Research EngineersWe could be your new research partner

Feel empowered with project validation, rapid prototyping, and flexible support

Trusted By the Best Researchers and Engineers:

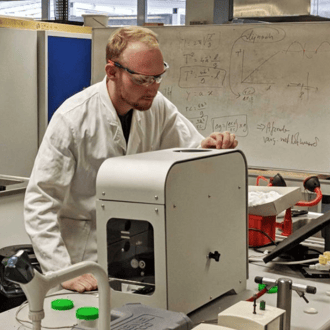

At 3devo, we know only too well that Research Engineers in the 3D printing industry face the constant challenge of not just keeping pace, but staying ahead. Rapid prototyping and validation are critical, especially when it comes to transforming new materials and compounds into viable 3D printing filament.

Challenges & Solutions

At a Glance

Industrial Quality

After Sales Support

Easy Maintenance

No Set Up Needed

Onboarding

Project Viability

Pain Point: Uncertainty over project success and likelihood of material extrusion.

3devo's Solution: Guarantee project success with our Validation Step, leveraging in-depth material insights and a suite of services to enhance your filament extrusion outcomes.

Speed of Development

Pain Point: Need for faster testing in development cycles.

3devo's Solution:

Extrude - Purge - Repeat

Our machines promote rapid prototyping by enabling the quick processing of multiple materials in a single day and providing thorough onboarding for immediate, informed operation.

Process Efficiency

Pain Point: Maximizing machine efficiency for optimal value and results.

3devo's Solution: Our Success Subscription gives you access to our team of Materials Specialists. They will assist as an occasional guide, collaborative partner, or lead navigator, adapting to whatever role best supports your process and goals.

Machine Investment

Pain Point: Difficulty in finding versatile equipment for diverse material experiments.

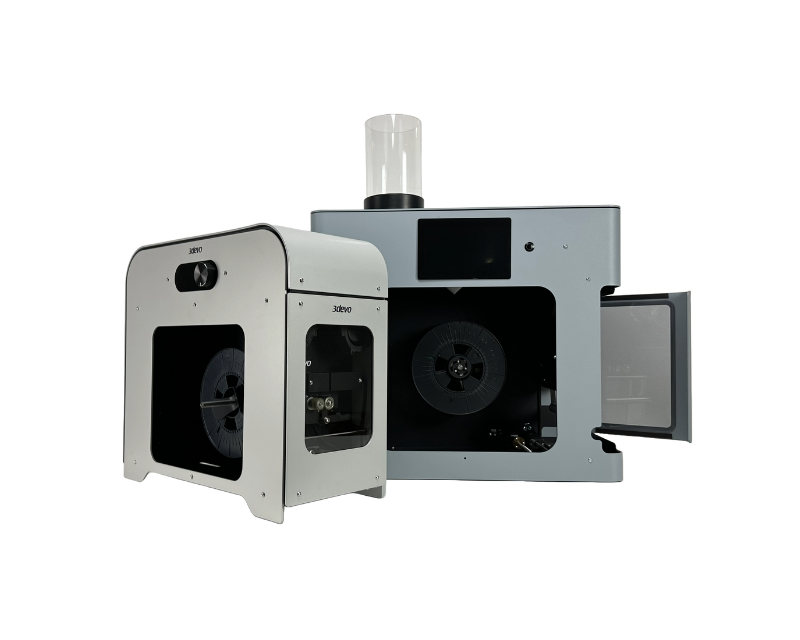

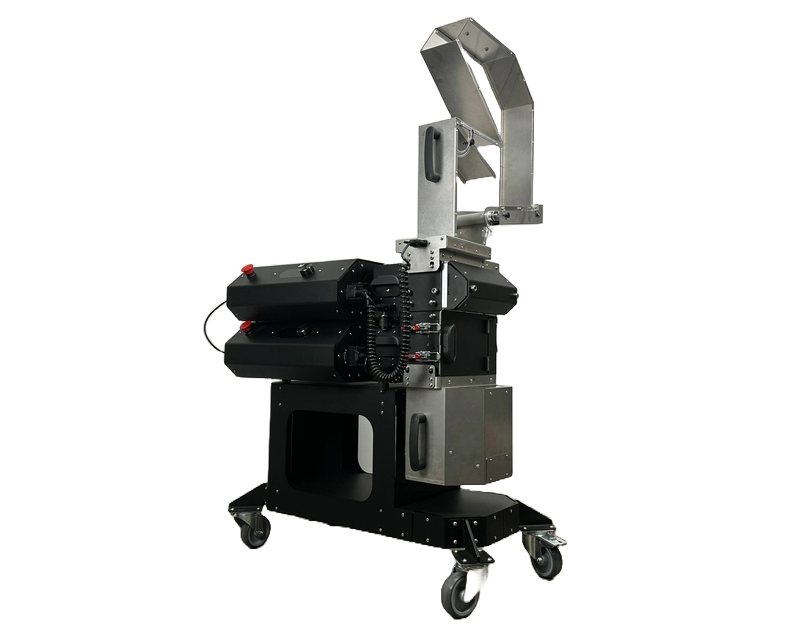

3devo's Solution: Our machines combine intuitive design with an extensive range of material extrusion capabilities. Engineered for versatility, our Filament Makers handle everything from standard to advanced composite materials, ensuring researchers can explore a broad spectrum of filament properties.

How We Do It

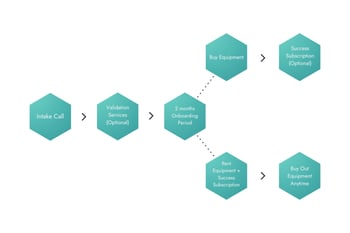

Recommended Journey

Talk to Us

Schedule a consultation with one of our customer success agents to discuss your project and receive a complimentary evaluation on the materials and ROI.

Eliminate Risks

Get a validation service and get insights about your materials extrudability and printing quality.

Buy the Equipment

Purchase the equipment you need and gain full autonomy over the machine(s).

Start your Onboarding

Our team will assist you in getting started quickly and efficiently with our expert onboarding process.

Optional Support

Choose to opt in or out of our Project Consultancy.

Materials

Common waste to recycle

| PET | PLA | PP | HDPE |

| PETG | ABS | PS | LDPE |

| PC | PHB |

Engineering polymers

| TPU | POM | PA6 | PVA |

| TPE | PCL | PA66 | PA |

| ASA | PA12 |

High performance polymers

| PEEK | PEI | PSU |

| PEKK | PPSU |

Additives and composites

Stories like Yours

European Space Agency

How do researchers at ESA have the freedom to innovate – without wasting resources in the process.

Fontys University

How Fontys gained the ability to expand their polymer development studies – at a fraction of the cost.

Sika Automotive

How Sika Automotive managed to reduce their production time for their cavity sealers from weeks to days.

Need a starting point?

We provide material analysis, tailored workshops and dedicated support to guide you to success.

Hear From Our Clients

Frequently Asked Questions

Our Filament Makers and Shredders are designed to handle a wide range of thermoplastics, including common recyclables like PET, PLA, and ABS, as well as engineering polymers such as PEEK and PEI. For a complete list of processable materials and their properties, please visit our Materials section or contact our support team.

We provide a comprehensive validation service that evaluates the extrudability and print quality of your materials. This crucial first step ensures that your project starts on a solid foundation, significantly reducing risks and aligning expectations.

Absolutely! Our machines are specifically designed for rapid prototyping, allowing you to extrude, purge, and repeat the process several times in a single day. This capability accelerates development cycles and enhances your project's agility.

Our solutions are tailored to foster innovation in the 3D printing field, offering versatility in handling various materials, ease of maintenance, and no setup requirements. This allows researchers to focus on innovation without the operational overhead.

You can buy our machines anytime! Just request a quote, and we’ll guide you through the process and provide all the details you need.

Yes, our equipment is capable of extruding blends of polymers along with additives like carbon fiber, ceramic powders, and nanoparticles, enabling you to experiment with custom formulations for specialized applications.

/3devo%20Logo%20Borderless%20-%20Dark%20Mode.png?width=200&height=64&name=3devo%20Logo%20Borderless%20-%20Dark%20Mode.png)