Share this

Carbon Fiber Filament is Transforming 3D Printing

by 3devo on Nov 25, 2021 3:52:00 PM

Carbon fiber is a new–age material that has found diverse applications in the automotive, aerospace and military sectors. The benefits of carbon fiber in composites (adding strength, stiffness, heat resistance and durability) combined with its ease to be used in 3D printing make it an increasingly popular structural material. Indeed, growing interest in cost-effective, 3D–printed automotive and aerospace products has made carbon fiber filament a prolific research area. This blog will take you through the all the details you’ll need to know about carbon fiber 3D printing, including the different types, advantages, and challenges.

The Rise of Composite 3D Printing

More companies are 3D printing composites to make parts (via 3DNatives)

More companies are 3D printing composites to make parts (via 3DNatives)

The 3D printing market is likely to expand to a whopping USD 180-490 billion by the year 2025. This is not surprising, given that 3D printing offers an unprecedented flexibility in component design that conventional techniques simply cannot. However, the commercial applicability of a 3D printing technique relies heavily on the materials with which it can work.

Composite materials offer cheaper, lighter and 3D-printable alternatives to heavy and expensive engineering materials such as metals like aluminum. A common class of composite materials includes thermoplastic polymeric materials reinforced with fibers.

Fibers commonly used as reinforcing fillers in composites with thermoplastic base materials include carbon fiber, fiberglass and Kevlar®. Composite 3D printing is an exciting though relatively new area that is fast becoming popular. One of the reasons for its rising recognition is carbon fiber and the many advantages it has to offer.

What is Carbon Fiber?

Carbon fibers are essentially long chains of carbon atoms around 5-10 microns in diameter. They are lightweight, but have high mechanical strength, thermal tolerance and chemical resistance. These properties make them suitable for use as reinforcement materials in the automotive, aerospace, construction and military sectors. Compared to other fibers, carbon fiber offers the highest flexural strength of over 540 MPa and the highest strength-to-weight ratio.

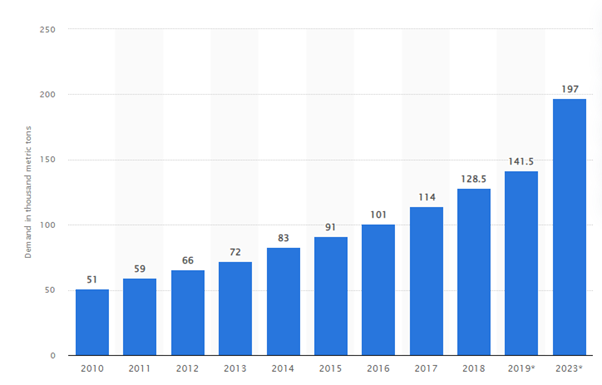

Carbon fiber’s growing interest in cost-effective, 3D-printed automotive and aerospace products has helped increase its overall demand, as shown below.

The Demand for Carbon Fiber Reinforced Plastics Globally (via Statista, 2021)

The Demand for Carbon Fiber Reinforced Plastics Globally (via Statista, 2021)

Over 90% of the carbon fiber in the world comes from the pyrolysis of polyacrylonitrile. The carbon fiber thus produced is either used as a continuous fiber, chopped into smaller fragments, or milled. The form of carbon fiber used depends upon its intended application. For example, short carbon fibers, less than 1mm in length, find use in reinforced filaments for composite 3D printing.

3D Printing Carbon Fiber

Carbon fiber can be 3D-printed in two primary ways:

- Reinforced with carbon fibers (Chopper Fibers) – As we know, mixing carbon fibers with polymeric materials enhances the mechanical strength of the resulting composites.

- Continuous carbon fibers (CFF) – The other way is using continuous carbon fiber-reinforced composite filaments, which have a higher mechanical strength compared to short carbon fiber composite filaments.

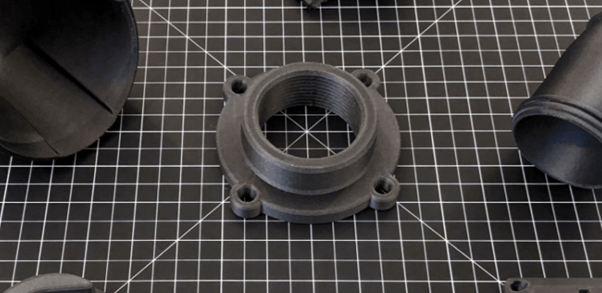

Makerbot 3D Printed Nylon 12 Carbon Fiber Part (via MatterHackers)

Makerbot 3D Printed Nylon 12 Carbon Fiber Part (via MatterHackers)

Overcoming the Challenges of 3D Printing Carbon Fiber Filament

The use of carbon fiber reinforcement in 3D printing is not without its challenges. Take these three problem (and solution) examples so you know what you can expect when 3D printing carbon fiber.

Problem #1 – Continuous carbon fiber 3D printing requires specialized nozzles and fiber-cutting systems

Solution – Using plastic filaments reinforced with short carbon fibers work very well even with general purpose 3D printers. Thus, there is no need to have a dedicated 3D printer for printing short carbon fiber-reinforced composite filaments.

Problem #2 – Clogging the nozzles of the 3D Printer

The fibers get entangled and misaligned, making the molten filament more viscous and more prone to clogging the nozzle.

Solution – Thankfully, this issue is easily resolved with the help of hardened steel nozzles which do not clog as frequently. We also recommend the use of hardened steel nozzles as they are resistant to the abrasive properties of carbon fiber.

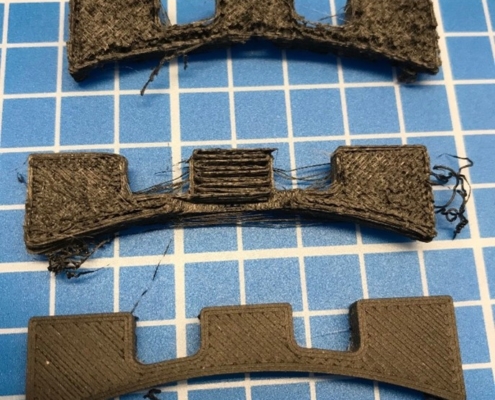

Problem #3 – Poor surface finish in the final product

You might experience a rough surface finish due to an access of carbon fibers in the filament.

Solution – Ultrasound- and plasma-laser-based techniques have allowed an improvement in the surface profile of 3D-printed carbon fiber composites. At the same time, resolving some of the other challenges in the field will require more scientific research.

For example, 3D-printing carbon fiber filaments can lead to the formation of micro voids in the fibers. Another example is the formation of meso voids between different bundles of carbon fibers in the 3D printing filament.

Issues faced when printing Carbon Fiber (via Limey39 on Hubs)

Issues faced when printing Carbon Fiber (via Limey39 on Hubs)

Commercially Available Carbon Fiber Products

Despite some persisting challenges, carbon fiber filaments find extensive use on a commercial scale. Today, carbon fiber reinforced filaments are easily available for purchase from various vendors.

Markforged has their own custom-designed 3D printing filament called, Onyx™. This filament is a composite of micro carbon fiber and nylon, boasting of high design accuracy and good-quality surface finish.

Markforged Onyx - Micro carbon fiber filled nylon for 3D Printing (via Markforged)

Markforged Onyx - Micro carbon fiber filled nylon for 3D Printing (via Markforged)

American-Israeli 3D printer manufacturer Stratasys also offers a composite of carbon fiber and nylon 12 as the base polymer material.

In fact, so universal is the commercial availability of filaments today that one can order Nylon-carbon fiber filaments off Amazon.

The Future of 3D Printing with Carbon Fiber

Carbon fiber-reinforced composite filaments have heralded a new era of additive manufacturing. This is an era in which the low cost and light weight of 3D-printed materials complement their high mechanical strength. Of course, there are some challenges along the way, but current research focuses heavily on overcoming them. The commercial availability of several polymer-carbon fiber composite filaments also shows industrial support for these new-age structural materials.

With the ever-increasing demand for impactful and cost-effective 3D printing applications, the future of carbon fiber filaments is impeccably bright.

We have just released some key findings and challenges we encountered when extruding Carbon Fiber Filament, read more to see how we overcame them!

Unleash the Potential of Carbon Fiber Filament with our Filament Maker

Level up your 3D printing game with our Carbon Fiber Filament Maker! Create strong and lightweight carbon fiber composites for automotive, aerospace, and beyond. Say goodbye to clogs and surface imperfections - our filament maker delivers top-notch carbon fiber filament for flawless 3D printing!

Share this

- November 2025 (1)

- October 2025 (1)

- March 2025 (1)

- January 2025 (1)

- December 2024 (2)

- November 2024 (2)

- October 2024 (4)

- September 2024 (2)

- August 2024 (3)

- July 2024 (6)

- June 2024 (3)

- May 2024 (2)

- April 2024 (1)

- March 2024 (1)

- January 2024 (1)

- November 2023 (2)

- October 2023 (5)

- September 2023 (2)

- August 2023 (1)

- July 2023 (1)

- May 2023 (1)

- December 2022 (2)

- June 2022 (1)

- May 2022 (2)

- April 2022 (2)

- March 2022 (6)

- February 2022 (2)

- January 2022 (3)

- December 2021 (3)

- November 2021 (3)

- October 2021 (2)

- September 2021 (3)

- August 2021 (3)

- July 2021 (2)

- June 2021 (1)

- March 2021 (1)

- October 2020 (1)

- June 2020 (1)

- May 2020 (1)

- April 2020 (4)

- November 2019 (1)

- July 2019 (2)

- June 2019 (1)

- May 2019 (1)

- March 2019 (1)

- November 2018 (1)

- September 2018 (1)

- January 2018 (1)

- October 2017 (1)

- September 2017 (1)

- July 2017 (1)

- June 2017 (1)

- May 2017 (1)

- January 2017 (1)

- December 2016 (3)

- November 2016 (2)

- October 2016 (1)

- May 2016 (2)

- August 2015 (2)

- July 2015 (1)