Share this

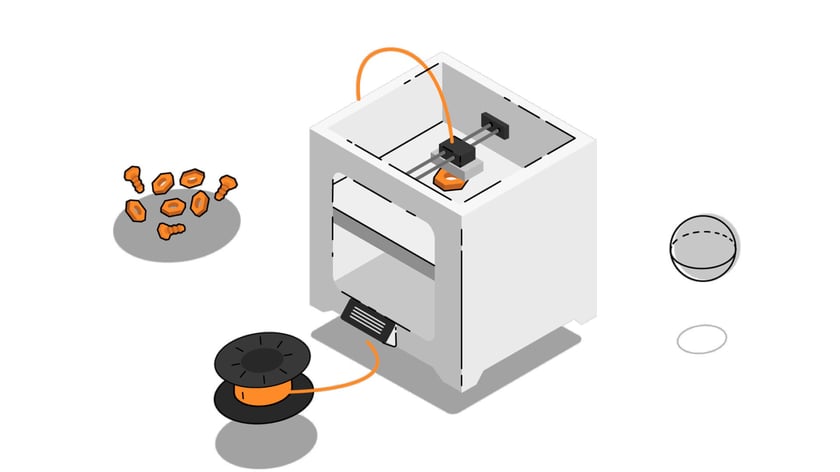

3D printing With Recycled Filament

by 3devo on May 7, 2020 4:06:00 PM

The final step in our recycling journey is here…it’s time to 3D print with the filament we extruded from our plastic recycled waste.

We must say it has been a very exciting journey! We’ve learned which plastic materials are and aren’t recyclable, how to shred our plastic waste, how to extrude our plastic waste into filament and now finally how we can 3D print with the filament we made.

If you missed any of the previous blog posts, we recommend you checking them out first before continuing on with this one, as each blog post is an important step to get to this final step of 3D printing.

If you are not aware of what an (FDM) 3D printing machine is or if you would like to learn more about it, you can check our blog post out where we guide you through FDM 3D printing.

How To Get Started

Testing Phase

Now that you have your filament, we recommend that you first use a spool with a small amount of the filament on. Since you extruded filament from recycled plastics, it’s possible that the plastic material will not react the same way as you are used to. Therefore, it’s better to start with a small print before diving into the actual print you want to create.

Filament Texture

Before you start 3D printing, it is important to first check your filament texture out. Your filament needs to have an even consistency and it needs to have a round texture. If your filament does not have the same texture all over, we recommend you to go one step back and to reproduce your filament. Perhaps our previous video can help, where our material expert, Timo, explains how you can extrude filament perfectly.

Experiment Phase

Keep in mind that 3D printing is an experimental process just like extruding filament. Like we mentioned previously, “don’t be too harsh on yourself when you don’t extrude the perfect filament right away!”. In this case, don’t be too harsh on yourself when you don’t print the perfect 3D print right away! Just be patient and have some fun with it.

Temperature & Printing Settings

Make sure that you have the right temperature and printing settings. Each plastic material reacts differently to heat, if you for example; have a too high-temperature setting, your filament will tend to melt too quickly which will cause your 3D print to not look evenly everywhere. We recommend you to first find the right settings on the internet, our material experts do so too when printing with new material. If you are new to 3D printing, no worries, PinShape has created a guide for beginners in which they give you all the right base settings.

Now that you know all the things you should do to get started, you can start 3D printing! If you make a print and you share it on social media, make sure to tag us as we love to see your creations.

Thank you for being part of this journey, we hope that you learned as much as we did. If you have any questions, don’t hesitate to contact us, we love hearing back from you!

We hope to see you back on another journey.

Share this

- November 2025 (1)

- October 2025 (1)

- March 2025 (1)

- January 2025 (1)

- December 2024 (2)

- November 2024 (2)

- October 2024 (4)

- September 2024 (2)

- August 2024 (3)

- July 2024 (6)

- June 2024 (3)

- May 2024 (2)

- April 2024 (1)

- March 2024 (1)

- January 2024 (1)

- November 2023 (2)

- October 2023 (5)

- September 2023 (2)

- August 2023 (1)

- July 2023 (1)

- May 2023 (1)

- December 2022 (2)

- June 2022 (1)

- May 2022 (2)

- April 2022 (2)

- March 2022 (6)

- February 2022 (2)

- January 2022 (3)

- December 2021 (3)

- November 2021 (3)

- October 2021 (2)

- September 2021 (3)

- August 2021 (3)

- July 2021 (2)

- June 2021 (1)

- March 2021 (1)

- October 2020 (1)

- June 2020 (1)

- May 2020 (1)

- April 2020 (4)

- November 2019 (1)

- July 2019 (2)

- June 2019 (1)

- May 2019 (1)

- March 2019 (1)

- November 2018 (1)

- September 2018 (1)

- January 2018 (1)

- October 2017 (1)

- September 2017 (1)

- July 2017 (1)

- June 2017 (1)

- May 2017 (1)

- January 2017 (1)

- December 2016 (3)

- November 2016 (2)

- October 2016 (1)

- May 2016 (2)

- August 2015 (2)

- July 2015 (1)