Share this

Reducing Plastic Consumption With Lunar Powder

by 3devo on Oct 27, 2020 12:43:00 PM

Since becoming a part of the European Astronaut Centre’s lab equipment in February 2017, the Composer 450 has been instrumental in their prototyping processes. ESA researchers have successfully used the extruder to develop custom quantities of PLA-based filament for research and development iterations. The 3devo set-up gives Spaceship EAC the ability to create 3D printing filament in-house. Also, reducing Spaceship EAC’s dependence on the expertise and availability of third-party filament suppliers.

What’s happening now? Going green (into space)

With ESA’s well-equipped 3devo set-up, they have taken full advantage of the machine’s capabilities – leading them to their latest discovery. For long missions in space, astronauts need self-reliant tools to be able to manufacture parts and structures. An additive manufacturing process such as FDM is ideal for this application, thanks to its flexibility and efficient material usage. Seems ideal, right? Unfortunately, there is a catch. FDM requires large amounts of plastic to create 3D parts – costing the agency time and money since materials must be sent from Earth.

With the initiative of ESA’s Spaceship EAC, materials engineer trainee, Benoît Andre, was assigned to find a new material that would reduce costs and minimize plastic sent into space. The answer he unveiled was the usage of the moon’s resources. Benoît commenced a world premiere by creating a composite material from a PLA/Lunar powder mixture for FDM printing.

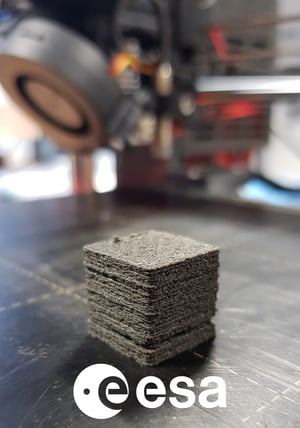

“In practice, I used the 3devo filament maker to produce a printable filament, using only PLA pellets and regolith simulant (EAC-1) as feedstock material. EAC-1 is a sand-like mineral powder developed by spaceship EAC to mimic the properties of lunar regolith. The filament maker was used to mix the feedstock materials, melt the PLA pellets, and finally extrude the composite filament, all in a single continuous step. By optimizing the parameters, I was able to produce homogenous filaments with various regolith concentrations. Several parts have been successfully 3D-printed using this filament and a slightly modified commercial FDM printer (Prusa Mk3s).” – Benoît Andre, Materials Engineer Trainee, EAC – European Space Agency

From theory to reality

Benoît’s objective was to find a solution for reducing plastic consumption on the moon. This objective led him to create a composite material made up of PLA and lunar powder, the regolith, to produce 3D printing filament. This new material will decrease the volume of plastic inside a 3D printed object while maintaining the mechanical properties necessary for resistant parts. Now, ESA will not have to compromise between an easy manufacturing process with a high printability and good mechanical properties with this new material.

“The real-time data provided by the filament maker (e.g., temperatures, speeds, diameter) were used throughout this study to understand and improve the manufacturing process. The filament, as well as printed sample parts, were analyzed through a battery of laboratory tests.” – Benoît Andre, Materials Engineer Trainee, EAC – European Space Agency

This study enabled Benoît to show the feasibility of FDM printing using a PLA/regolith composite and better understand the principles, advantages, and drawbacks through this process. By pushing the process and the filament maker to its limits, the end-goal will produce highly concentrated filaments within space and successfully 3D-print various parts.

To follow this exciting journey all the way to the moon click here.

Share this

- March 2025 (1)

- January 2025 (1)

- December 2024 (2)

- November 2024 (3)

- October 2024 (4)

- September 2024 (2)

- August 2024 (3)

- July 2024 (6)

- June 2024 (3)

- May 2024 (2)

- April 2024 (1)

- March 2024 (1)

- January 2024 (1)

- November 2023 (2)

- October 2023 (5)

- September 2023 (2)

- August 2023 (1)

- July 2023 (1)

- May 2023 (1)

- December 2022 (3)

- August 2022 (1)

- June 2022 (1)

- May 2022 (2)

- April 2022 (2)

- March 2022 (7)

- February 2022 (2)

- January 2022 (3)

- December 2021 (3)

- November 2021 (3)

- October 2021 (2)

- September 2021 (3)

- August 2021 (3)

- July 2021 (2)

- June 2021 (1)

- March 2021 (1)

- October 2020 (1)

- June 2020 (1)

- May 2020 (1)

- April 2020 (4)

- November 2019 (1)

- July 2019 (2)

- June 2019 (1)

- May 2019 (1)

- March 2019 (1)

- November 2018 (1)

- September 2018 (1)

- January 2018 (1)

- October 2017 (1)

- September 2017 (1)

- July 2017 (1)

- June 2017 (1)

- May 2017 (1)

- January 2017 (1)

- December 2016 (3)

- November 2016 (2)

- October 2016 (1)

- May 2016 (2)

- August 2015 (2)

- July 2015 (1)