Share this

Is PETG The Best Filament in the 3D Printing Industry?

by 3devo on May 17, 2017 11:21:00 AM

When it comes to 3D printing, information about filaments such as PLA and ABS is plentiful. However there is another filament out there – PETG. With its strong, durable, and ease of use characteristics, are making it more and more popular by the day. 3devo delves into what PETG is, how it compares to the aforementioned polymers in terms of printing and extrusion.

What is PETG?

Source: Pixabay

PETG first started as simply PET, or polyethylene terephthalate. PET had and still has many great uses, with its fibers being used everywhere from food packaging to plastic bottles, as well as other common plastic items. There are many variations of PET, such as ETE, PETP, PET-P, etc., however, the G in PETG stands for glycol. Glycol prevents crystallization in the thermoforming process (i.e. preventing it from turning hazy).

Thanks to the glycol, it means the classic PET is modified for extra durability. PETG has recently become very popular as 3D-printing filament due to this durability, so let’s take a closer look at what makes it so great.

Why did we choose to test PETG?

Source: 3devo testing area – PETG (Genius 80M) in its granular form.

PETG has quite a few beneficial properties, especially when it comes to applications such as 3D printing. It comes in a whole range of translucent colors, but here are some of its most common attributes:

Durable – regular PET becomes very hard and brittle when it starts overheating. PETG is also more flexible than ABS and PLA, too. The inclusion of glycol really helps here, making items such as a plastic bottle more comfortable to hold in the hand as well.

Temperature resistant – both minimal shrinkage and warping make it great for printing large objects.

Sticky – PETG is a bit sticky, this means that it would not be good to use it as a support structure for 3D printing models, but its layer adhesion is usually fantastic.

Good chemical resistance – great chemical resistance, with good water, acidic and alkalic resistance.

Tough – PETG is very strong. It’s not brittle, however, it can be easily scratched (more easily than ABS). It also has a high impact resistance, similar to that of polycarbonate.

Amorphous – excellent transparency and high gloss surface (great for artistic print items).

Environmentally friendly – recyclable and food safe. In medical applications, it also stands up to radiation and chemical sterilization techniques without changing color. In short it combines the benefits of PLA (easy to print with) with the benefits of ABS (strong, durable and temperature resistant).

Common applications of PETG

Source: 3devo printed parts with in house made PETG filament (Genius 80M)

PETG is used in a variety of signage, packaging, industrial and medical applications:

- Medical equipment such as braces and pharmaceutical packages

- Protective guards/coatings

- Bottles and food packaging

- Guards and covers for electronic equipment

- Point-of-purchase and graphic displays

Why PETG instead of PLA or ABS?

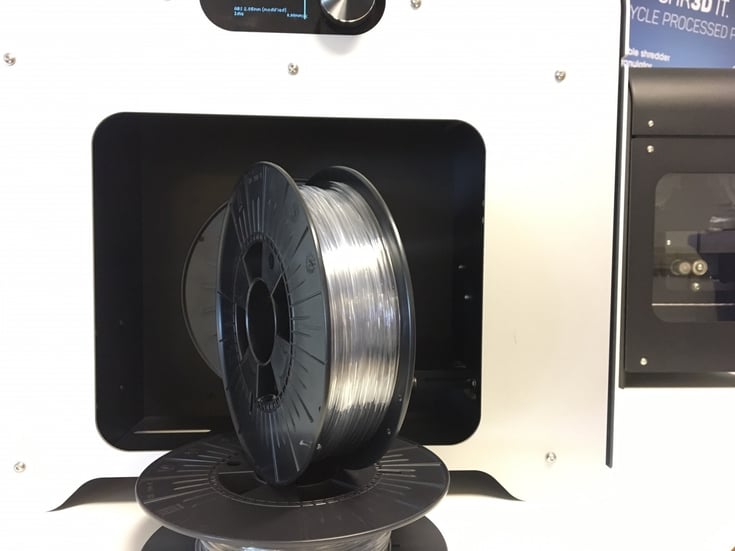

Source: 3devo 2.85mm spool PETG Genius 80M, made on the NEXT 1.0 Advanced Level Extruder

When it comes to printing with PETG, the above characteristics all help making it a great choice. As shown above, extruding a roll is simple, and printing is not too bad either (some users have made this their top choice of filament). We would not recommend printing everything with it as you might not always want your item to be so flexible, but below is a brief summary of how it compares with PLA and ABS.

| PETG | PLA | ABS | |

| Hardness | Very flexible | Not very flexible | R105 to R110 (Harder) |

| Durability | Very flexible | Not very flexible | More flexible |

| Food safe | Food safe | Food safe | Not food safe |

| Heat bed | Heated bed is not a must but it can be an advantage | Doesn’t need a heated bed for 3D printing | Needs a heated bed for 3D printing |

| Price | Slightly more expensive than PLA (+/- 10%) | Average price range | Cheapest of the three |

| Recommended 3D printing temperature | 220 to 250 °C for the hotend | 190-220°C | 230-250°C |

| Recommended print-bed temperature | 50-60°C | 50-70°C | 80-120°C |

Most makers out there say PETG isn’t the easiest to initially print with, as you first have to find that “sweet” spot if you want to create some quality prints.

We at 3devo really enjoy this practical polymer. PETG is very practical and easy of use when it comes to printing, and its combination of rigidity and mechanical properties makes it a great all rounder, perfect for your next 3D-printing idea. Don’t forget to check out our blog for more interesting articles.

Share this

- November 2025 (1)

- October 2025 (1)

- March 2025 (1)

- January 2025 (1)

- December 2024 (2)

- November 2024 (2)

- October 2024 (4)

- September 2024 (2)

- August 2024 (3)

- July 2024 (6)

- June 2024 (3)

- May 2024 (2)

- April 2024 (1)

- March 2024 (1)

- January 2024 (1)

- November 2023 (2)

- October 2023 (5)

- September 2023 (2)

- August 2023 (1)

- July 2023 (1)

- May 2023 (1)

- December 2022 (2)

- June 2022 (1)

- May 2022 (2)

- April 2022 (2)

- March 2022 (6)

- February 2022 (2)

- January 2022 (3)

- December 2021 (3)

- November 2021 (3)

- October 2021 (2)

- September 2021 (3)

- August 2021 (3)

- July 2021 (2)

- June 2021 (1)

- March 2021 (1)

- October 2020 (1)

- June 2020 (1)

- May 2020 (1)

- April 2020 (4)

- November 2019 (1)

- July 2019 (2)

- June 2019 (1)

- May 2019 (1)

- March 2019 (1)

- November 2018 (1)

- September 2018 (1)

- January 2018 (1)

- October 2017 (1)

- September 2017 (1)

- July 2017 (1)

- June 2017 (1)

- May 2017 (1)

- January 2017 (1)

- December 2016 (3)

- November 2016 (2)

- October 2016 (1)

- May 2016 (2)

- August 2015 (2)

- July 2015 (1)