Share this

PEI - Extruding The High-Performance Polymer

by 3devo on Oct 25, 2017 11:30:00 AM

PEI, Polyetherimide, is one of the more rare polymers we have tested here at 3devo. That, however, does not mean it is any less useful. This high performance engineering thermoplastic, usually with an amber to transparent colour, makes a great name for itself in various high-demanding applications. It can often replace metal or other strong substances thanks to its impressive chemical and mechanical properties, but how well does it extrude? In this article we will make a brief overview of PEI as well as our extrusion tests for this strong polymer.

Filament Summary

PEI’s characteristics include extreme rigidity, high strength (even at elevated temperatures), long term heat resistance, dimensional stability and good electrical properties. It is easy to spot due to its light amber colour (unfilled) and is usually semi-transparent. Like other amorphous, high temperature resins, PEI has outstanding dimensional stability and is inherently flame retardant.

PEI does resist chemicals, such as hydrocarbons, alcohols and halogenated solvents. Creep resistance over the long term allows PEI to replace metal and other materials in many structural applications. It is also widely used in electronics because of its good arc resistance and dielectric constant. Furhermore, PEI is UFDA/USDA and USP class VI compliant.

Applications

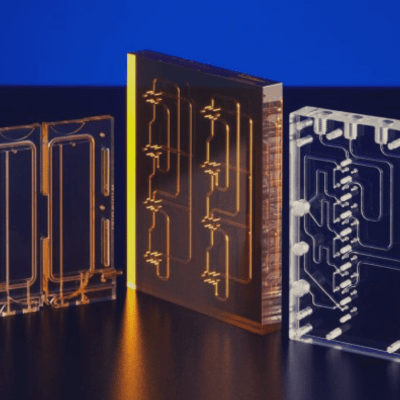

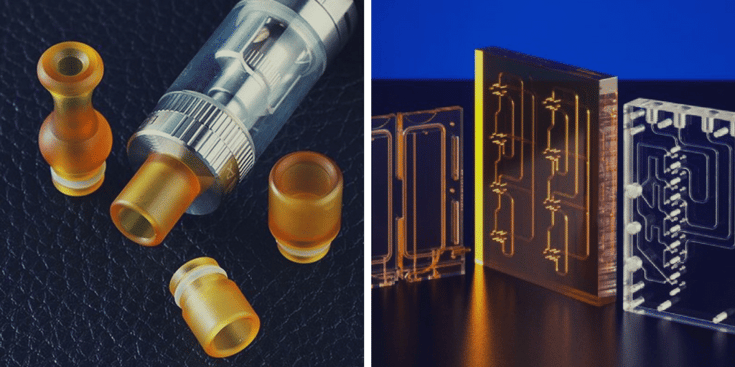

PEI used in vape mouthpieces (left) to plastic manifolds (right) via Carville Plastics

- Reusable machined components

- Aircraft/Automotive instrumentation

- Plastic Manifolds

- Electrical insulators

- Electrical component housings

Advantages

- Great thermal stability (continuous use temperature of 365F/180° C)

- High strength

- Continuous rigidity and strength to 340F (170°C)

- Dimensionally stable

- Excellent flame and heat resistance (UL 94 V-0 rated)

- Consistent dielectric properties over a range of frequencies

- Good acid resistance

- High resistance to autoclave sanitizing

- Low moisture absorption

- Can withstand steam autoclaving

- Inherently flame retardant

- Certified Grades for food-contact and bio-compatibility applications

Disadvantages

- Can be expensive

- Not a lot of colour choices (amber or sometimes transparent)

Extruding PEI (ULTEM 1010 Resin)

Here at 3devo we were able to acquire some PEI for extrusion tests (Ultem 1010 Resin was used). Because of its high strength factors we were interested to see what the results would be. Below is an overview of the whole process, however, for a more detailed report please contact us via the sales contact page.

Preparation

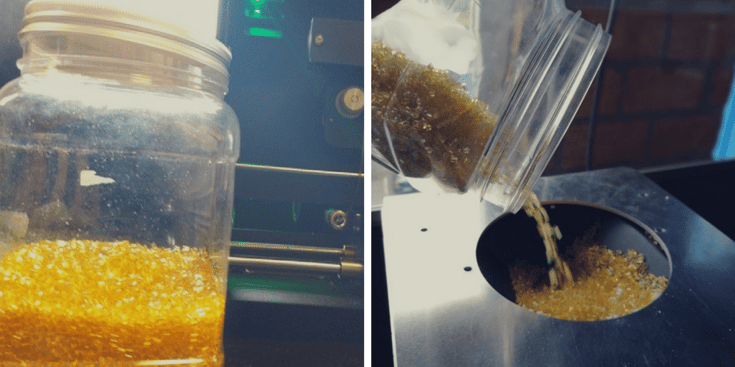

PEI resin (left) and adding it into the hopper (right)

First cleaning of the Filament Maker had to take place. Using ASACLEAN™ GL2, followed by ASACLEAN™ PX2, we were able to clean the device to prevent any impurities impacting the results. Once both materials had run through the device in order to properly clean it, the heaters were all set to the same temperature (160 °C).

Observation Indicators

There are three important things to look out for when extruding new filament for the first time:

- How does the filament look? Are there any signs of bubbles/holes, die lines, weld

lines, melt fracture or warpage? - Is the flow similar to that of standard PLA (when using the same rpm)?

- Is it possible to pull the material without any trouble (the material does not stick to

the puller wheel and does not break as a result of the force of the puller)?

Extrusion Summary

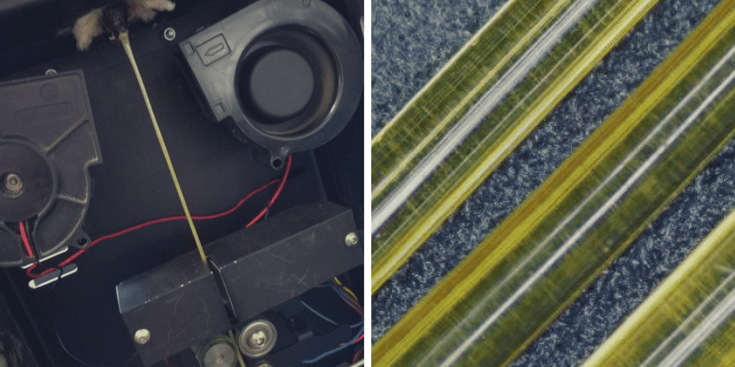

Extruding PEI (left) and the results (right)

After multiple tests, we concluded that PEI is able to be successfully extruded with the Filament Maker. The tests we ran determined that PEI should be extruded below 370 °C (but not too low) in order to prevent bubbles and holes from forming, and that proper cleaning methods should be used in order to determine the best results.

Conclusion

In the end, PEI was a very interesting polymer to test out compared to other ones we have tested in the past. Its high strength, rigidity and thermal stability meant that a lot of care had to be taken when running the tests. PEI though is a great filament and very useful, especially in aerospace and automotive applications.

Share this

- April 2024 (2)

- March 2024 (1)

- January 2024 (1)

- November 2023 (2)

- October 2023 (5)

- September 2023 (2)

- August 2023 (1)

- May 2023 (1)

- January 2023 (1)

- December 2022 (3)

- August 2022 (1)

- June 2022 (1)

- May 2022 (2)

- April 2022 (2)

- March 2022 (7)

- February 2022 (2)

- January 2022 (3)

- December 2021 (3)

- November 2021 (3)

- October 2021 (3)

- September 2021 (3)

- August 2021 (3)

- July 2021 (2)

- June 2021 (1)

- March 2021 (1)

- October 2020 (1)

- June 2020 (1)

- May 2020 (1)

- April 2020 (4)

- November 2019 (1)

- July 2019 (2)

- June 2019 (1)

- May 2019 (1)

- March 2019 (1)

- November 2018 (1)

- September 2018 (1)

- January 2018 (1)

- October 2017 (1)

- September 2017 (1)

- July 2017 (1)

- June 2017 (1)

- May 2017 (1)

- January 2017 (1)

- December 2016 (3)

- November 2016 (2)

- October 2016 (1)

- May 2016 (2)

- August 2015 (3)

- July 2015 (1)