate in the circular economy. Their technology supports a future where plastic waste is minimized, and materials can be endlessly reused in a closed-loop system.

Conclusion

Tackling the plastic waste crisis is one of the most complex and pressing challenges of our time, but it also serves as a catalyst for remarkable innovation. From ocean cleanup technologies to grassroots recycling movements, the organizations highlighted here demonstrate that impactful solutions can come from all corners of the world. These efforts, while diverse in approach, share a common goal: to address plastic pollution through sustainable, scalable innovation.

By turning waste into valuable resources, we believe that even small steps can create meaningful change. Together, through collaboration and innovative thinking, we can transform the way plastic waste is managed and work towards a more sustainable future for generations to come. This journey may be long, but it is one where every action counts, and we are excited to continue making an impact alongside these pioneers.

Transform Plastic Waste into Your Own Recycled Filament

Contribute to environmental sustainability, reduce waste, and unleash your creativity by transforming plastic waste into your own recycled filament.

Frequently Asked Questions (FAQs)

Recycling plastic into filament helps reduce the demand for virgin plastic production, which contributes significantly to environmental degradation. As discussed in the blog, by transforming plastic waste into reusable filament, you’re not only reducing plastic pollution but also extending the life cycle of materials that would otherwise end up in landfills.

The process begins with sorting and shredding plastic, followed by melting and extruding it into filament. This requires attention to material properties, such as melting temperature and durability. At 3devo, our team of Materials Specialists is able to draw from their wealth of materials knowledge and experience to assist you with all of your project needs.

Many common plastics, including PET, PLA, and ABS, can be recycled into 3D printing filaments. However, each plastic type has unique characteristics that influence how it needs to be processed. Some materials may require additional steps, like cleaning or drying, before they can be successfully recycled into high-quality filament.

Plastic waste accumulates in oceans and landfills, leading to long-term environmental damage. By recycling plastic into filament for 3D printing, individuals and industries can contribute to reducing the amount of waste generated. This approach turns waste into a valuable resource, supporting a more circular economy.

One challenge is ensuring that the plastic being recycled is free from contaminants and consistent in quality. It is important to acknowledge the complexities of handling different types of plastic, and these can affect the strength and usability of the recycled filament. Another challenge is controlling the properties of the final filament, such as flexibility and melting temperature, which vary based on the plastic used. That is why it is so valuable to have a team of experienced Materials Specialist to refer to in cases of complex materials or project-needs.

Absolutely, specialized equipment is essential for successfully recycling plastic waste into 3D printing filament. If you're in search of efficient and professional solutions for plastic shredding and filament making, we are pleased to introduce you to our GP20 Plastic Shredder and Filament Extruder.

Our GP20 Plastic Shredder is meticulously engineered to optimize the shredding process, transforming plastic waste into shreds suitable for filament extrusion. Simultaneously, our Filament Maker is designed to convert those shreds or plastic pellets into high-quality recycled filament. Both pieces of equipment are crafted with precision and innovation, making them indispensable tools for your journey toward creating recycled filament. With user-friendly features and robust performance, they ensure your plastic waste is effectively processed and converted into recycled filament, a topic we've extensively covered in this blog.

As you embark on your sustainable 3D printing adventure, our GP20 Plastic Shredder and Filament Maker stand as testaments to our commitment to empowering individuals and businesses with the tools necessary to positively impact the environment. Discover how this innovative duo can revolutionize your approach to filament recycling and enhance your contribution to a greener future.

Innovation in 3D printing and plastic recycling is crucial for minimizing plastic waste. In the blog, we explored how emerging technologies enable more efficient recycling and reuse of plastics. As these technologies improve, they offer new ways to handle waste, allowing more people and companies to participate in sustainable practices through 3D printing.

Begin Your Journey Towards Sustainable 3D Printing

Start by transforming plastic waste into recyclable material with our efficient and innovative shredder, designed to empower your filament recycling journey.

.jpg?width=865&height=500&name=GP20-Shredder-Hybrid-1%20(2).jpg)

Explore More on Sustainable 3D Printing Materials

Recycle Plastic Waste

Transform plastic waste into quality 3D printing filament and join our mission for responsible innovation with 3devo's complete recycling solution.

%20-%20instasize.png?width=800&height=640&name=which-plastics-are-recyclable%20(1)%20-%20instasize.png)

Which Plastics are recyclable?

Understand different plastic types and their recyclability to make informed decisions on selecting the right material for your needs.

%20-%20instasize%20(1).png?width=800&height=640&name=PETG-e1494958102567%20(1)%20-%20instasize%20(1).png)

How to recycle PET into Filament?

Discover how PET plastic is transformed into eco-friendly 3D printing filaments on our dedicated Recycling PET page.

Share this

- March 2025 (1)

- January 2025 (1)

- December 2024 (2)

- November 2024 (3)

- October 2024 (4)

- September 2024 (2)

- August 2024 (3)

- July 2024 (6)

- June 2024 (3)

- May 2024 (2)

- April 2024 (1)

- March 2024 (1)

- January 2024 (1)

- November 2023 (2)

- October 2023 (5)

- September 2023 (2)

- August 2023 (1)

- July 2023 (1)

- May 2023 (1)

- December 2022 (3)

- August 2022 (1)

- June 2022 (1)

- May 2022 (2)

- April 2022 (2)

- March 2022 (7)

- February 2022 (2)

- January 2022 (3)

- December 2021 (3)

- November 2021 (3)

- October 2021 (2)

- September 2021 (3)

- August 2021 (3)

- July 2021 (2)

- June 2021 (1)

- March 2021 (1)

- October 2020 (1)

- June 2020 (1)

- May 2020 (1)

- April 2020 (4)

- November 2019 (1)

- July 2019 (2)

- June 2019 (1)

- May 2019 (1)

- March 2019 (1)

- November 2018 (1)

- September 2018 (1)

- January 2018 (1)

- October 2017 (1)

- September 2017 (1)

- July 2017 (1)

- June 2017 (1)

- May 2017 (1)

- January 2017 (1)

- December 2016 (3)

- November 2016 (2)

- October 2016 (1)

- May 2016 (2)

- August 2015 (2)

- July 2015 (1)