Share this

Zortrax Filament - Extruding the Filament

by 3devo on Sep 6, 2017 4:38:00 PM

Zortrax is a name renowned for precision engineering. Most famous for their exclusive line of 3D printers, namely the M300 and M200, creating high quality prints with ease. However, Zortrax also shine in their range of filaments. These all boast great qualities and are ideal for a range of uses from prototypes to decorative elements.

Zortax range of 3D Printers (photo via Zortax)

We soon decided to focus on one of their more popular filaments: Z-ULTRAT. Therefore, we wanted to see how well it would extrude, and what use it could be for you or your business.

Filament Summary

Z-ULTRAT filament (photo via Zortax)

The Z-ULTRAT is no ordinary filament, designed purely for its own Zortrax M200 3D Printer. Its main features (high hardness and durability) make it great for prototyping mechanical parts, architectural models and design prototypes. Below are its key features:

| Name | Z-ULTRAT 3D Printing Filament Cool Grey 1.75mm 800g |

| Filament Material | ABS |

| Printing Technology | LPD (Layer Plastic Deposition) |

| Dedicated Device | Zortax M200 3D Printer |

| Features | – Durable and Strong – High Hardness Level – Low Elasticity – Low Level of Deformation |

| Weight | 1kg (2.2lb) gross wt./ 800g (1.76lb) net. wt. |

| Efficient Melting Point for 3D Printing | 269 – 279°C [516 – 534°F] |

| Glass Transition Temperature | 144°C [291°F] |

| Vicat Softening Temperature | 130°C [266°F] |

| Thermal Expansion | Minimal |

| Odor | Nearly Odorless |

| Hazards | Product does not present any hazard while operating |

For more information visit the official Zortrax Z-ULTRAT page.

While these are all good features, it is not so easy for extrusion. Especially when comparing it to PLA. The next step will look at testing how well the filament extrudes using our filament extruder.

Extruding Z-ULTRAT 3D Printing Filament

Failed prints used for testing

Pre-Conditions

The Precision 350 was used for the tests, and was set to 220 °C across all three sections. The purpose for using the regular extruder as opposed to the Advanced version, is due to the extrusion screw of the model. It has been previously observed that the Regular screw, lacking the pineapple mixing station, is generating more pressure. Better nozzle flow is a result of this.

The machine is pre-loaded with HDPE. This is to ensure the extrusion barrel and screw are clean and performing at an optimum level upon receiving the Zortrax ABS. In order to remove all contaminants, the machine was left to run HDPE for an hour. The filament was added after this step.

Results

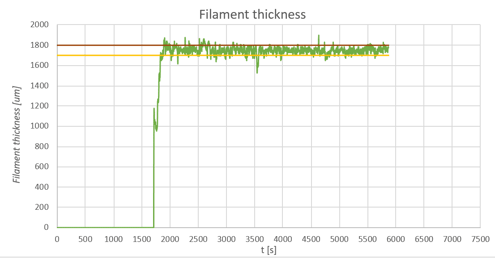

Numerous tests were completed using different settings in order to achieve industry-standard results. Below is a graph showing off the stability over time:

Filament thickness results over time after extrusion

In the end, the filament became stable at: 1 – 275 / 2 – 280 / 3 – 270 at speeds of 5rpm.

Left to Right: Shredded Filament into the extruder, final result of the Z-ULTRAT

The filament produced better results after changing the speed to 5rpm, with only slight deviations (still within 100 microns) over 35-40 minutes. As a result, the test was a success. This was because a thickness of 1.75mm is not easy to extrude, as more control is needed. Also noted that ABS is harder to extrude when compared to other filaments such as PLA.

Conclusion

Zortrax robotic arm printed using the M200.

The Zortrax range of 3D printers and filaments offer fantastic end results. Mechanical parts, casing elements for testing and even consumer and educational product prototypes – all are possible, with complimentary colours to go with. Furthermore, you have the option of recycling your prints after you are done. This means both businesses and printing enthusiasts alike will be able to take full advantage of these great products.

Share this

- November 2025 (1)

- October 2025 (1)

- March 2025 (1)

- January 2025 (1)

- December 2024 (2)

- November 2024 (2)

- October 2024 (4)

- September 2024 (2)

- August 2024 (3)

- July 2024 (6)

- June 2024 (3)

- May 2024 (2)

- April 2024 (1)

- March 2024 (1)

- January 2024 (1)

- November 2023 (2)

- October 2023 (5)

- September 2023 (2)

- August 2023 (1)

- July 2023 (1)

- May 2023 (1)

- December 2022 (2)

- June 2022 (1)

- May 2022 (2)

- April 2022 (2)

- March 2022 (6)

- February 2022 (2)

- January 2022 (3)

- December 2021 (3)

- November 2021 (3)

- October 2021 (2)

- September 2021 (3)

- August 2021 (3)

- July 2021 (2)

- June 2021 (1)

- March 2021 (1)

- October 2020 (1)

- June 2020 (1)

- May 2020 (1)

- April 2020 (4)

- November 2019 (1)

- July 2019 (2)

- June 2019 (1)

- May 2019 (1)

- March 2019 (1)

- November 2018 (1)

- September 2018 (1)

- January 2018 (1)

- October 2017 (1)

- September 2017 (1)

- July 2017 (1)

- June 2017 (1)

- May 2017 (1)

- January 2017 (1)

- December 2016 (3)

- November 2016 (2)

- October 2016 (1)

- May 2016 (2)

- August 2015 (2)

- July 2015 (1)