Turn Your Plastic Waste into High Performance Filament

- Test new materials on a small scale, without large production costs.

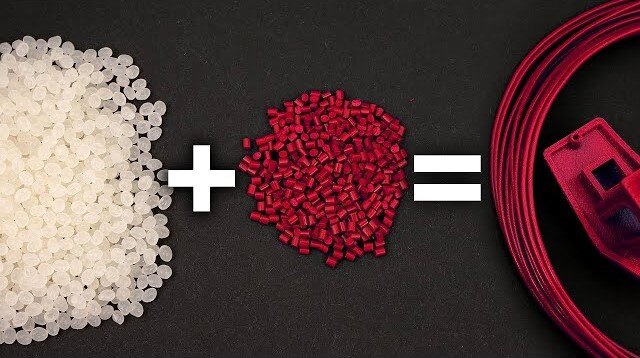

- Recycle plastic waste into usable filament, supporting your sustainability goals.

- Tailor filament properties to meet the specific needs of your project.

- Intuitive controls and minimal setup allow anyone to start extruding in no time.

Schedule Your Free 15-minute Consultation With Our Experts

Trusted By:

Trusted By the Best Researchers and Engineers:

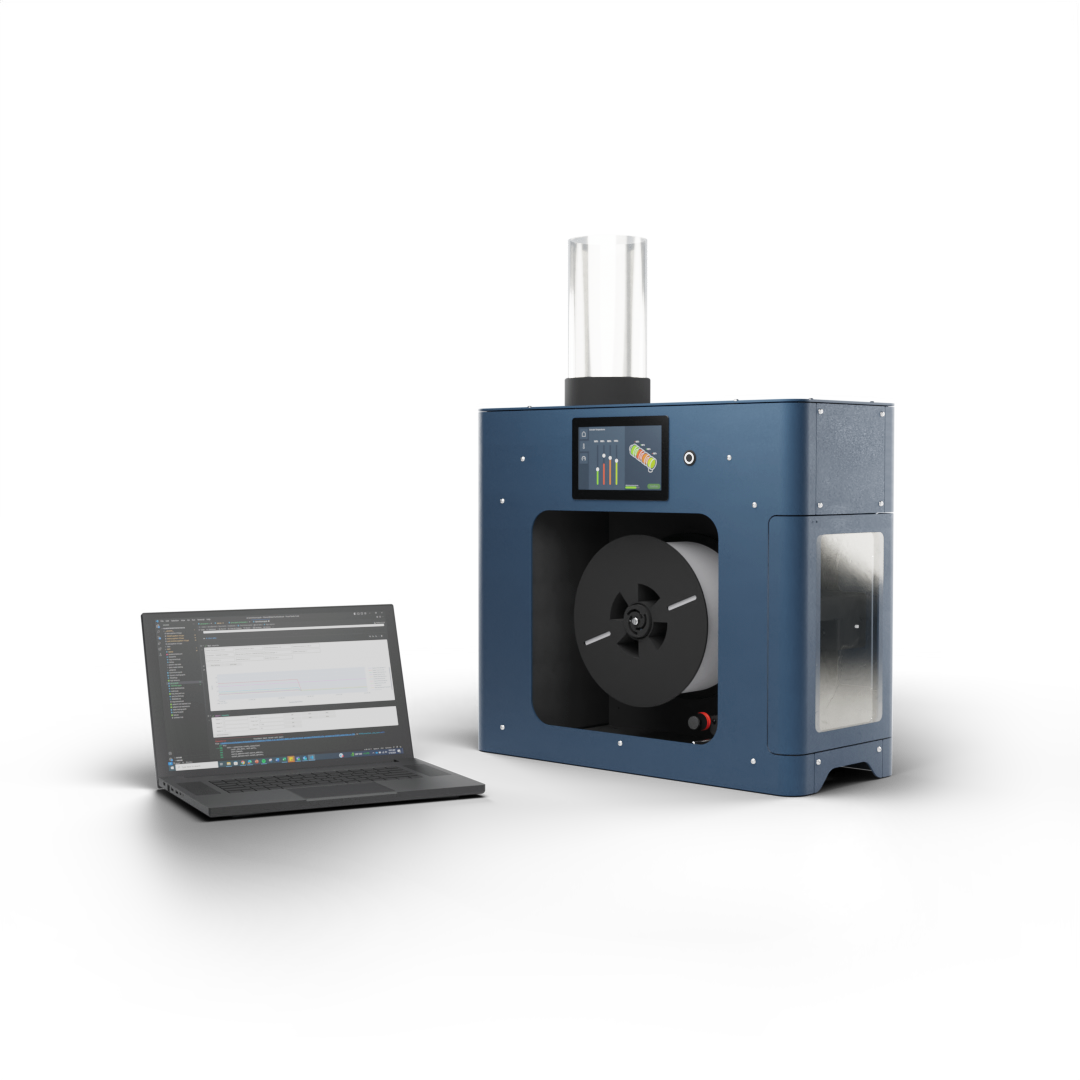

Our Filament Production Machines

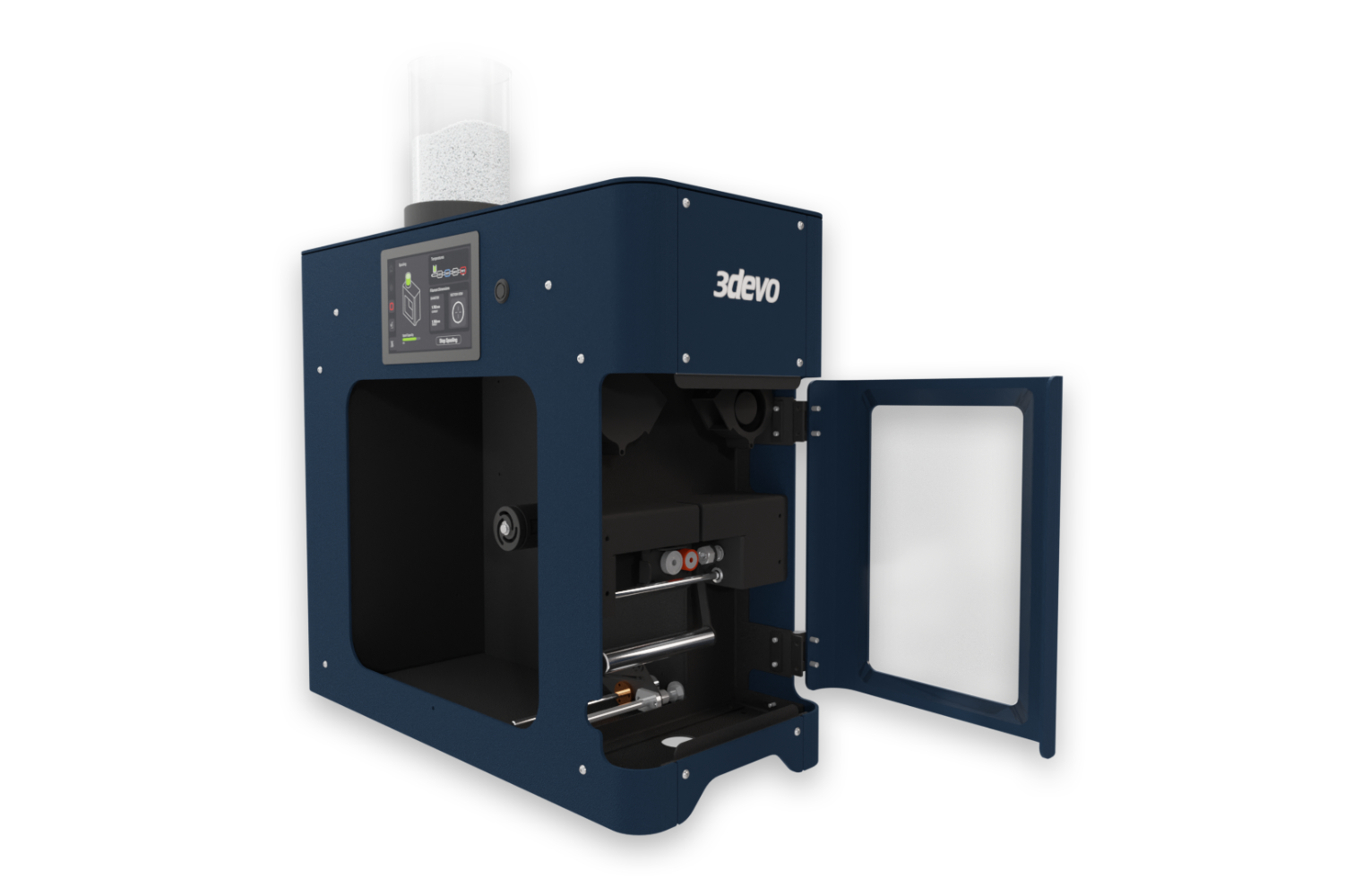

Filament Maker TWO

The ultimate tool for your 3D printing projects. Packed with the latest tech, it's ready to create high-quality filament for your work.

Filament Maker Composer

The Composer offers an easy-to-use and durable solution for creating custom 3D printing filament in a sleek, compact design.

Filament Maker Precision

The Precision model delivers top-notch, high-temp filament extrusion with speed, consistency, and user-friendly operation.

GP20 Plastic Shredder

The GP20 Plastic Shredder breaks down plastic waste, simplifying the recycling process for creating new 3D printing filament and supporting sustainable production.

Highlighted Features of

Filament Maker TWO

The Filament Maker TWO is designed for efficiency and ease of use, featuring smart controls and adaptable components. It brings precision and flexibility to your filament-making process, making it simple to create high-quality results.

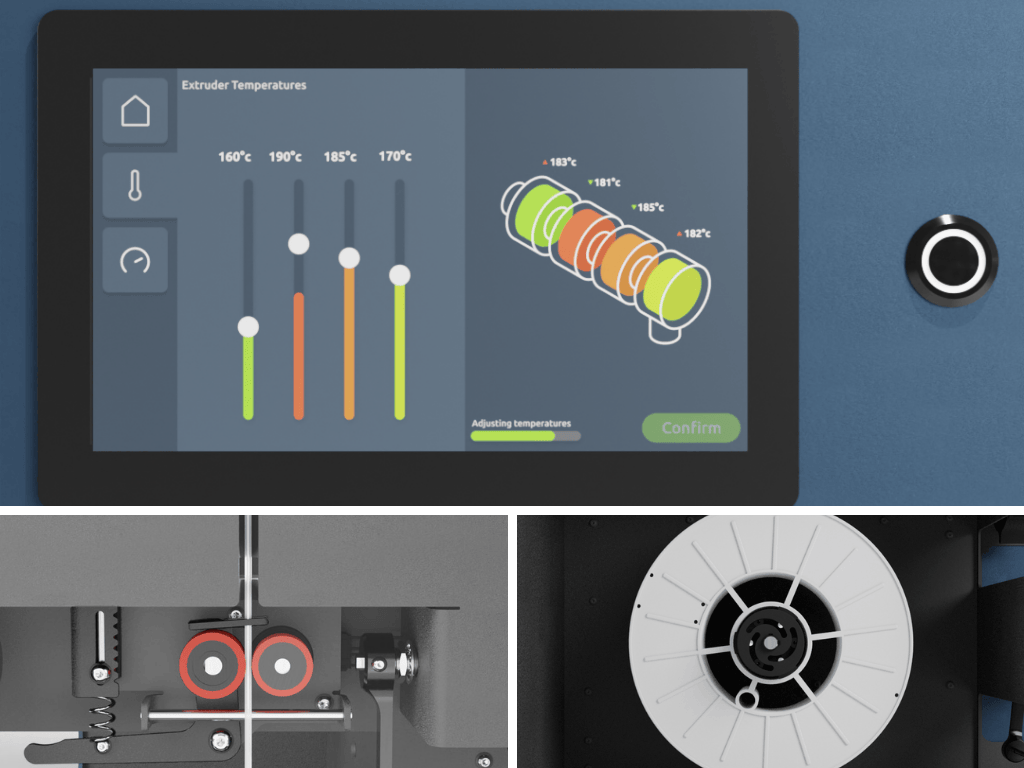

Touchscreen Interface

Easily access settings, monitor progress, andmake adjustments for a seamless experience.

Variable Puller

Adjust the puller force to accommodate different materials, ensuringoptimal tension and consistent filament quality. Switch between

flexible and rigid materials with ease.

Spool Chuck

Secure spools quickly and easily, reducing setup time andenhancing convenience.

3 Axis Measurements

By measuring the filament from three sides, the sensor can detect anyovality, ensuring the filament maintains a uniform round shape.

Thermal Sensor

The thermal sensor accurately measures the filament temperaturejust before it reaches the puller wheels. This allows for precise

adjustments to prevent filament squishing and ensures

consistent filament quality.

Coming 2025: Image Processing

The image processing capability allows for real-time monitoring ofthe filament's integrity. It helps identify and correct any imperfections,

leading to a more consistent and reliable filament output.

.png?width=1080&height=810&name=Webpage%20-%201024x768%20(6).png)

Easy Disassembly

Quick access to components allows for fast and straightforwardmaintenance. Parts can be easily removed and reassembled without

the need for specialized tools or extensive knowledge.

Screw Removal

Simplified cleaning with our enhanced compression screw removalprocess. Effortlessly remove the screw for thorough cleaning,

reducing downtime and ensuring your filament maker operates

at peak performance.

Data logging

Enables continuous data collection for real-time analytics,as well as retrieval and one-time plotting of older data.

This creates a customizable environment for tracking

and analyzing your filament-making process

on the Filament Maker TWO.

API Access

Our API allows real-time data retrieval and machine control.Customize operations to fit your specific needs.

Coming 2025

CAN-bus - Easily add and integrate new modules with our CAN-bus protocol.This open system provides power and communication

for custom add-ons.

Materials

Common waste and commodity polymers

| PP | PET | PLA |

| HDPE | PETG | ABS |

| LDPE | PS | PHB |

Engineering polymers

| TPU | PCL | PPS | PA6 |

| TPE | PC | POM | PA66 |

| PVA | ASA | PA | PA12 |

High performance polymers

| PEEK | PEI | PSU |

| PEKK | PPSU |

Ideal Applications for Our Filament Makers

Material Recycling

Turn your plastic waste and failed 3D prints into valuable resources. Save money by converting waste into a valuable asset.

Education

Discover and experiment with innovative polymers, analyze their properties, and create a platform to educate on their use.

Research and Development

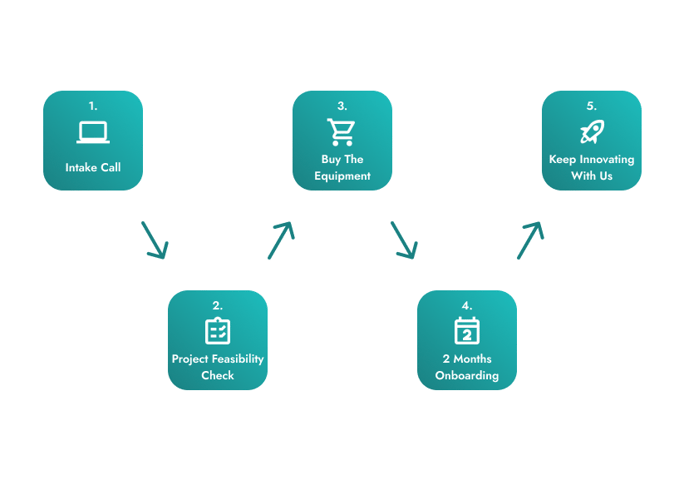

Our Approach

Purchase or rent the equipment or transition between options without any restrictions

Explore Our Machines in Action with CNC Kitchen

Explore 3D printing innovation with Stefan from CNC Kitchen. See our Filament Makers in action.

Extruding PLA Filament

- The video shows how to make custom 3D printing filament using the 3devo filament extruder.

- It covers the extrusion process and briefly mentions recycling failed prints.

- The 3devo machine is aimed at labs, not home users.

I made Coffee 3D Printing Filament

- The video shows how to make 3D printing filament by mixing spent coffee grounds with PLA.

- It covers the process, challenges in printing, and the material's mechanical properties.

- It highlights the ecological benefits and unique features like texture, color, and smell.

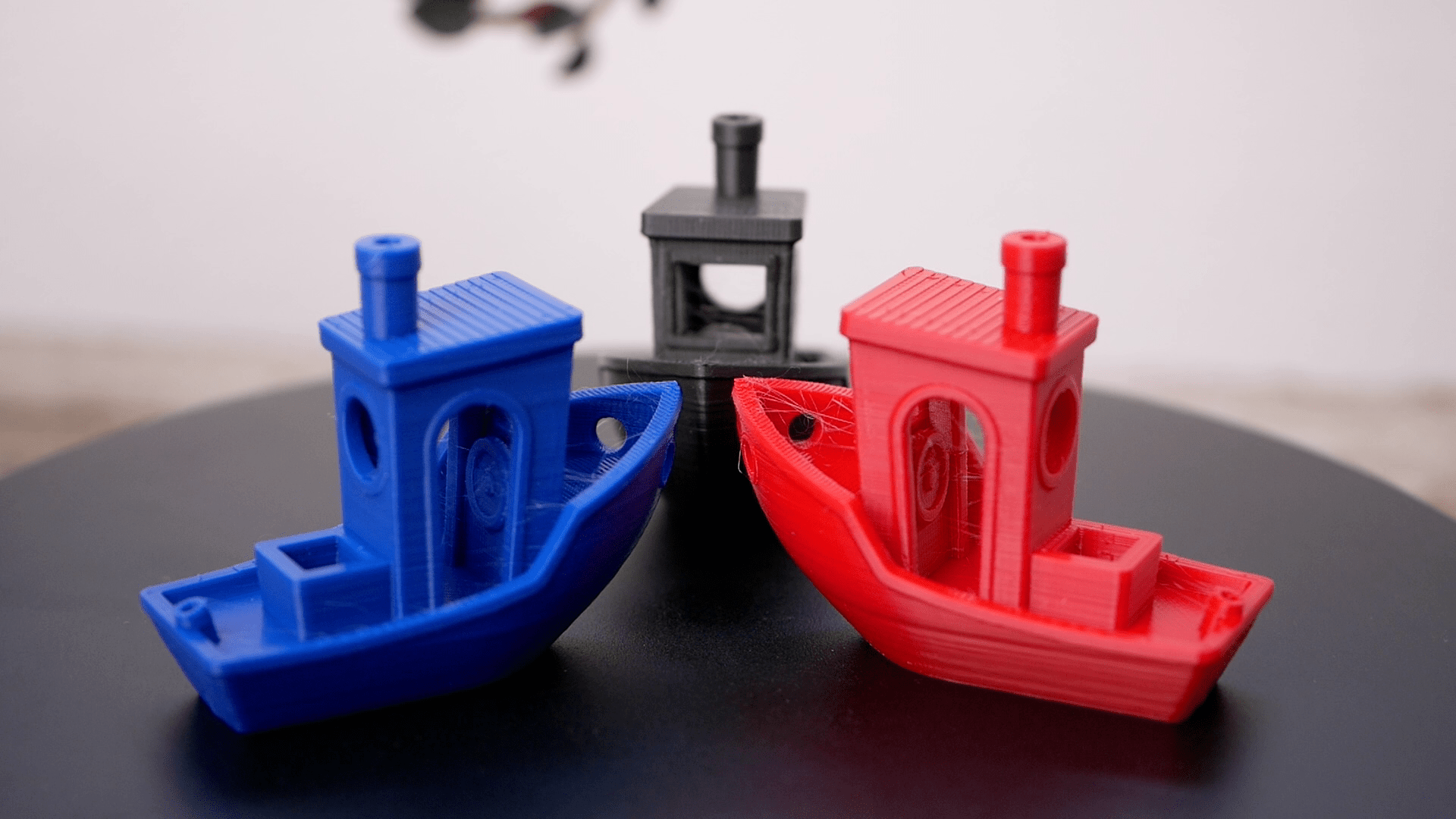

Recycling all my 3DBenchys into new Filament

- The video shows recycling over 100 failed 3D prints into new filament and tests its quality and strength.

- It covers challenges like contamination and extrusion inconsistencies.

- The recycled filament was only slightly weaker than new PLA, proving recycling is possible.

Validate Your Materials with Our Experts

Not sure if your material can be extruded? Our team of material experts can help you figure it out before you commit to a machine. We’ll guide you through testing and validation to see if your project is possible. Book a free consultation, and let’s explore if your material is ready for 3D printing success.

Why choose 3devo?

See Results or Get a Refund

We offer a 2-month trial phase to give you the opportunity to test our solutions with no long-term commitment. During this period, you can explore the features, experiment with your materials, and see how the equipment fits into your workflow.

Our goal is to make sure you're confident in your decision before fully committing. It’s a risk-free way to experience the benefits without any pressure.

Professional Onboarding

Our expert Customer Success Managers will be there every step of the way. They’ll provide personalized guidance, help you navigate the equipment, and offer support to make sure you’re getting the most out of your trial experience.

Whether it’s optimizing settings or answering any questions, our team is dedicated to helping you succeed and ensuring the equipment integrates smoothly into your workflow.

Buying or Renting Plans

Flexible pricing options let you choose what fits your needs best. Renting gives you the freedom to test the equipment without the full upfront commitment, while buying offers a long-term investment in your operations.

Whether you need a short-term solution or are ready for full ownership, you have the flexibility to adapt to your project’s demands. This customized approach ensures you get the right setup, when and how you need it.

Our Success Stories