Educators and Lab Managers Fast solutions for reliable filament extrusion results

Accelerate research and sustainability solutions with 3devo

Challenges & Solutions

At a Glance

Industrial Quality

After Sales Support

Easy Maintenance

No Set Up Needed

Onboarding

Two Month Trial

Machine Downtime

Pain Point: Downtime delays research progress and wastes valuable resources.

3devo's Solution: Our industrial-quality machines such as the Filament Makers and GP20 Plastic Shredder are supported by robust after-sales support for spare parts and consumables, minimizing costly downtime.

Material Compatibility & Validation

Pain Point: Wasting time and resources on non-compatible materials.

3devo's Solution: With our validation services, extensive materials database, and expert support, finding the right fit for your projects is streamlined, eliminating the risk of failure.

Our Success Subscription also provides ongoing support at every stage of your project.

Autonomy and Project Ownership

Pain Point: The complexity of introducing new machines to students or technicians

3devo's Solution: Our comprehensive onboarding, support platforms, and safety certifications ensure autonomy from the start. We encourage you and your students/technicians to use the machine as a research tool.

Institutional Bureaucracy

Pain Point: Grant-funded projects can be complicated to navigate.

3devo's Solution: Drawing from our experience with universities and research labs, we offer a flexible business model with adaptable payment and purchasing methods to navigate institutional bureaucracy.

How We Do It

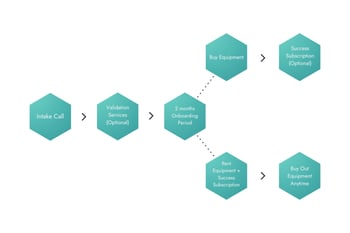

Recommended Journey

Talk to Us

Schedule a consultation with one of our customer success agents to discuss your project and receive a complimentary evaluation on the materials and ROI.

Eliminate Risks

Get a validation service and get insights about your materials extrudability and printing quality.

Start your Onboarding

Our team will assist you in getting started quickly and efficiently with our expert onboarding process.

Buy the Equipment

Purchase the equipment you need and gain full autonomy over the machine(s).

Optional Support

Choose to opt in or out of our Success Subscription.

Materials

Common waste to recycle

| PET | PLA | PP | HDPE |

| PETG | ABS | PS | LDPE |

| PC | PHB |

Engineering polymers

| TPU | POM | PA6 | PVA |

| TPE | PCL | PA66 | PA |

| ASA | PA12 |

High performance polymers

| PEEK | PEI | PSU |

| PEKK | PPSU |

Additives and composites

Stories like Yours

European Space Agency

How do researchers at ESA have the freedom to innovate – without wasting resources in the process.

Fontys University

How Fontys gained the ability to expand their polymer development studies – at a fraction of the cost.

Sika Automotive

How Sika Automotive managed to reduce their production time – for their cavity sealers -from weeks to days.

Need a starting point?

We provide material analysis, tailored workshops and dedicated support to guide you to success.

Hear From Our Clients

Frequently Asked Questions

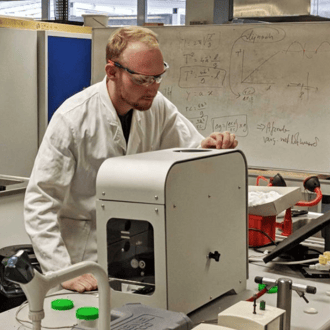

3devo's filament makers and plastic shredder are excellent educational tools that enable students to engage directly with the technologies shaping the future of manufacturing and recycling.

By integrating these tools into curriculum, students can witness the transformation of raw and recycled materials into usable 3D printing filament, which can be applied in various design and engineering projects. This hands-on experience supports active learning and helps students understand complex scientific concepts and sustainability practices in a practical setting.

Our machines are ideally suited for educational programs focused on STEM fields such as mechanical engineering, environmental science, industrial design, and applied chemistry. They allow students to experiment with different materials and understand the properties and behaviors of polymers in a real-world setting. Programs that emphasize sustainable technology, recycling, and innovative manufacturing processes will find these tools particularly valuable.

Absolutely. 3devo offers tailored training sessions that range from basic operations and safety procedures to advanced material science applications. These training sessions can be conducted online or onsite and are designed to empower educators and technicians with the skills needed to utilize our equipment effectively in their teaching and research.

Continuous support and updated training materials are also provided to ensure that users can keep pace with advancements in technology and teaching methodologies.

Yes, our machines are designed with multiple safety features to ensure they are classroom-friendly. Features include protective casings to prevent accidental contact with hot surfaces, automatic shutoff mechanisms in case of malfunctions, and detailed safety instructions. Each unit is rigorously tested to meet high safety standards before it is deployed in an educational setting, ensuring a safe learning environment for all users.

3devo actively promotes project-based learning by enabling students to take ownership of their creative and technical projects from conception to realization. Our machines serve as a bridge between theoretical learning and practical application, allowing students to explore innovative solutions to real-world problems, such as creating sustainable materials or custom-engineered parts. This approach not only enhances technical skills but also encourages critical thinking and problem-solving abilities.

Investing in 3devo equipment is justifiable on multiple fronts: educational enrichment, cost reduction, and environmental impact. These machines provide students with unique learning opportunities that can significantly enhance their employability and technical skills. Additionally, by recycling waste materials into valuable 3D printing filament, institutions can significantly reduce their materials costs. Moreover, promoting sustainability aligns with global educational goals and can enhance the institution's reputation as a leader in innovative and eco-friendly education.