Share this

What is the Future of 3D Printer Filament

by 3devo on Mar 3, 2022 9:42:00 AM

You may find yourself standing over a cold 3D printer asking questions “How can I make my 3D models stand out more?” or even “What is the meaning of filament?”. Well, we have some news for you. You are not alone.

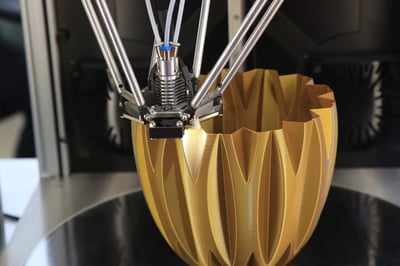

Filament is the lifeblood of most 3D printers. Without it, you couldn’t print your designs.

Once you have an understanding of the basics of filament, keeping up to date with the latest innovations and trends in 3D printing and filament technology will help you continue to improve your craft. Increasing your capabilities allows you to make more with less and produce prints that were previously out of your reach.

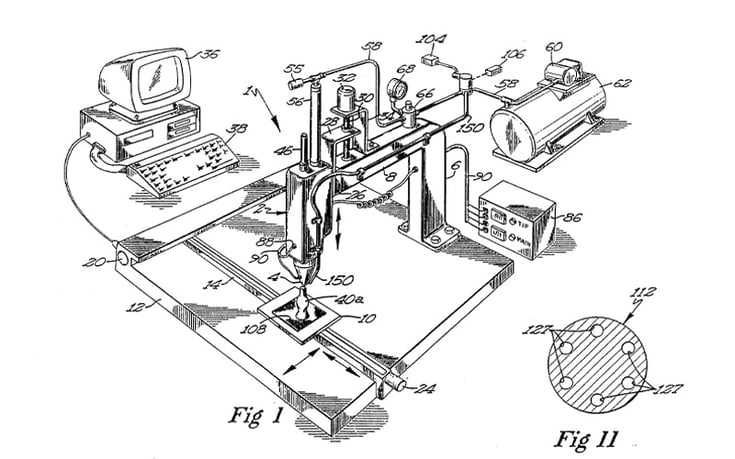

Patent Drawing for First 3D Printer Patent. 3D Printing Filament has come a long way since its first applications in the early 80’s – from primarily being made of single use resins to the re-formable, highly durable plastics used today.

One thing is certain, the filaments used in 3D printing will continue to evolve. The best makers know the …

Top Trends in 3D Printer Filament

- Improvements in 3D Printing Technology

- Increased Variety of Exotic Blend Filament

- Powdered Materials for Custom Blends

- Experimental and Optimized Filaments

- Custom Filament Colors

- Recycled Materials in Filament

- Plant Based, Sustainable Filament

- Spool-less Filament Rolls

1. 3D Printing is Becoming More Affordable

With printers becoming less expensive and more efficient, small businesses and startups are getting their own 3D printing setups to increase the speed of product development. New types of businesses are utilizing this technology for different applications as well.

Though we aren’t past the “Should I Buy a 3D Printer” stage, the industry has developed greatly in recent years. More printers on maker’s desks means more projects will be printed and more filament will be used.

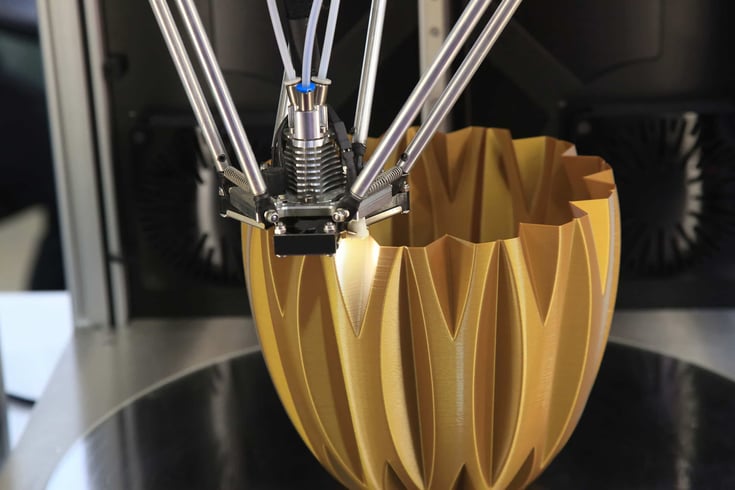

2. Exotic Blends Are Friends

Filament blends allow you to create the right look and physical properties for your 3D printing project. If “Exotic Materials” sound exciting to you, it’s because they are. Here are some of the hottest blends out:

- Wood – looks great with its natural tones and can even transfer the scent of the donating tree.

- Metal – strong, heavy and sleek. Using it can also make your prints magnetic and carry an electrical charge or signal.

- Minerals – such as sandstone, glass and gemstones can be added to create different textures, finishes and other properties to the filament.

Exotic materials such as wood and metal are being used to generate specific properties in filament.

3. Powders Mix Better (than granulate)

Though it takes more time to produce, powdered feed stock mixes more uniformly for complex filament formulations. As new material blends are created, powdered feed material is getting a respectable place in filament production.

Specifically, higher concentrations of metals and exotic materials can be mixed when using powders and the filament consistency is much higher for complex blends.

4. Experiment and Control

Different projects have different requirements. While 3D printing is now established enough for commercial use, it is still at a stage where improvements can be made to filaments.

You can come up with your own formulations for best results which is very helpful in the prototype stage. By testing the attributes of different filament blends and logging the results, you can optimize your filament to suit specific project needs. Get your calculator out!

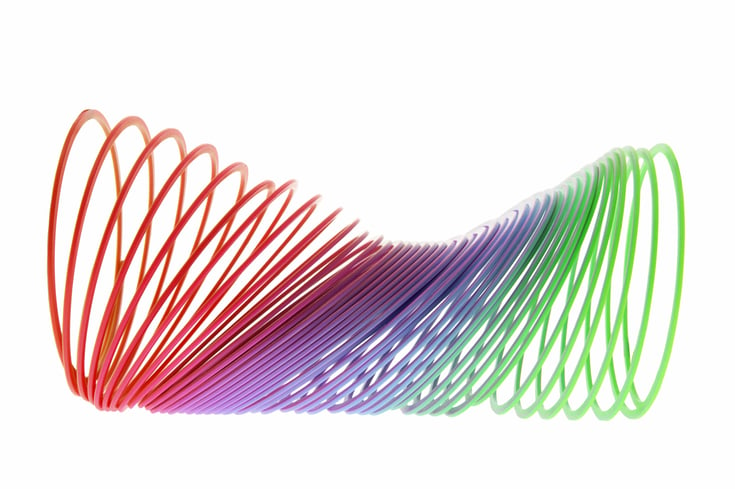

5. Customized Filament Colors

Variety is the spice of life. Having a wide array of colors to choose from is great help in making a vivid 3D print. In the past, there weren’t as many color options available for printer filament.

Sometimes, the color has to be exact. Makers are now creating their own custom filament colors to match branding or visual requirements for their clients and project requirements.

There are even companies like colorFabb that can create a vast range of filament colors for you to use on your 3D printing project.

No longer stuck with a handful of options, 3D Printer Filaments Colors can be customized to project needs.

6. Time to Recycle

With the cost of quality filament extruding equipment coming down, it is easier than ever to make your own custom blend of filament to fit your project’s needs, including strength, appearance.

You can now recycle your existing models, print waste and even plastic bottles by first breaking it up, grinding it down, and then granulating it to a consistent size. Then you can take that granulate and form filament with an extruder.

7. Made From Sustainable Materials

Some may say that our environment has seen better days. Filaments made from PLAs (polylactic acid) use a plant based plastic that is biodegradable.

These new filaments made from plants, called bio-plastics or biopolymers, are sustainable and less likely to clog up landfills as they break down naturally over time.

3D Printing Filaments can be made from sustainable, plant-based plastics

8. Too Cool for Spools

Filament spools are heavy to ship and create a lot of waste for busy printers.

Recently, there has been a push to remove the spool from filament rolls. Look out for MakerSpool, a printable spool to load spool-less filament stock onto for

the feed cycle.

A lot of makers are extruding their own material around used filament spools, saving the need for shipping and disposing of print waste.

Future of Filament – Now You Know

Now that you know all the latest trends and innovation in the world of 3D Printing Filament Technology, perhaps you will incorporate it into your next project or streamline your materials sourcing.

At 3devo, we’re just getting started. Make sure to subscribe to our social media to keep up to date with everything 3D Printing.

Want to learn more about how filaments could be used? Read all about it in our whitepaper by clicking the button below:

Share this

- November 2025 (1)

- October 2025 (1)

- March 2025 (1)

- January 2025 (1)

- December 2024 (2)

- November 2024 (2)

- October 2024 (4)

- September 2024 (2)

- August 2024 (3)

- July 2024 (6)

- June 2024 (3)

- May 2024 (2)

- April 2024 (1)

- March 2024 (1)

- January 2024 (1)

- November 2023 (2)

- October 2023 (5)

- September 2023 (2)

- August 2023 (1)

- July 2023 (1)

- May 2023 (1)

- December 2022 (2)

- June 2022 (1)

- May 2022 (2)

- April 2022 (2)

- March 2022 (6)

- February 2022 (2)

- January 2022 (3)

- December 2021 (3)

- November 2021 (3)

- October 2021 (2)

- September 2021 (3)

- August 2021 (3)

- July 2021 (2)

- June 2021 (1)

- March 2021 (1)

- October 2020 (1)

- June 2020 (1)

- May 2020 (1)

- April 2020 (4)

- November 2019 (1)

- July 2019 (2)

- June 2019 (1)

- May 2019 (1)

- March 2019 (1)

- November 2018 (1)

- September 2018 (1)

- January 2018 (1)

- October 2017 (1)

- September 2017 (1)

- July 2017 (1)

- June 2017 (1)

- May 2017 (1)

- January 2017 (1)

- December 2016 (3)

- November 2016 (2)

- October 2016 (1)

- May 2016 (2)

- August 2015 (2)

- July 2015 (1)