Share this

Extruding PVA Filament

by 3devo on Dec 2, 2016 10:23:00 AM

PVA or polyvinyl alcohol is a relatively rare material in industry and is usually very difficult to process. Water acts like a plasticizer for PVA and the material is water soluble. This means that any humidity can adversely affect its performance and even eventually break it down.

VA is used in glues and also in bait bags for fishing carp for example. Bait is inserted in the bag and this is put into the water to attract fish. Once the bait bag dissolves in water, the bait spreads around the hook leading to more fish more likely to bite.

The fact that PVA is water soluble and considered safe means that for a number of years it has been seen as the ideal support material for FDM 3D printing.

Fused Depositioning Modeling (FDM, also called FFF) systems use a nozzle to extrude and lay down plastic filament such as ABS or PLA. A build platform is then lowered and a new layer is applied. Industrial 3D printing systems have long used a second nozzle to extrude a sacrificial support material to support overhangs in the 3D print. This material is later removed.

Sometimes supports can be a breakaway support structure or a material that has a lower head deflection temperature or strength than the build material. Stratasys, the company that invented FDM, has a wax support material for example.

The company also offers:

- PPSF support material (polyethersulfone),

- Polystyrene support material which is meant to be removed manually,

- A water soluble support material called 2-Propenoic acid, 2-methyl-, polymer with methyl 2-methyl-2-propenoate which is an acrylic,

- Terpolymer of Methacrylic Acid, Styrene, and Butylacrylate.

Depending on the 3D printing process, the build material and the requirements of the part, many different supports are available.

Virgin PVA Granules with a much needed desiccant bag.

For the desktop 3D printing community however PVA is the most researched and most coveted. PVA’s environmentally friendly characteristics coupled with the ease of use in removing the supports have lead to many companies looking into it.

However, PVA is notoriously difficult to keep. It must be dried before use. Even then, in a normal room PVA can quickly be adversely affected by moisture in the air. In some cases a mere 12 hours in a room may degrade the material considerably.

During normal 3D printing operations the material can also degrade much faster than other materials. What we discovered in our experiments with the material is that in addition to these issues care must be taken when extruding it. Any PVA remnants inside nozzles for example can wreak havoc on subsequent 3D prints and extrusions.

This is also one of the reasons (along with nozzle lifting and software) while dual extrusion and support material on desktop 3D printers is so difficult to do.

Many companies have researched dual extrusion and are trying to implement it. The difficulty of working with the engineering, software and material however has lead to only precious few 3D printing companies actually being able to make dual extrusion with PVA a reality. Even of those who say they can do several can not reliably do it.

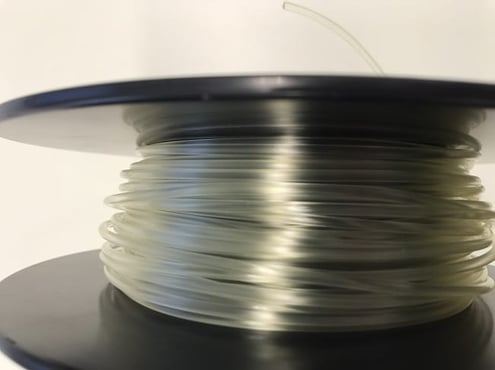

A Spool of PVA filament made with 3devo’s Composer 450 filament maker

After drying out and extruding the material we were able to create good PVA filament with it in less than half a day of testing. The material was tested in prints and as a support and performed well.

We will continue to share our learnings with you, whether it’s about extruding PVA filaments, or PEEK! Stay tuned to our blog to read about our latest experiments!

Share this

- November 2025 (1)

- October 2025 (1)

- March 2025 (1)

- January 2025 (1)

- December 2024 (2)

- November 2024 (2)

- October 2024 (4)

- September 2024 (2)

- August 2024 (3)

- July 2024 (6)

- June 2024 (3)

- May 2024 (2)

- April 2024 (1)

- March 2024 (1)

- January 2024 (1)

- November 2023 (2)

- October 2023 (5)

- September 2023 (2)

- August 2023 (1)

- July 2023 (1)

- May 2023 (1)

- December 2022 (2)

- June 2022 (1)

- May 2022 (2)

- April 2022 (2)

- March 2022 (6)

- February 2022 (2)

- January 2022 (3)

- December 2021 (3)

- November 2021 (3)

- October 2021 (2)

- September 2021 (3)

- August 2021 (3)

- July 2021 (2)

- June 2021 (1)

- March 2021 (1)

- October 2020 (1)

- June 2020 (1)

- May 2020 (1)

- April 2020 (4)

- November 2019 (1)

- July 2019 (2)

- June 2019 (1)

- May 2019 (1)

- March 2019 (1)

- November 2018 (1)

- September 2018 (1)

- January 2018 (1)

- October 2017 (1)

- September 2017 (1)

- July 2017 (1)

- June 2017 (1)

- May 2017 (1)

- January 2017 (1)

- December 2016 (3)

- November 2016 (2)

- October 2016 (1)

- May 2016 (2)

- August 2015 (2)

- July 2015 (1)