Share this

PET Recycling - From Bottle to Filament

by 3devo on Sep 25, 2018 11:35:00 AM

.png?width=1500&height=630&name=new2-1500x630%20(1).png)

Recycling. A word often related to large companies receiving tons and tons of paper or plastic in an effort to reduce our carbon footprint. However if we look at plastic bottles for instance, humans buy a million plastic bottles per minute, and 91% of all plastic is not recycled. This article is going to cover what makes plastic recycling so important, how to recycle PET and the future of recycling in 3D printing.

What is PET Recycling?

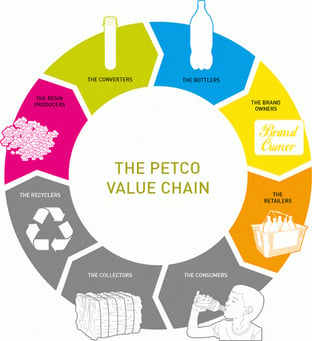

Focusing on plastic bottles here, they have one huge advantage - unlimited recycling potential. PET is one of the few polymers that can be recycled into the same form over and over again. Think of it as a closed-loop recycling solution.

Recycled PET, or rPET, can be used to make many new products. This can range from clothing, automotive parts, packaging as well as bottles for food/non-food products. Depending on the application required, rPET will be blended with the original PET.

What Are The Uses of Recycled PET (rPET)?

As mentioned above, rPET has many great uses, which includes:

- Food containers

- Polyester carpet fiber

- Fabric for T-shirts

- Athletic shoes

- Luggage and upholstery

- Sweaters and fiberfill for sleeping bags and winter coats

- Industrial strapping

- Sheet and film

- Automotive parts

- New PET containers

Using rPET in place of virgin PET has substantial environmental impacts as well as reducing overall energy consumption.

Creating Our Own Filament from Plastic Bottles

Now that we’ve covered the background of recycling PET, how exactly does one go about doing the actual recycling? The one method is simply going to your local recycling company and dumping your plastic waste there, or having it picked up at home if that company provides a pick-up functionality. The other method though is a bit more rewarding – doing it yourself.

We wanted to test of normal plastic bottles can be turned into 3D printing filament. Here is a summary of the steps we took to test turning 30 PET bottles into filament:

- Water bottles were collected, cleaned (properly) and any external caps or seals were also removed,

- The bottles were then vacuum sealed and heated to reduce their size,

- Once cooled the bottles were cut into smaller chunks with a saw and a pair of scissors,

- After that, the pieces were shredded into tiny pieces using our SHR3D IT,

- The pieces were then dried at a temperature of 160°C for 4 hours,

- The PET was then fed into our Precision 350 filament extruder,

- After multiple tests at different nozzle diameters and temperatures, our team ended up with a great result of PET filament.

The Future of Plastic Recycling in 3D Printing

The biggest issue that faces 3D printing recycled filament – dirt. With the above experiment, just cleaning those bottles took a great deal of effort. Now imagine doing it with tons of plastic, often coming from dumps that have been contaminated all forms of impurities.

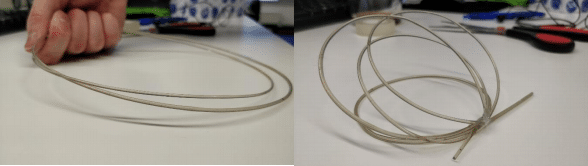

Also, one has to take note that different types of plastic produce different types of filament. High-density polyethylene — shampoo bottles, for example — are relatively easy to convert into filament, but it’s difficult to print with because it shrinks more than other plastics as it cools. On the other hand, PET, prints well but is brittle, making it difficult to spool as filament.

Recently, we saw the US Department of Defense (DoD) is exploring 3D printing feedstock made from plastic containers that have been left on the battlefield, which can hopefully be reproduced in other government sectors. There’s also Ethical Filament, a company focused on promoting the concept of recycling to produce ethical 3D printing filament that is sold to improve the livelihoods of waste pickers and their communities worldwide. Then there’s the Perpetual Plastic Project (PPP), which is an installation which can directly recycle old plastic drinking cups into 3D printing gadgets as well as other plastic products if needed.

While there is more and more aware of using recycled filament for 3D printing, we still have a long way to go. Hopefully, with the rise in 3D printing over the last few years, more emphasis is being placed on plastic recycling.

Share this

- November 2025 (1)

- October 2025 (1)

- March 2025 (1)

- January 2025 (1)

- December 2024 (2)

- November 2024 (2)

- October 2024 (4)

- September 2024 (2)

- August 2024 (3)

- July 2024 (6)

- June 2024 (3)

- May 2024 (2)

- April 2024 (1)

- March 2024 (1)

- January 2024 (1)

- November 2023 (2)

- October 2023 (5)

- September 2023 (2)

- August 2023 (1)

- July 2023 (1)

- May 2023 (1)

- December 2022 (2)

- June 2022 (1)

- May 2022 (2)

- April 2022 (2)

- March 2022 (6)

- February 2022 (2)

- January 2022 (3)

- December 2021 (3)

- November 2021 (3)

- October 2021 (2)

- September 2021 (3)

- August 2021 (3)

- July 2021 (2)

- June 2021 (1)

- March 2021 (1)

- October 2020 (1)

- June 2020 (1)

- May 2020 (1)

- April 2020 (4)

- November 2019 (1)

- July 2019 (2)

- June 2019 (1)

- May 2019 (1)

- March 2019 (1)

- November 2018 (1)

- September 2018 (1)

- January 2018 (1)

- October 2017 (1)

- September 2017 (1)

- July 2017 (1)

- June 2017 (1)

- May 2017 (1)

- January 2017 (1)

- December 2016 (3)

- November 2016 (2)

- October 2016 (1)

- May 2016 (2)

- August 2015 (2)

- July 2015 (1)