Share this

Filament Maker TWO: The Future of Filament Extrusion

by Ellie Pritchard on Oct 28, 2024 2:39:15 PM

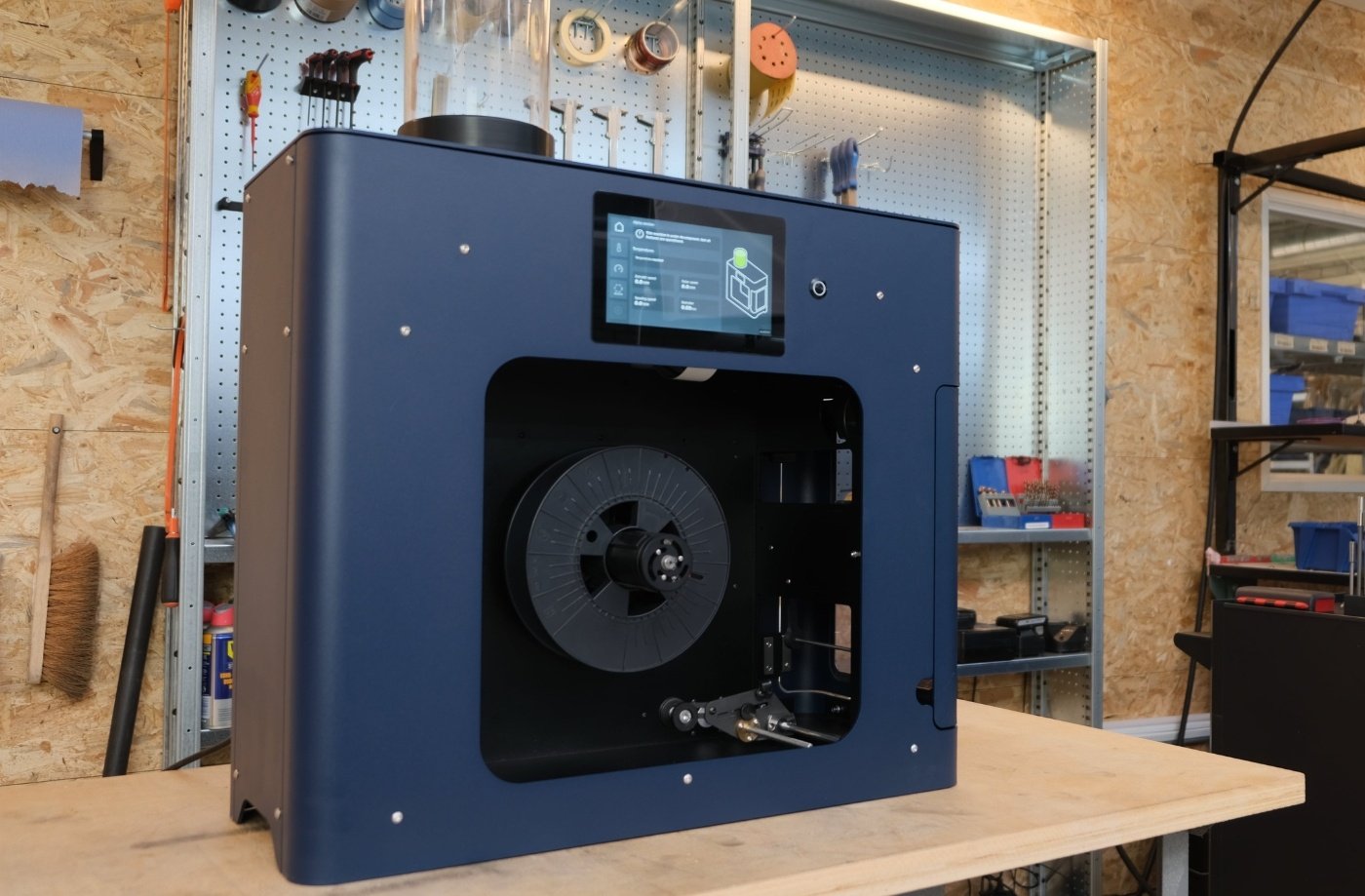

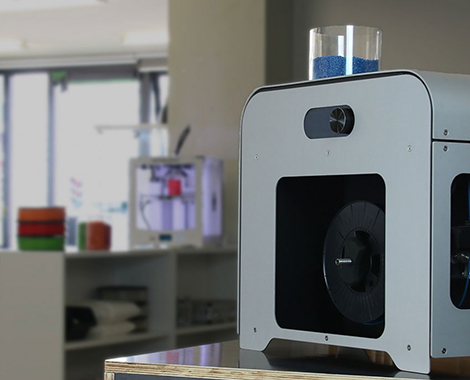

At 3devo, we believe in pushing the boundaries of what’s possible in 3D printing. That’s why we’re thrilled to introduce the Filament Maker TWO, an evolution of our groundbreaking technology that’s set to transform your filament production experience.

With enhanced features and upgrades, the Filament Maker TWO offers unprecedented stability, efficiency, and control. Let’s dive into the standout improvements that make the Filament Maker TWO a game-changer for innovators like you!

Enhanced Extrusion Stability

One of the most significant upgrades in the Filament Maker TWO is its extrusion stability. This improvement stems from three critical changes: a powerful new stepper motor, an efficient gearbox, and a longer extrusion screw. Together, these components work harmoniously to deliver:

- Extremely stable RPM rates: Say goodbye to fluctuations that affect filament quality.

- Five times higher torque: Our new motor outperforms the old DC motor from the Filament Maker ONE, providing the power you need for consistent extrusion.

- More powerful gearbox: Experience a heavier duty gearbox that is more robust and less prone to failure, capable of reaching much higher torque.

With this enhanced stability, you’ll notice a marked improvement in the consistency of your filament, leading to better prints every time.

Longer Extruder Screw for Optimal Performance

The Filament Maker TWO features a longer extruder screw, which is one of the most vital upgrades in this new model. This enhancement provides:

- A more optimal L/D ratio: The longer screw design aims for improved mixing and a more stable flow, enhancing your filament production.

- Potentially higher output: More flights pushing forward the unmelted plastic in the hopper zone ensuring higher output and more stable pressure. So you'll be able to produce more filament in less time, meeting the demands of larger projects without compromising quality.

- Preventing premature melting: The longer screw creates a heat break between the heat zones and the hopper zone which prevents premature melting - this is detremental for keeping the material flow going.

This key feature places the Filament Maker TWO among the top-tier machines on the market, allowing you to explore new applications and materials with confidence.

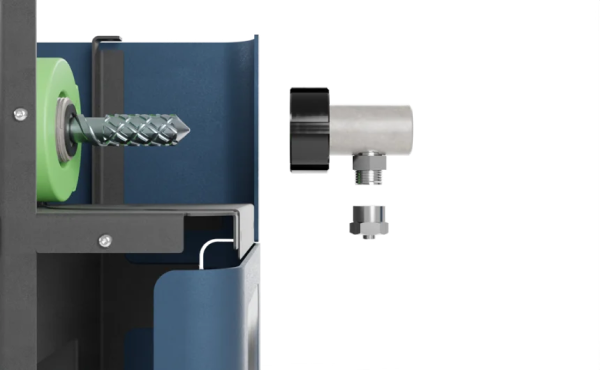

Screw Pull for Hassle-Free Maintenance

Flexibility and efficiency are at the heart of the Filament Maker TWO. With the new screw pull feature, you can now reset and recover quickly without the need to send the machine back for service. This means:

- In-house maintenance: Easily change screws and clean the barrel without any downtime.

- Customization: Install different extruder screws tailored to your specific applications. Plus, thanks to our Custom Product Development service, our R&D team is ready to collaborate with you for unique screw designs, ensuring you get the most out of your machine.

This feature empowers you to maintain control over your production process and adapt to evolving needs.

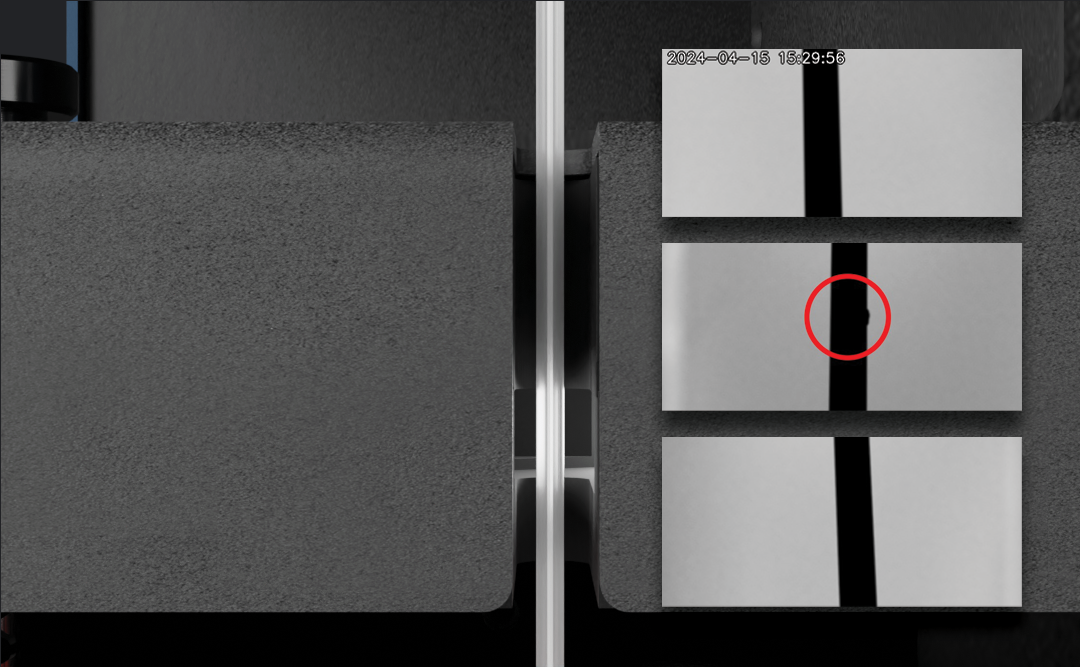

Enhanced Precision with the New Filament Sensor

Say hello to our cutting-edge 3-axis camera sensor, a significant leap forward in filament monitoring. This advanced sensor enables you to:

- Measure ovality with incredible accuracy: Enjoy measurements that are at least five times more accurate than the Filament Maker ONE, ensuring extremely high filament quality.

- Thermal measurement capabilities: Keep a close eye on temperature variations to maintain the ideal conditions for filament production.

- Improved frame rate: Experience continuous monitoring, with no bumps slipping through undetected.

These enhancements offer you unparalleled precision in your filament production, so you can produce consistent, high-quality materials.

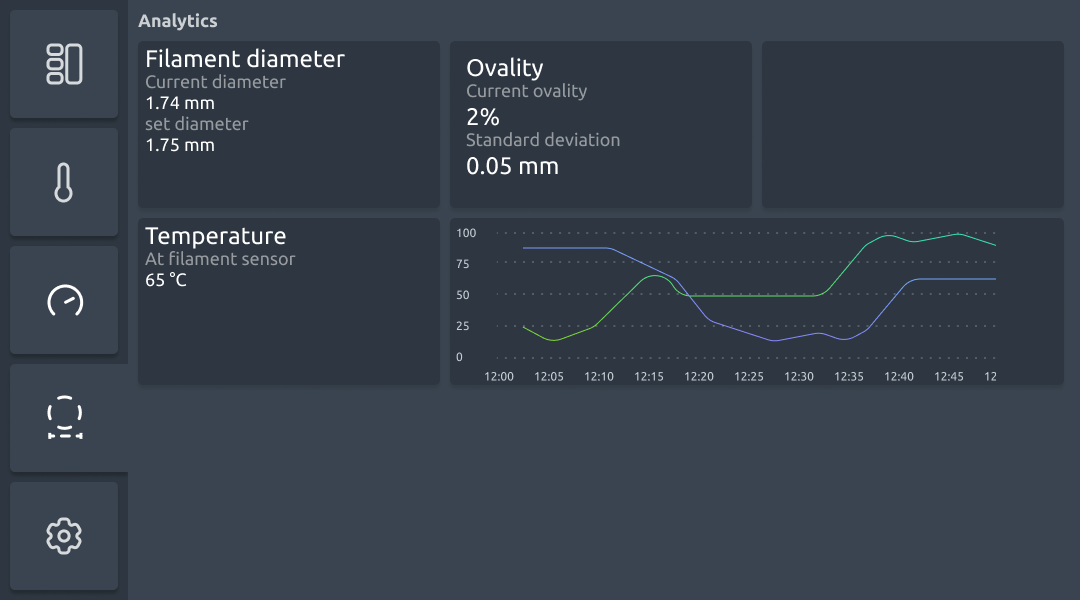

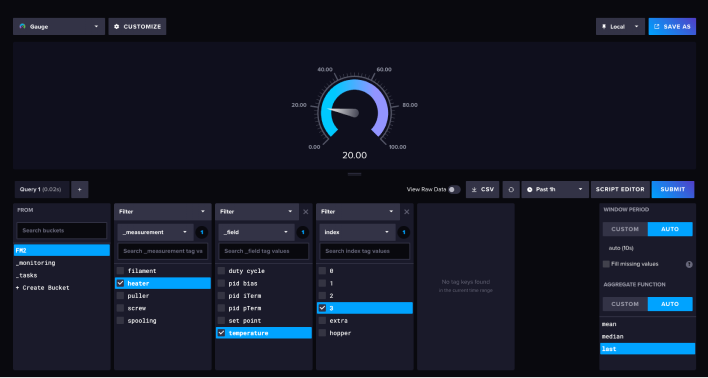

Unprecedented Control with Data Logging & Manipulation

With the Filament Maker TWO, you gain access to an overall improved monitoring system that offers unprecedented control over your extrusion process. Key benefits include:

- Remote monitoring capabilities: Manage the machine from your PC, giving you the freedom to monitor the progress of your filament without being physically present.

- Impressive data logging: Keep track of essential parameters to optimize your production process and make informed decisions.

This level of control is designed to help you streamline operations and maximize efficiency.

Increased Production Rate for Large-Scale Projects

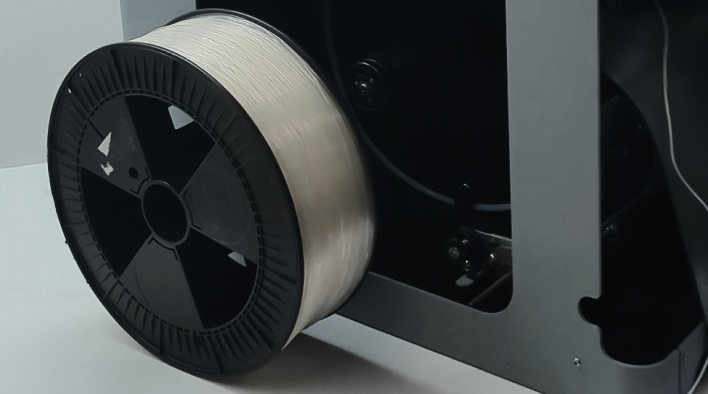

The Filament Maker TWO is engineered for efficiency, allowing you to produce larger 3kg filament spools. With this capability, you can achieve:

- Increased output of up to 1kg/hour: With optional cooling path extensions, you can ramp up production to meet your project demands, making the Filament Maker TWO ideal for larger-scale operations.

Whether you’re scaling up your production or simply looking for improvements in efficiency, the Filament Maker TWO is designed to keep up with your ambitions.

Who Is the Filament Maker TWO For?

The Filament Maker TWO caters to a diverse range of users:

- Upgraders from the Filament Maker ONE: For those hitting the limitations of the Filament Maker ONE, the Filament Maker TWO offers the enhancements you need to elevate your production capabilities.

- Current Filament Maker ONE users: If you're doing well with the Filament Maker ONE but want to achieve even better results, the Filament Maker TWO is your next step forward.

- Prospective users: For those exploring options, the Filament Maker TWO sets a new standard in filament-making technology.

Insights from Our Materials Specialist: Louis Rinaldo

As the most experienced member of our Materials Specialist team, Louis Rinaldo brings over seven years of unparalleled knowledge and expertise in filament extrusion and materials projects. His extensive background at 3devo equips him with a unique perspective on how our technologies can empower customers to achieve their goals. Louis is passionate about helping innovators optimize their processes, and his insights into the Filament Maker TWO’s capabilities highlight the significant benefits that this machine brings to the table. Here’s what he has to say about the most impactful features of the Filament Maker TWO and how they can transform your filament production experience.

Rapid Research for Rapid Prototyping

With the new stepper motor in the Filament Maker TWO, the screw rotation is significantly more stable compared to the previous DC motor design. This stability leads to quicker stabilization of molten material flow, greatly reducing the time spent fine-tuning settings. In traditional setups, optimizing extrusion parameters can take days, but with the Filament Maker TWO, you can streamline this process and accelerate your research and prototyping efforts. This means you can move from concept to prototype faster, giving you the edge in innovation and development.

Customization and Numerous Options

The Filament Maker TWO is designed with the future in mind. It features ports for hardware add-ons, enabling both 3devo-designed and user-created enhancements, thanks to its open-source philosophy. This flexibility means you can customize the machine to meet your specific production needs. Whether you’re looking to modify the hopper or enhance the output side, the Filament Maker TWO allows for co-creation opportunities that empower users to innovate continuously. Additionally, the open-source capabilities extend to data manipulation and remote control from a computer, making it a versatile tool for modern manufacturing. Learn more about these opportunities by checking out our Custom Product Development space.

Enhanced Monitoring for Greater Control

One of the standout features of the Filament Maker TWO is its improved monitoring capabilities. With the integration of a 3-axis camera sensor, you gain unprecedented insights into filament quality. The system collects more data per minute, allowing for automated data manipulation and analysis. If anything goes wrong during production, you’ll be able to spot issues quickly, thanks to this extensive monitoring. Looking ahead, we plan to introduce customizable alarms and warnings to ensure your extrusion process remains stable and produces consistently high-quality results, making the Filament Maker TWO a more production-focused solution compared to its predecessor.

Reduced Downtime for Increased Reliability

The Filament Maker TWO prioritizes efficiency with its design that allows for easy disassembly and cleaning of the extrusion system. This means better access for screw removal and the ability to quickly reset the system if something goes awry. By minimizing downtime, you can maintain productivity levels and enhance long-term reliability. The Filament Maker TWO is built to keep you in action, allowing for smoother operations and less interruption in your production workflow.

Stability and Material-Specific Optimization

The transition to a stepper motor not only stabilizes screw rotation but also enhances flow consistency and output diameter. The Filament Maker TWO allows for fine-tuning of settings tailored to specific materials, ensuring optimal performance. While custom add-ons to further support material processing will be available after launch, the Filament Maker TWO is already designed to provide superior stability, helping you achieve the best results for your unique filament needs.

Larger Spools for Increased Efficiency

With the capability to produce filament spools up to 3kg, the Filament Maker TWO is ideal for larger-scale production. This increased capacity not only improves efficiency but also allows you to keep pace with the demands of your projects, reducing the frequency of spool changes and interruptions in your workflow.

Conclusion

The Filament Maker TWO is more than just a machine; it’s a testament to our commitment to you, our valued partners. Built with your feedback and insights at the forefront, this innovative solution is designed to be your project partner in pushing the boundaries of 3D printing. Whether you’re an industry veteran or just beginning your journey, the Filament Maker TWO equips you with the tools and capabilities to elevate your projects and unleash your creativity.

At 3devo, we genuinely appreciate your input and are excited to see how the Filament Maker TWO will enhance your filament production experience. Together, let’s embark on this exciting journey and explore the future of 3D printing! Your vision is our inspiration, and we can’t wait to support you in bringing it to life.

Discover our new Filament Maker TWO

Learn more about our new FM2 - a powerful filament extruder and filament research platform in one machine.

Frequently Asked Questions (FAQs)

The Filament Maker TWO allows for rapid research and prototyping with stable RPM rates, easy customization with open-source add-ons, and extensive monitoring capabilities for better data analysis and control over the extrusion process.

Yes! The FM2 is designed with customization in mind, allowing you to adjust settings for specific materials and explore unique screw designs through our collaboration with the R&D department.

The Filament Maker TWO is engineered for easy disassembly and cleaning, minimizing downtime. Routine maintenance involves cleaning the extrusion system and checking for any necessary adjustments based on your production needs.

The Filament Maker TWO can produce filament spools of up to 3kg, making it ideal for larger-scale production and reducing the frequency of spool changes during projects.

The advanced monitoring system includes a 3-axis camera sensor for precise filament analysis, increased data collection for better insights, and future plans for customizable alarms and warnings to maintain production quality and stability.

Begin Your Journey Towards Sustainable 3D Printing

Start by transforming plastic waste into recyclable material with our efficient and innovative shredder, designed to empower your filament recycling journey.

.jpg?width=865&height=500&name=GP20-Shredder-Hybrid-1%20(2).jpg)

Explore More on Sustainable 3D Printing Materials

Recycle Plastic Waste

Transform plastic waste into quality 3D printing filament and join our mission for responsible innovation with 3devo's complete recycling solution.

%20-%20instasize.png?width=800&height=640&name=which-plastics-are-recyclable%20(1)%20-%20instasize.png)

Which Plastics are recyclable?

Understand different plastic types and their recyclability to make informed decisions on selecting the right material for your needs.

%20-%20instasize%20(1).png?width=800&height=640&name=PETG-e1494958102567%20(1)%20-%20instasize%20(1).png)

How to recycle PET into Filament?

Discover how PET plastic is transformed into eco-friendly 3D printing filaments on our dedicated Recycling PET page.

Share this

- March 2025 (1)

- January 2025 (1)

- December 2024 (2)

- November 2024 (3)

- October 2024 (4)

- September 2024 (2)

- August 2024 (3)

- July 2024 (6)

- June 2024 (3)

- May 2024 (2)

- April 2024 (1)

- March 2024 (1)

- January 2024 (1)

- November 2023 (2)

- October 2023 (5)

- September 2023 (2)

- August 2023 (1)

- July 2023 (1)

- May 2023 (1)

- December 2022 (3)

- August 2022 (1)

- June 2022 (1)

- May 2022 (2)

- April 2022 (2)

- March 2022 (7)

- February 2022 (2)

- January 2022 (3)

- December 2021 (3)

- November 2021 (3)

- October 2021 (2)

- September 2021 (3)

- August 2021 (3)

- July 2021 (2)

- June 2021 (1)

- March 2021 (1)

- October 2020 (1)

- June 2020 (1)

- May 2020 (1)

- April 2020 (4)

- November 2019 (1)

- July 2019 (2)

- June 2019 (1)

- May 2019 (1)

- March 2019 (1)

- November 2018 (1)

- September 2018 (1)

- January 2018 (1)

- October 2017 (1)

- September 2017 (1)

- July 2017 (1)

- June 2017 (1)

- May 2017 (1)

- January 2017 (1)

- December 2016 (3)

- November 2016 (2)

- October 2016 (1)

- May 2016 (2)

- August 2015 (2)

- July 2015 (1)