Plastic Extrusion Machine

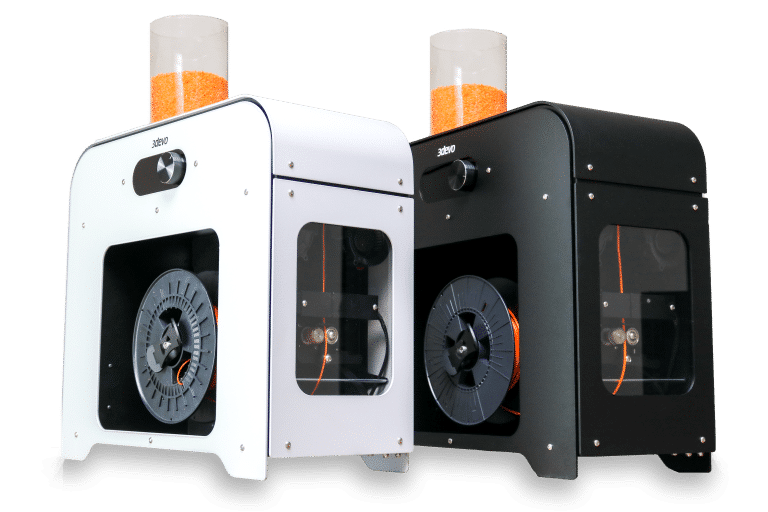

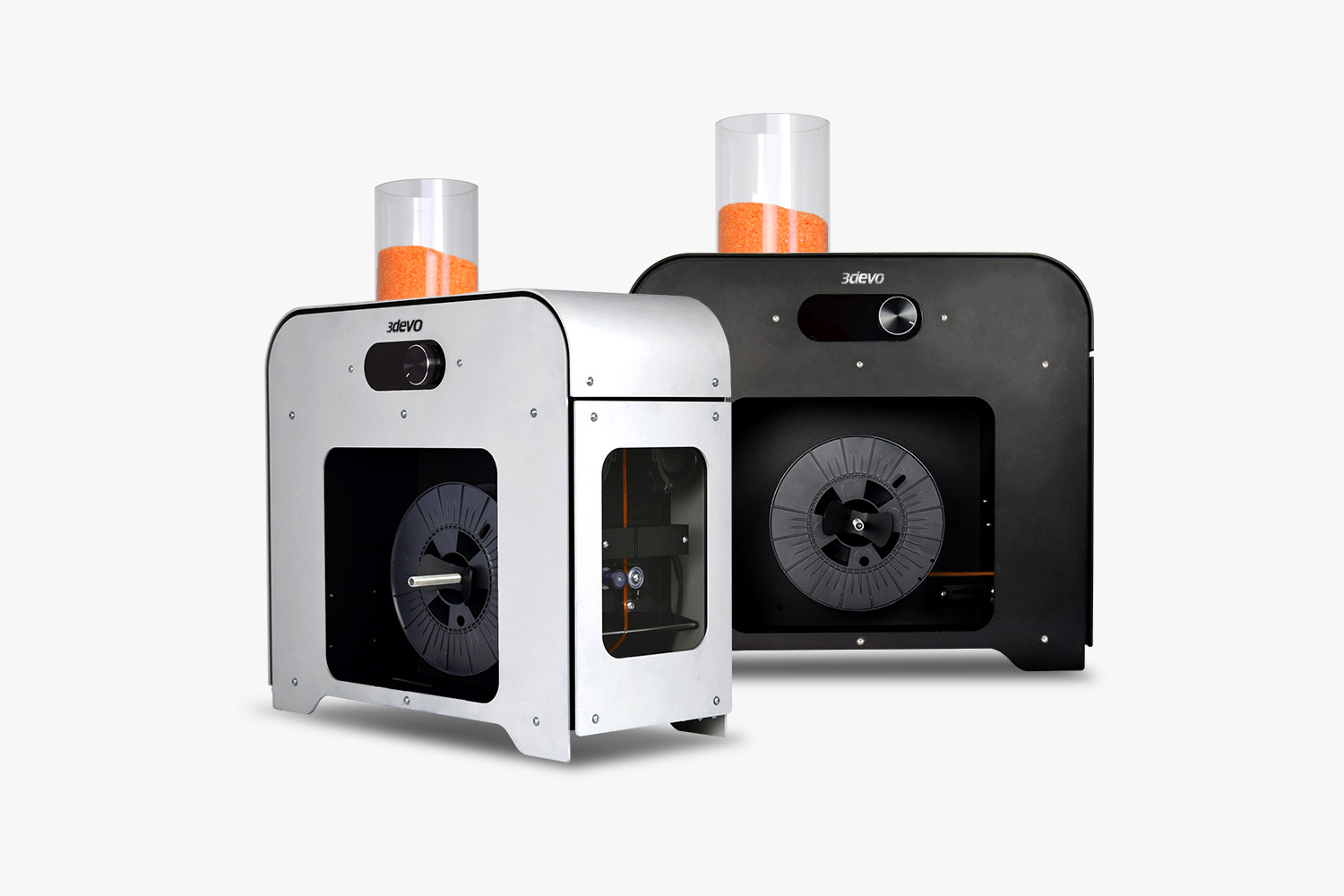

Looking for a plastic extrusion machine to enhance your 3d printing process? 3devo both designs and builds products that fully cover the whole filament extrusion circle in house, making sure we make filament extrusion simple for everyone. We try to provide you with the best user friendly desktop solutions. From a filament extruder, to a filament recycler, to a polymer dryer, you get powerful, reliable solutions that meet your unique needs. This creates a highly customizable approach to 3d printing for our customers: one that increases productivity, output and creativity, while reducing costs.

What is extrusion?

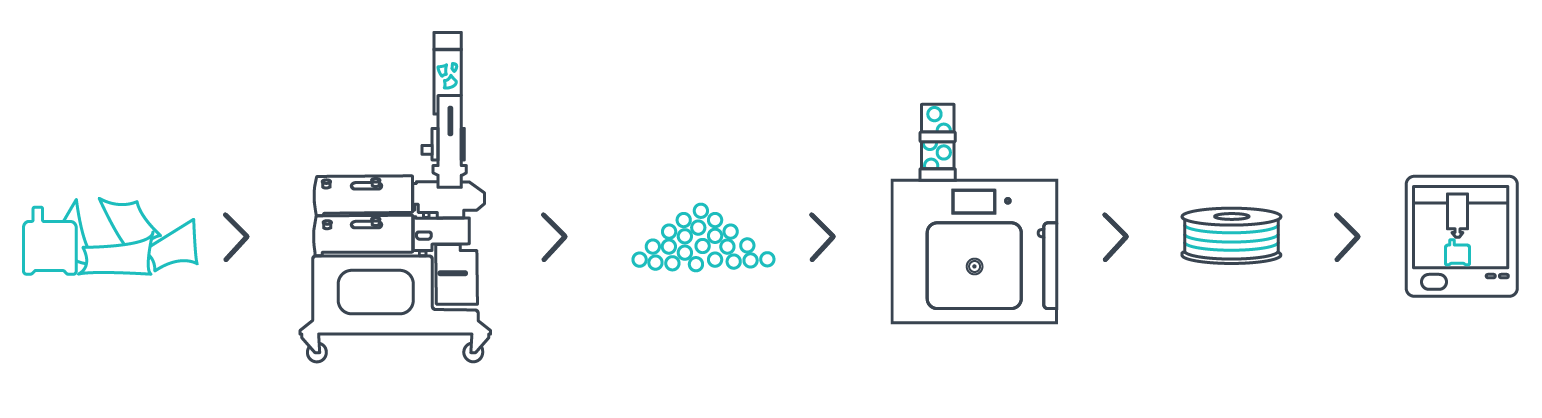

Plastic extrusion is a high-volume manufacturing process in which raw plastic is melted and formed into a continuous profile. At 3devo we make sure small-batch extrusion is accessible to everyone. You can now convert raw plastic pellets into filament wires with our desktop extrusion machine. This filament is the input material for 3D printers. It’s a whole new way to take 3D Printing to a new level.

Our Filament Makers are trusted by businesses around the globe

Extrusion process made simple

Prior to beginning the plastic extrusion process, the proper machinery and supplies must be obtained, specifically a plastic extrusion machine. Our desktop extrusion machine helps you break new ground in the development, production, and recycling of 3D printing materials. Redefining extrusion. It has everything you need to facilitate the extrusion process from start to finish – right at your desk. Making materials simpler than ever to work with, while offering even more possibilities in manufacturing and innovation.

The main components of our desktop extruder machine include a control panel, hopper, extruder, cooling system, diameter sensor, puller system, filament positioner, and spool winder. Use only the most durable and versatile components to make sure that you will be able to recycle your plastics for a long time.

At 3devo we get the importance of screw design. Since the heating rate, feed rate, and other integral extrusion factors are directly dependent on the only moving part in the plastic extruder—the screw—careful consideration of the size and design of this component is necessary. The extruder screw in our filament makers is machined for mixing. Its nitride-hardened interior ensures industrial-grade filament extrusion.

Ready to start efficient and affordable experimentation, to produce custom filament and give old plastics a fresh lease of life? Our all-in-one professional desktop extruder enables it all. The machine is perfectly suitable for small batch extrusion in short time frames and allows you to immediately proceed with material testing and analysis. Check out our products and start reinventing your own 3D printing process.

Need any help? We are here to answer all your questions. Don’t hesitate to contact us.

Reduce filament costs up to 10 fold

Produce filament at rapid speeds

Let’s Talk Extrusion & Materials

Do you want to discuss your unique application? Ask one of our extrusion experts today.