Share this

A Revolution Is Coming With 3D Printed Houses

by 3devo on Jun 21, 2021 10:38:00 AM

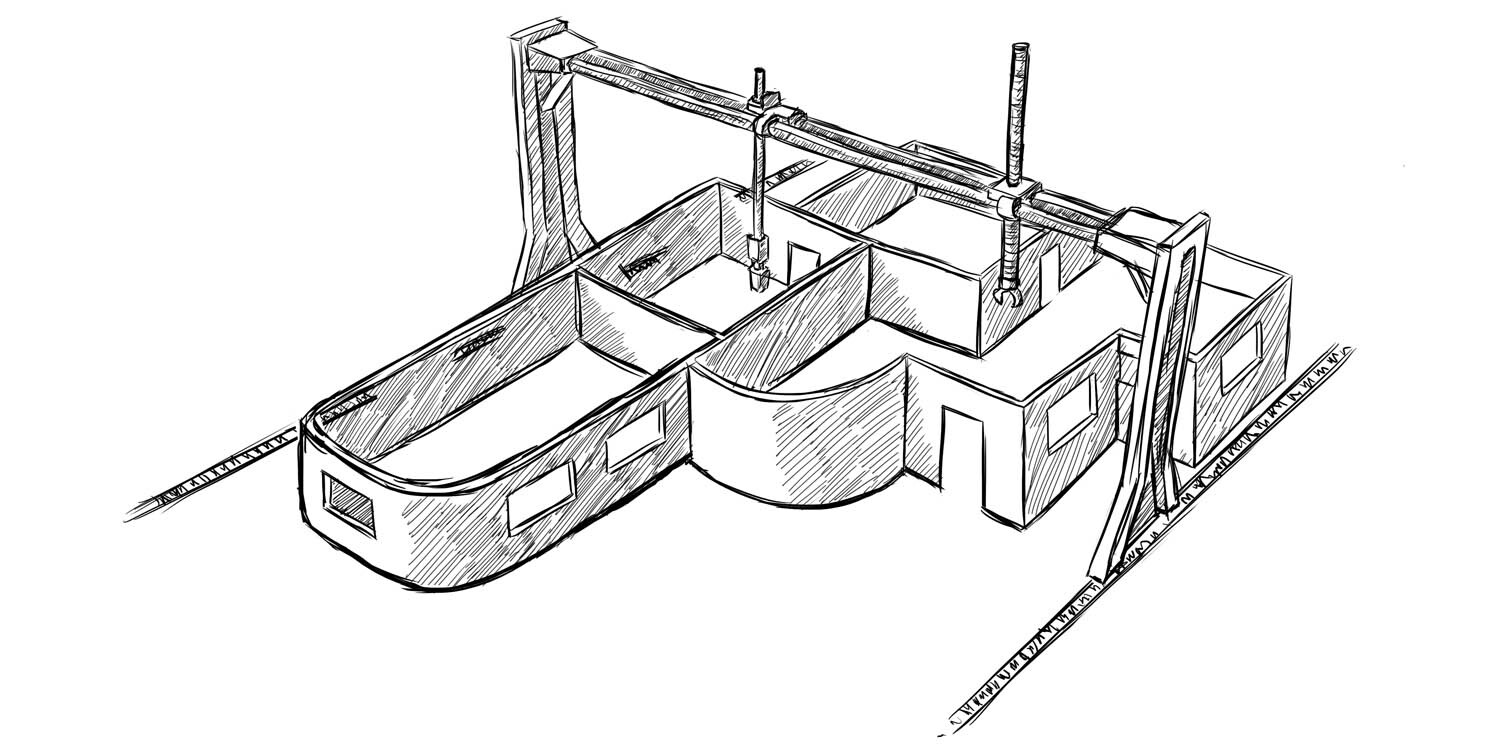

Will 3D printing an entire house be much cheaper and faster when compared to construction techniques used now? That seems to be the promise of this disruptive technology – which is still in its infancy now but evolving rapidly. You can already find 3D-printed houses at far-flung parts of the globe – with pilot projects in Asia, Europe, and the Americas – chances are they could become mainstream by the end of this decade.

What makes 3D-printed houses especially appealing is how you can program almost any customization you can think of into software. As a result, there will soon come a time when you can literally see this entire unique architectural design turn into reality within days, without any human hands directly involved in the construction process and minimal material waste in the process. Other key advantages include:

- The ability to print very fine concrete designs.

- Easy customization.

- Having the possibility of integrating sensors directly during construction itself.

All of the mentioned advantages have resulted in the advent of 3D printed houses.

While this prospect sounds great, some major adjustments are needed because the concept of homes-on-demand still needs to comply with safety and zoning laws – you can’t just plop these 3D-printed houses wherever you wish.

Among key burning issues under review include a focus on environmentally-friendly insulation materials to be used – because recycling of components becomes critical when moving towards a sustainable future. Eindhoven University PDEng candidate, Delaram Zamani, who is researching this topic and playing a role in the 3D-printed housing project pilot, Project Milestone, in Eindhoven, noted: “It’s been quite a challenge finding a material which is sustainable, 3D-printable and has good integration with concrete.” She further adds, “The view is that in the future, one can 3D print both the concrete and insulation material together.”

Zamani got the first-hand experience of intricacies involved in 3D printing and current technical limitations as a former trainee with us. Products of 3D printing can be metal, plastic, polymer, and concrete – made by extrusion (or processing) – but each material is handled separately right now. As technology continues to evolve, she confidently forecasts: “Such technical knowledge and manufacturing systems will soon merge together.”

This is the Holy Grail of 3D house printing which everyone in the construction industry and beyond is looking forward to. “Once you can print multiple materials next to each other, like polymer next to concrete and printing metals in-between, the whole process of 3D-printing houses can be fully automated from start to end with no human intervention needed,” projected Zamani.

Such a prospect is desirable for local authorities and developers worldwide, being under pressure to meet relentless demand for affordable housing, even as they focus on urban renewal with replacement of old buildings and rehabilitating slum areas. “Also, in the case of natural disasters, for example, after earthquakes or flooding, there’s a need for fast construction. That is where 3D-printing construction can help us,” said Zamani.

| Apis Cor 3D Printed this home in 24 hours! (Russia) Image Credits Thrillest |

The 3D Printed Office of The Dubai Future Foundation (UAE) Image Credits ArchDaily |

![]()

| 3D Printed House by ICON & New Story (USA) Image Credits 3DSourced |

Exterior Impression of Project Milestone's five 3D Printed Houses (The Netherlands) Image Credits 3D Printed House |

So what’s next for 3D-printed homes – which have so far popped up in Belgium, China, Germany, India, Russia, Spain, and the United States of America? Beyond private developers, governments are keen – the United Arab Emirates Prime Minister declared back in 2016 that 25% of the buildings in Dubai would be 3D-printed by 2030. And because it is possible to adjust the technology to use whichever suitable construction material is available – even soil and waste organic matter like straw or rice husks – there are already plans for 3D printing viable shelters on Mars!

Looking further into the future, what other potentials could there be for 3D-printed homes? No one knows yet, but here are some possible what-ifs should 3D-house printing technology deliverables surpass today’s expectations:

- Could houses become frequently-replaced consumer items like computers and cars?

- Will it be cheaper to 3D-print a new home instead of doing renovations?

- May leasing, like in many car-buying schemes, replace homeownership?

- Is affording a house no longer a pressing issue for adults, young and old?

Stay tuned; there’s a revolution coming with 3D house printing.

Share this

- March 2025 (1)

- January 2025 (1)

- December 2024 (2)

- November 2024 (3)

- October 2024 (4)

- September 2024 (2)

- August 2024 (3)

- July 2024 (6)

- June 2024 (3)

- May 2024 (2)

- April 2024 (1)

- March 2024 (1)

- January 2024 (1)

- November 2023 (2)

- October 2023 (5)

- September 2023 (2)

- August 2023 (1)

- July 2023 (1)

- May 2023 (1)

- December 2022 (3)

- August 2022 (1)

- June 2022 (1)

- May 2022 (2)

- April 2022 (2)

- March 2022 (7)

- February 2022 (2)

- January 2022 (3)

- December 2021 (3)

- November 2021 (3)

- October 2021 (2)

- September 2021 (3)

- August 2021 (3)

- July 2021 (2)

- June 2021 (1)

- March 2021 (1)

- October 2020 (1)

- June 2020 (1)

- May 2020 (1)

- April 2020 (4)

- November 2019 (1)

- July 2019 (2)

- June 2019 (1)

- May 2019 (1)

- March 2019 (1)

- November 2018 (1)

- September 2018 (1)

- January 2018 (1)

- October 2017 (1)

- September 2017 (1)

- July 2017 (1)

- June 2017 (1)

- May 2017 (1)

- January 2017 (1)

- December 2016 (3)

- November 2016 (2)

- October 2016 (1)

- May 2016 (2)

- August 2015 (2)

- July 2015 (1)