Reusing and repurposing plastic waste is an ideal way to cut down on the amount of garbage you put in your landfill, while you are saving on materials.

Extrusion in Automotive

Let Innovation Hit Top Gear

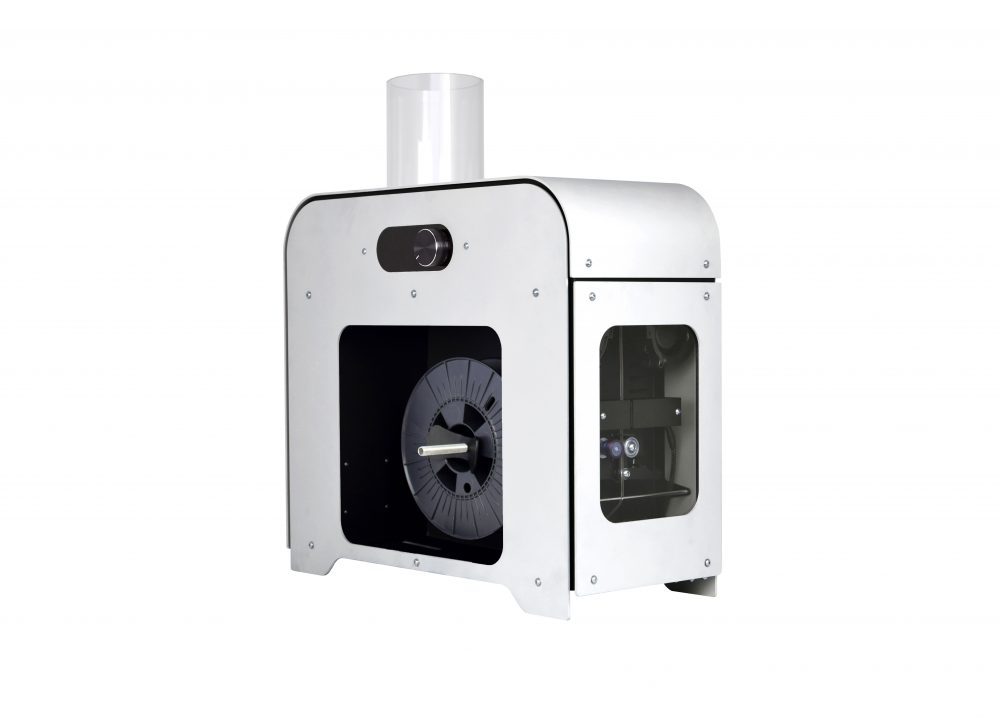

With professional desktop extrusion supporting your in-house 3D printing setup, creating durable custom filament has never easier – or faster. Develop, test and tweak custom automotive parts and components in the ideation phase itself. Reduce development lead times, save R&D costs, and enjoy cruise control over your long-term development goals.

Benefits of Extrusion

Reduce Costs & Save Time

Compact desktop filament extruders deliver flexibility and convenience in extrusion—reducing lead times while cutting costs.

Convert Waste into Resources

Infinite Testing & Prototyping

Infinite testing and prototyping allows you to collect maximum insights from minimum resources.

Why Choose 3devo in Polymers?

Speed Up Development

Rapid prototyping

Experimentation

Customization

Enhancement

Recycle

Get Inspired

Make stronger, more flexible, less expensive materials for use in a multitude of applications. Learn how some of the biggest manufacturing companies are now incorporating filament extrusion into their production processes.

Fast-track Material Prototyping

Our filament makers get your automotive design facility on the express lane to efficient innovation. By enabling you to experiment with a broad range of custom materials, it expedites personalized prototyping, and saves valuable time and development costs.